A manual self-integrated bullet blocking locking mechanism

A locking mechanism, an integrated technology, applied in the direction of launching devices, etc., can solve problems such as the use requirements of small launch boxes that are not suitable for multi-unit installation, the application limitations of the bullet blocking locking mechanism, and the inability to fully meet practical applications, etc., to improve functionality and The effect of reliability, transmission reliability improvement, and application cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

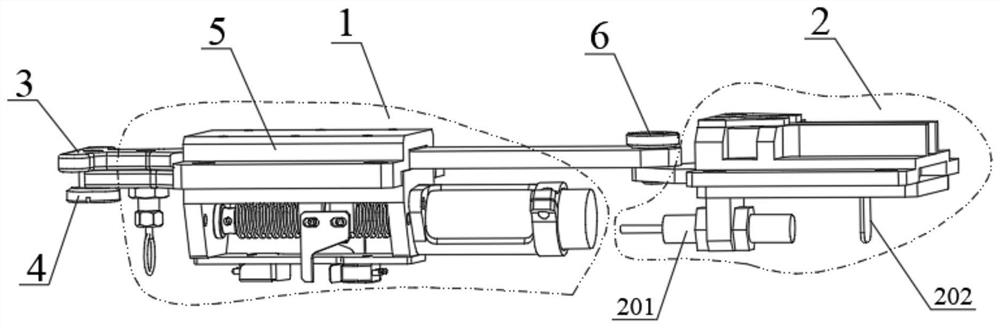

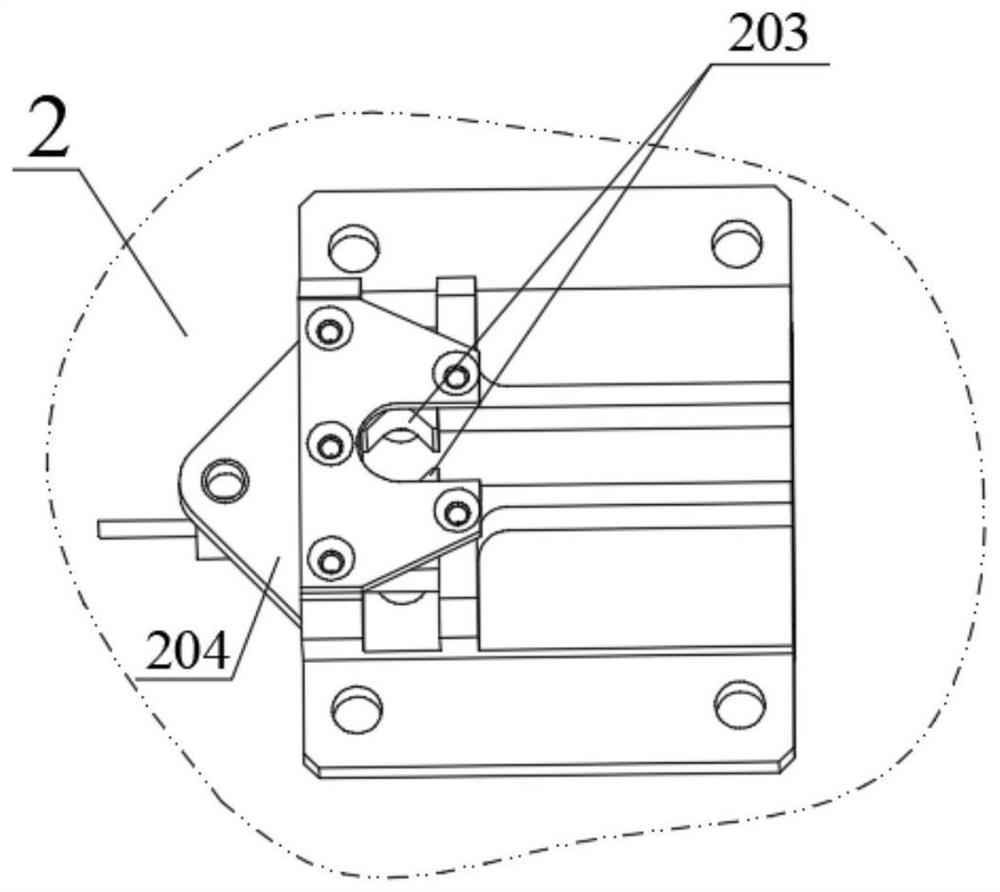

[0055] see Figures 1 to 17 In the preferred embodiment of the present invention, the hand-integrated bullet blocking and locking mechanism includes a lock bullet transmission assembly 1 , a lock bullet execution assembly 2 , a second sliding member 3 , an anti-fallout screw 4 , a cover plate 5 and a connecting screw 6 . Wherein, the lock bullet transmission assembly 1 and the lock bullet execution assembly 2 are matched correspondingly through the second sliding member 3, and the locking block 203 on the lock bullet execution assembly 2 can be driven correspondingly by the driving of the lock bullet transmission assembly 1 to the second sliding member 3, Complete the unlock or lock job process.

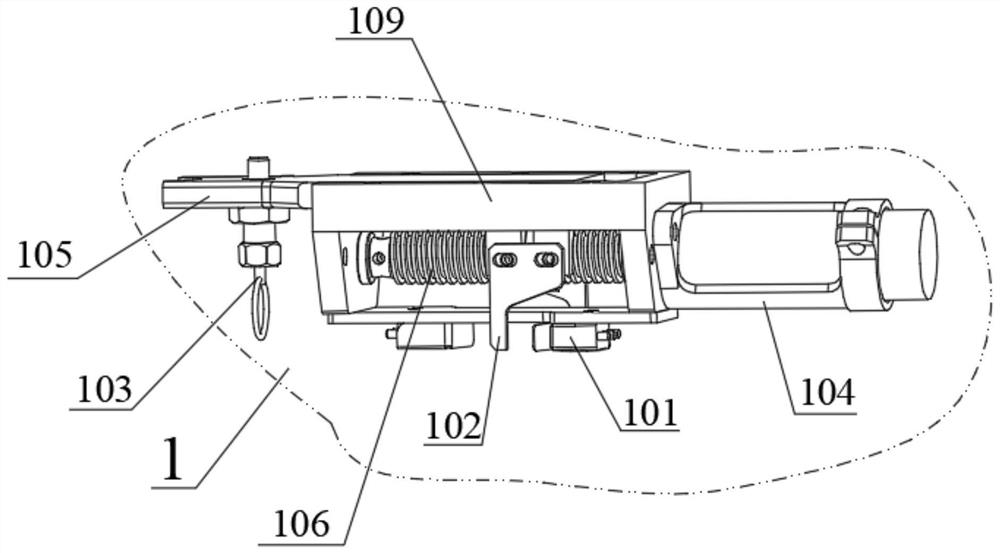

[0056] Specifically, see Figures 1 to 12 , the locking bolt transmission assembly 1 in the preferred embodiment includes a mounting seat 109 , a driving assembly 104 and a first sliding member 105 correspondingly disposed on the mounting seat 109 . Wherein, the corresponding drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com