Electric unlocking and counter locking mechanism

A technology for unlocking and driving mechanisms, applied in the field of electronic locks, can solve problems such as high energy consumption, no buffer design for the mechanism, and motor damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

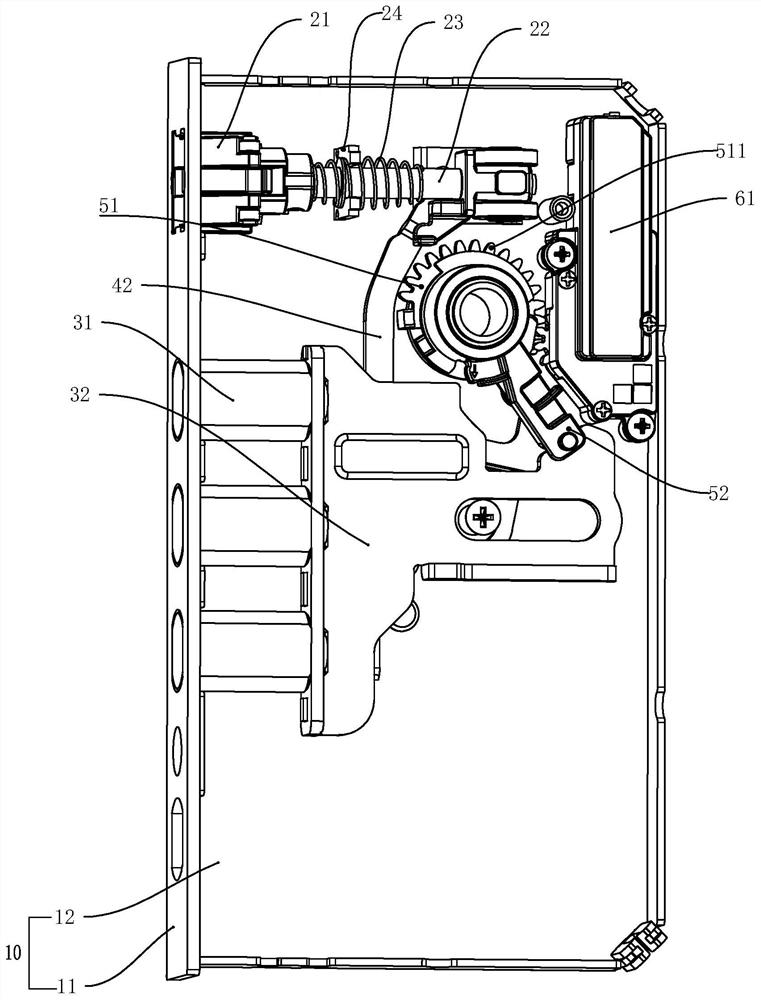

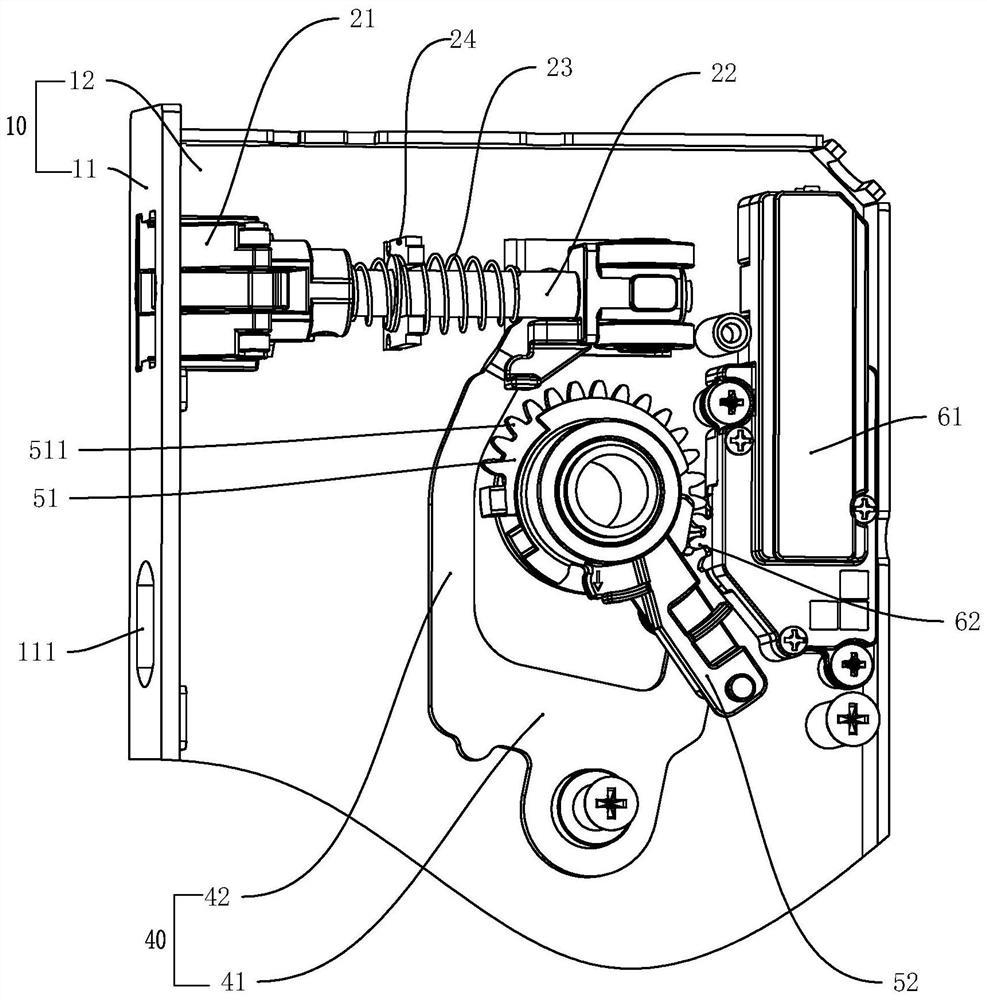

[0024] The first embodiment, such as Figure 1 to Figure 9 As shown, an electric unlocking and anti-locking mechanism includes a lock box 10, a bolt assembly 20, a main tongue assembly 30, a paddle assembly 40, a fork assembly 50 and a driving mechanism 60, and the lock box 10 includes a side plate 11 and a bottom plate 12. The side plate 11 is penetrated with a bolt hole and a main tongue hole 111; the bolt assembly 20 includes a bolt 21, a bolt connector 22 and a return spring 23 sleeved outside the bolt connector 22, and resets The spring 23 is in a compressed state, and the latch tongue 21 automatically stretches out of the latch tongue hole under the action of the return spring 23; the main tongue assembly 30 includes a main tongue 31 and a main tongue push plate 32, and one end of the main tongue push plate 32 is connected to the main tongue 31 is fixedly connected, and the other end is slidably connected with the bottom plate 12; the paddle assembly 40 includes a paddle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com