Multi-chip integrated circuit packaging structure

A technology of integrated circuit and packaging structure, which is applied in the field of multi-chip integrated circuit packaging structure, and can solve problems such as flow and unstable connection at the bottom of the pins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

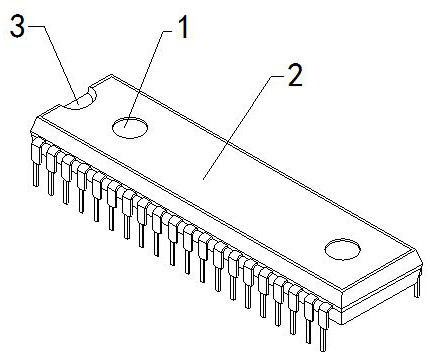

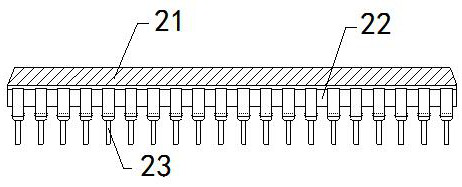

[0028] For example figure 1 -example Figure 5 Shown:

[0029] The present invention provides a multi-chip integrated circuit packaging structure, which structure includes a fixing hole 1, an integrated circuit board 2, and a card slot 3, the fixing hole 1 is fixed on the upper surface of the integrated circuit board 2, and the integrated circuit board 2 It is an integrated structure with the card slot 3; the integrated circuit board 2 includes an upper joint surface 21, a bottom board 22, and pins 23, and the bottom of the upper joint surface 21 is attached to the upper surface of the bottom board 22, The pins 23 are fixed at the front end of the bottom board 22 .

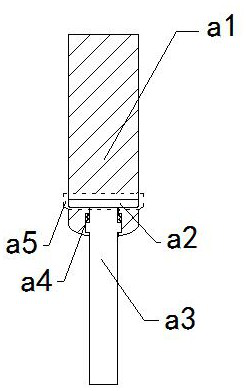

[0030] Wherein, the pin 23 includes an upper board a1, an upper slide a2, a force bar a3, an elastic strip a4, and a collection frame a5, the upper board a1 runs through the inner position of the collection frame a5, and the upper slide a2 The bottom of the upper plate is connected to the top of the force rod a...

Embodiment 2

[0036] For example Figure 6 -example Figure 9 Shown:

[0037] Wherein, the plate surface a24 includes a frame c1, a top sliding rod c2, a sliding plate c3, and a receiving plate c4, the frame c1 is embedded in the inner position of the receiving plate c4, and the top sliding rod c2 is slidingly matched with the inside of the frame c1 , the sliding plate c3 is engaged with the inside of the frame c1, and the rebound force generated by the mechanism shrinking to the extreme can make the top sliding rod c2 slide upwards and protrude along the frame c1 under the cooperation of the sliding plate c3, so that the top The slide bar c2 can be pushed away from the solidified resin block that is not formed into pieces on the receiving plate c4.

[0038] Wherein, the top sliding rod c2 includes a side swing plate c21, a lower fixing plate c22, a pull piece c23, and a middle connecting rod c24, the bottom of the side swing plate c21 is hinged to the bottom of the middle connecting rod c2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com