Electrolyte flow and pressure control method and system for dynamic hydrogen production electrolytic bath

A technology of pressure control and electrolysis current, applied in the direction of electrolysis process, electrolysis components, energy input, etc., can solve the problems of accelerating equipment and material loss, increasing operating costs, gas accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

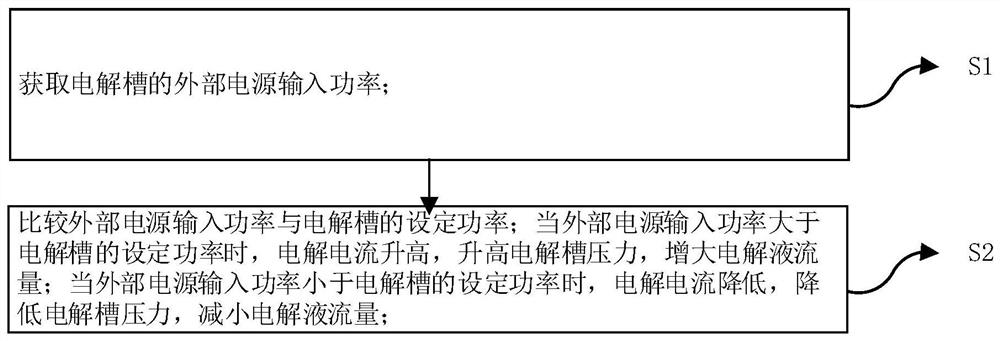

[0034] see figure 1 As shown, the electrolyte flow rate and pressure control method of a dynamic hydrogen production electrolyzer of the present invention comprises the following steps:

[0035] S1. Obtain the input power of the external power supply of the electrolyzer;

[0036] S2. Compare the input power of the external power supply with the set power of the electrolytic cell; when the input power of the external power supply is greater than the set power of the electrolytic cell, the electrolytic current increases, the pressure of the electrolytic cell is increased, and the flow rate of the electrolyte is increased; when the external power input When the power is less than the set power of the electrolytic cell, the electrolytic current decreases, the pressure of the electrolytic cell is reduced, and the flow of the electrolyte is reduced;

[0037] The set power is the rated power of the electrolytic cell; the electrolytic current is X% of the rated current of the electro...

Embodiment 2

[0044] On the basis of embodiment 1, this embodiment also includes the following steps:

[0045] Monitor the content of hydrogen in the oxygen prepared by the electrolyzer; when the volume of hydrogen in the oxygen is greater than or equal to 1.5%, reduce the pressure of the electrolyzer and reduce the flow rate of the electrolyte until the content of hydrogen in the oxygen prepared by the electrolyzer is less than 1.5%.

[0046] Pressure and electrolyte flow control are also affected by the purity of the oxygen produced by the electrolyzer: as the oxygen purity decreases, the pressure decreases and the electrolyte flow decreases to reduce gas permeation through the membrane and blending through the electrolyte.

Embodiment 3

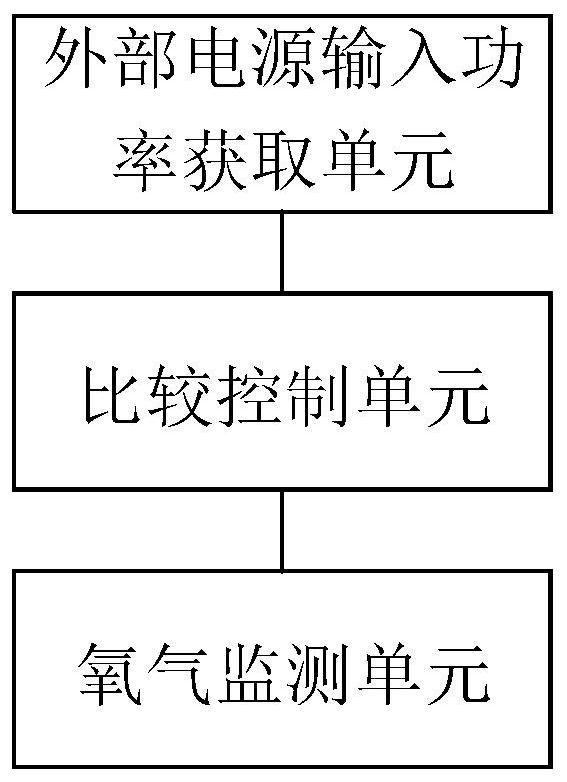

[0048] see figure 2 As shown, the electrolyte flow rate and pressure control method of a dynamic hydrogen production electrolyzer of the present invention comprises the following steps:

[0049] S1. Periodic sampling to obtain the input power of the external power supply of the electrolyzer;

[0050] S2. Compare the input power of the external power supply with the set power of the electrolytic cell; when the input power of the external power supply is greater than the set power of the electrolytic cell, the electrolytic current increases, the pressure of the electrolytic cell is increased, and the flow rate of the electrolyte is increased; when the external power input When the power is less than the set power of the electrolytic cell, the electrolytic current decreases, the pressure of the electrolytic cell is reduced, and the flow of the electrolyte is reduced;

[0051] The set power is the rated power of the electrolytic cell; the electrolytic current is X% of the rated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com