A Design Method of Elliptical Throat Offset Pneumatic Vectoring Nozzle

A technology of vector nozzle and design method, applied in machine/engine, jet propulsion device and other directions, can solve the problems that the shape of the circular outlet is not suitable for the flat body, it is difficult to realize the integrated design of the aircraft, and it is difficult to realize the flexible control of the aircraft, etc. Achieve strong air combat advantages, improve infrared stealth performance, and enhance maneuverability and flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

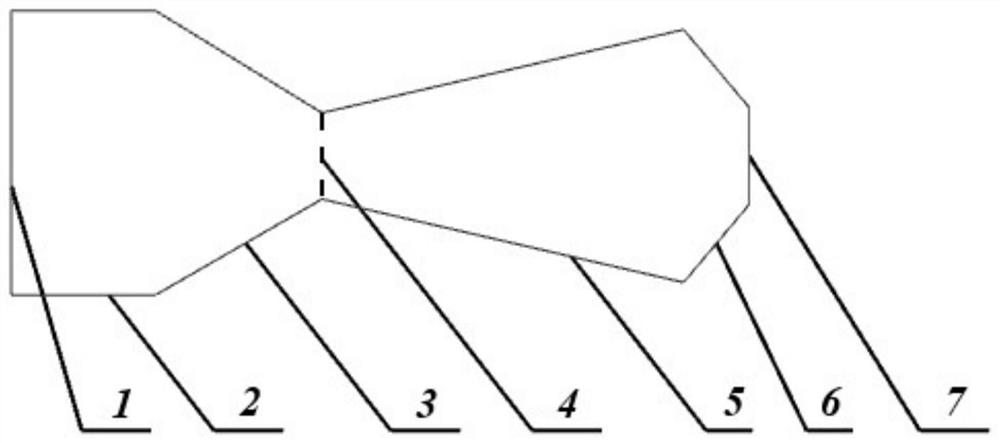

[0061] Adaptive passive oval throat offset aerodynamic vectoring nozzle for typical configurations.

[0062] Figure 7 Shown is NPR=6, T in the non-vector state 0 * = 300K, b / a=1 and b / a=0.6, the two kinds of dual throat vector nozzle (Dual Throat Nozzle, referred to as DTN) nozzle outlet jet flow along the cross-section flow direction vorticity contour, in which the outlet flow field along the The development direction of the jet flow is a Y-Z plane slice with a set of dimensionless distances X / L=0, 0.5, 1, 1.5, 2.5, and the dimensionless distance X / L represents the ratio of the distance X between the slice and the outlet of the nozzle and the total length L of the nozzle. The figure shows the flow direction vorticity nephogram of the nozzle exit jet slice along the section. The jet exchanges momentum and heat with the ambient gas under the interaction of flow direction vortex and reverse vortex, and the vortex scale gradually decays along the flow direction. Comparing the...

Embodiment 2

[0065] Adaptive passive oval throat offset aerodynamic vectoring nozzle for typical configurations.

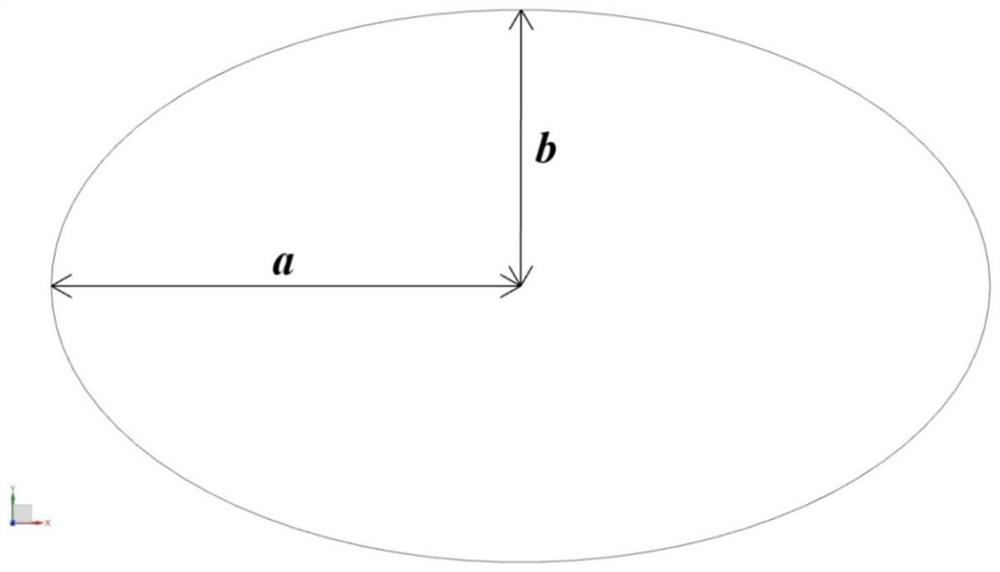

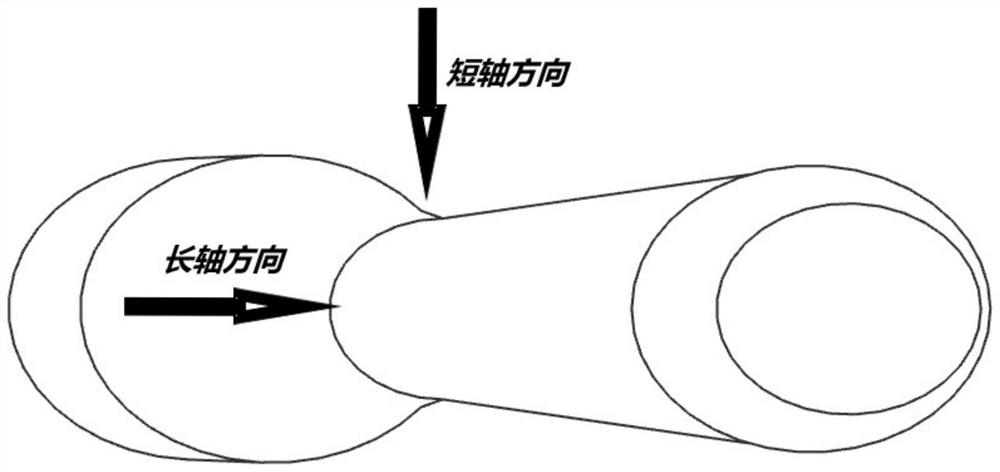

[0066] Figure 9 Shown is the elliptical nozzle with short-to-longer-diameter ratios of b / a=1.0, b / a=0.8, b / a=0.6, b / a=0.4 in the non-vector state in the range of falling pressure ratio (NPR) 2-10 Thrust coefficient change curve in . It can be seen that the smaller b / a is, the higher the thrust coefficient is.

[0067] Figure 10 Shown are the elliptical nozzles with short-to-longer-diameter ratios of b / a=1.0, b / a=0.8, b / a=0.6, b / a=0.4 falling in different positions of the bypass channel in the vector state Thrust coefficient variation curve for pressure ratio (NPR) variation. In the figure, long indicates that the bypass channel is arranged in the direction of the long axis of a throat, and short indicates that the bypass channel is arranged in the direction of the short axis of a throat. It can be seen from the figure that, contrary to the results of the non-vector state,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com