Building wall offset detection device

A detection device and technology for building walls, which can be used in measuring devices, surveying and navigation, and measuring inclination, etc., which can solve the problems of inconvenient work for workers to repair the wall, large distance between installation holes, and wall detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

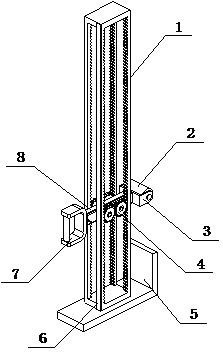

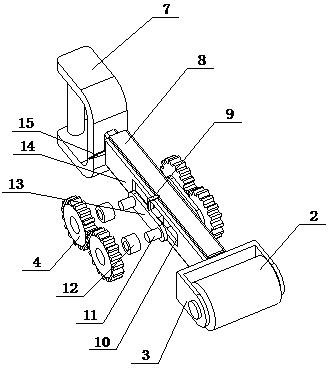

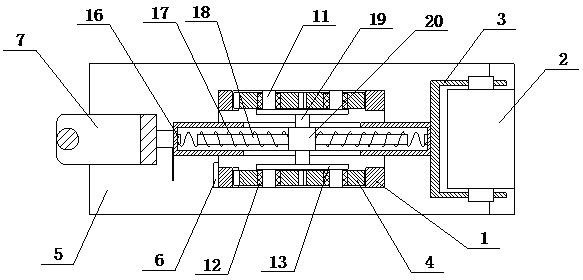

[0025] A building wall offset detection device of the present invention is realized in the following way: a building wall offset detection device of the present invention is composed of a support device, a detection device and a rolling device, and the support device is composed of a fixed rack seat (1) , the base (5) and the longitudinal measuring ruler (6), the fixed rack seat (1) is placed on the base (5), the longitudinal measuring ruler (6) is placed on the fixed rack seat (1), the base ( 5) There is an anti-slip pad at the bottom, and the fixed rack seat (1) has multiple sets of racks built in. The measuring device consists of a measuring roller (2), a roller support frame (3), a handle (7), and a horizontal measuring ruler ( 8), horizontal measuring pointer (9), through hole (10), connecting plate (13), measuring slider (14), longitudinal measuring pointer (15), sound alarm (16), spring (17), touch rod (18), connecting rod (19) and slider (20), the horizontal measuring ...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is: the measuring roller (2) can be replaced by a plurality of measuring wheels (22), and the plurality of measuring wheels (22) are equidistantly placed on the rotating shaft, and the rotating shaft The two ends are connected to both sides of the roller support frame (3) through bearings (12), and the measuring wheel (22) has an annular groove; when in use, it can reduce the contact with the wall, thereby reducing the error.

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is: the top and bottom sides of the roller support frame (3) are respectively provided with one end of an auxiliary support rod, and the two ends of the roller pass through the bearings (12) and two adjacent The other end of the auxiliary support rod is connected, and the auxiliary support wheel (23) is placed on the roller; when in use, it can guide the measuring roller (2) and at the same time make the device more stable during measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com