Stall protection device based on centrifugal aerator

A protection device and aerator technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of wear and tear of parts, shortened service life of centrifugal aerators, and too fast rotation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

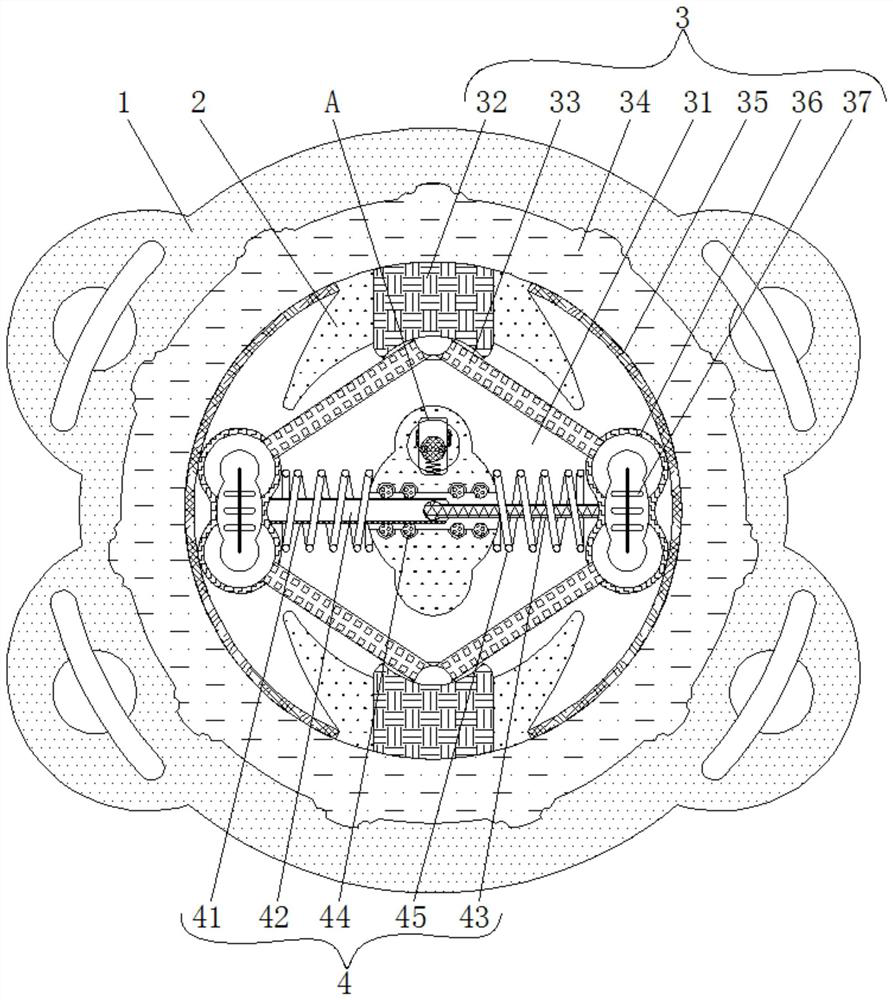

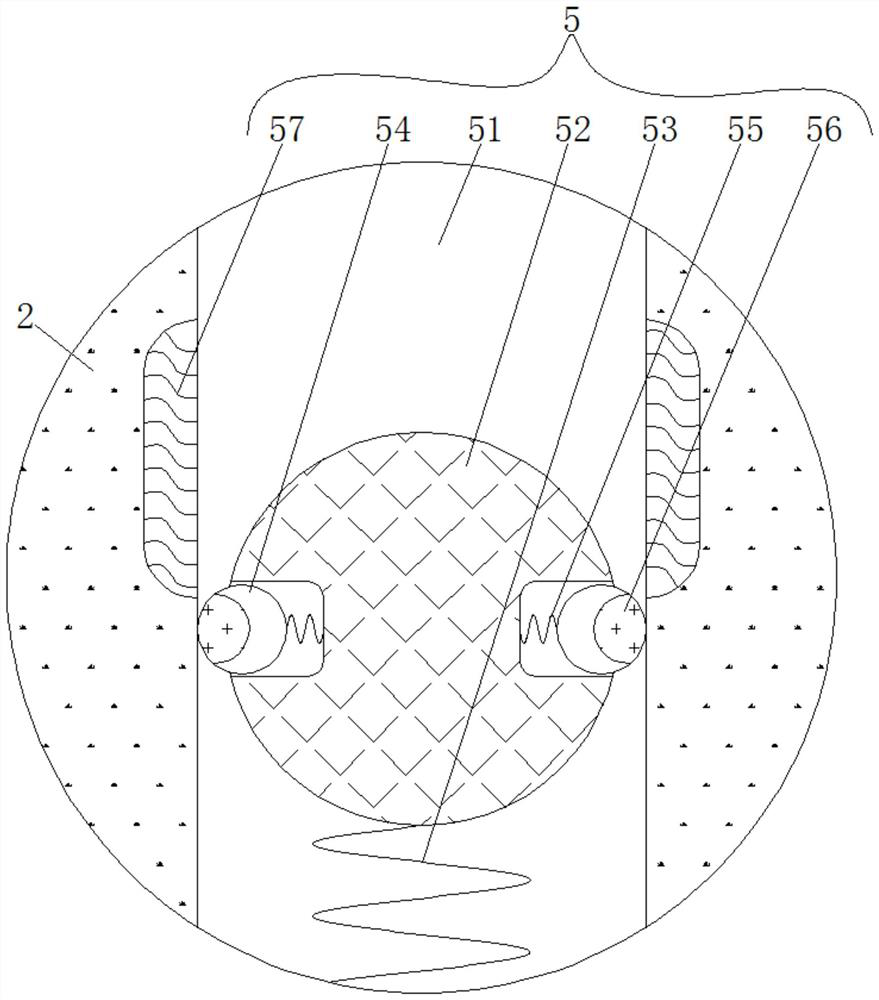

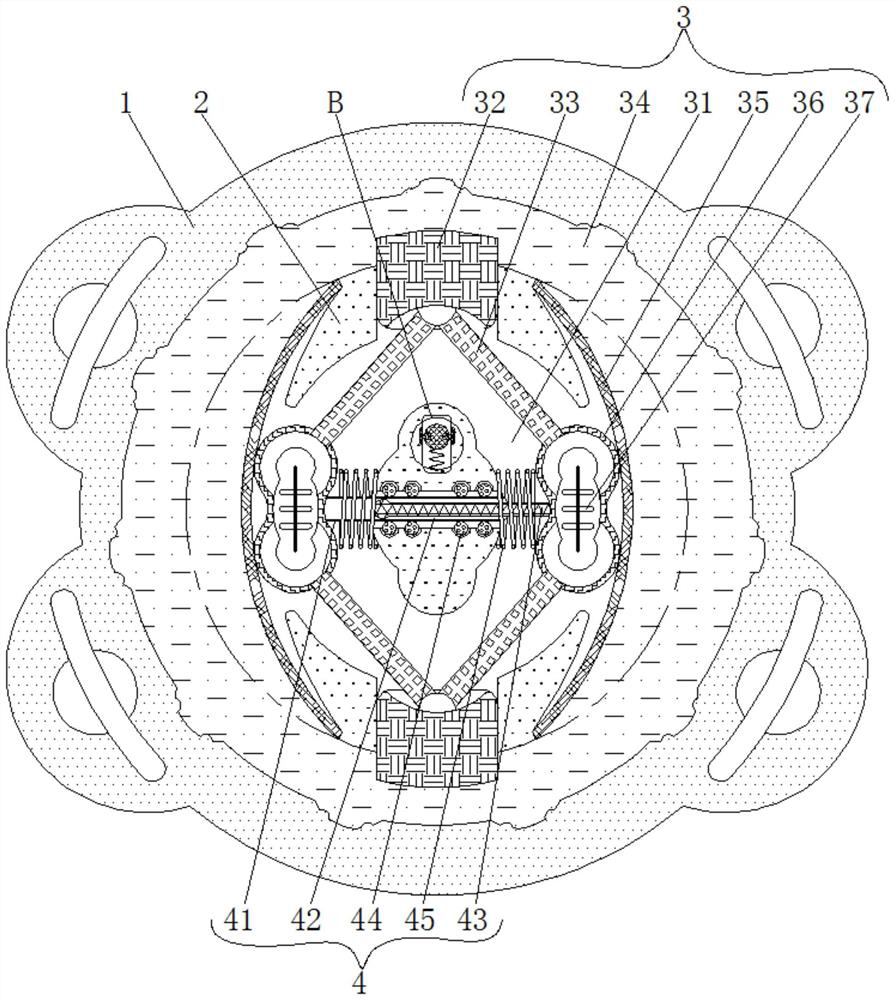

[0026] see figure 1 and figure 2 , a stall protection device based on a centrifugal aerator, including a main body 1, a rotating shaft 2, an actuator 3, a transmission mechanism 4 and a triggering mechanism 5, the inner side of the main body 1 is connected to the rotating shaft 2, and the inside of the rotating shaft 2 is movably connected to the actuator 3 and expand the rotating area of the rotating shaft 2 during work, the actuator 3 includes a movable groove 31, an extension part 32, a connecting rod 33, a fluid groove 34, a metal sheet 35, an inner retracting part 36 and an electromagnet 37, and the inside of the rotating shaft 2 is provided There is a movable groove 31, which plays a role in facilitating the movement of the actuator 3, and the top and bottom of the rotating shaft 2 are movably connected with an extension piece 32 slidingly connected to the outside of the activity groove 31, and the shape of the extension piece 32 is a rectangle And the material of th...

Embodiment 2

[0030] see Figure 1-4 , a stall protection device based on a centrifugal aerator, including a main body 1, a rotating shaft 2, an actuator 3, a transmission mechanism 4 and a triggering mechanism 5, the inner side of the main body 1 is connected to the rotating shaft 2, and the inside of the rotating shaft 2 is movably connected to the actuator 3 and expand the rotating area of the rotating shaft 2 during work, the actuator 3 includes a movable groove 31, an extension part 32, a connecting rod 33, a fluid groove 34, a metal sheet 35, an inner retracting part 36 and an electromagnet 37, and the inside of the rotating shaft 2 is provided There is a movable groove 31, which plays a role in facilitating the movement of the actuator 3, and the top and bottom of the rotating shaft 2 are movably connected with an extension piece 32 slidingly connected to the outside of the activity groove 31, and the shape of the extension piece 32 is a rectangle And the material of the protruding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com