Automatic heat sealing packaging machine used for bagged products

A heat-sealing and packaging machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of long-term use of overheating, inability to achieve mass production, low packaging efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

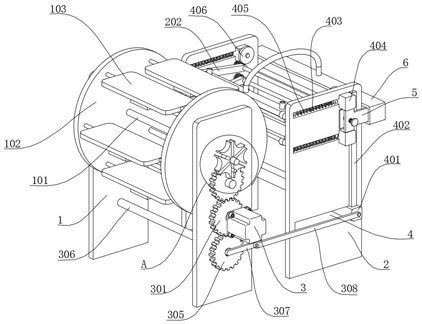

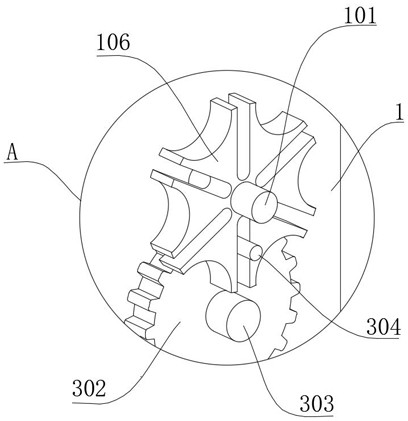

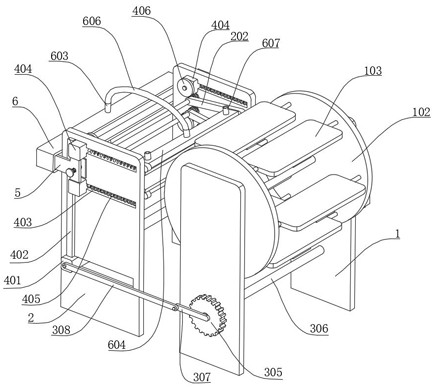

[0029] refer to Figure 1-10 , an automatic heat-sealing packaging machine for bagged products, comprising a first frame 1 and a second frame 2, a feeding mechanism is arranged between the first frame 1, and a heat sealing mechanism is arranged between the second frame 2 closed institutions, such as figure 1 and image 3 As shown, the first frame 1 and the second frame 2 are composed of two plates, wherein the space between the frames refers to the space between the two plates, and the outside of the frame is the part other than the space between the two plates. The mechanism includes two fixed rods 201 fixedly connected between the second frame 2, and each fixed rod 201 is connected with two rotating plates 202 through bearings for rotation, and the rotating plate 202 is fixedly connected with the second frame 2 There is a torsion spring 203, and the lower surfaces of the corresponding two rotating plates 202 are jointly fixedly connected with a heat-sealing plate 204, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com