Multi-stage purification treatment process for industrial wastewater

A technology for industrial wastewater and treatment process, applied in water/sewage multi-stage treatment, water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of discount of purification effect, blockage of pores, and reduction of scum floating rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

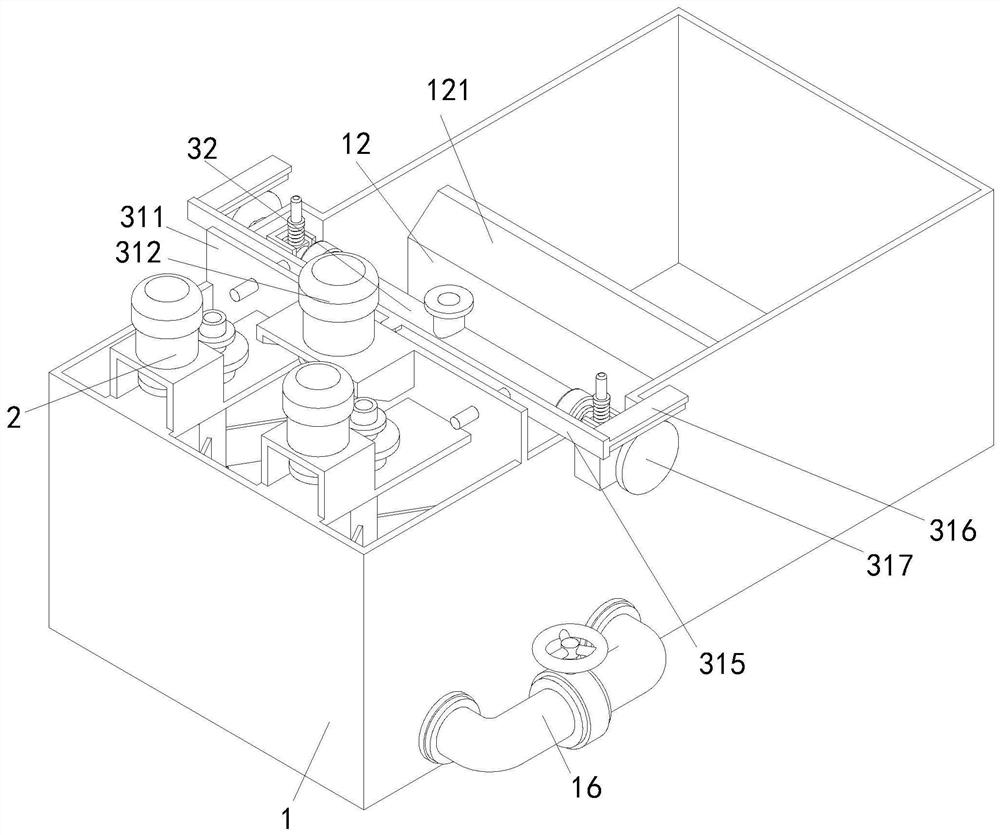

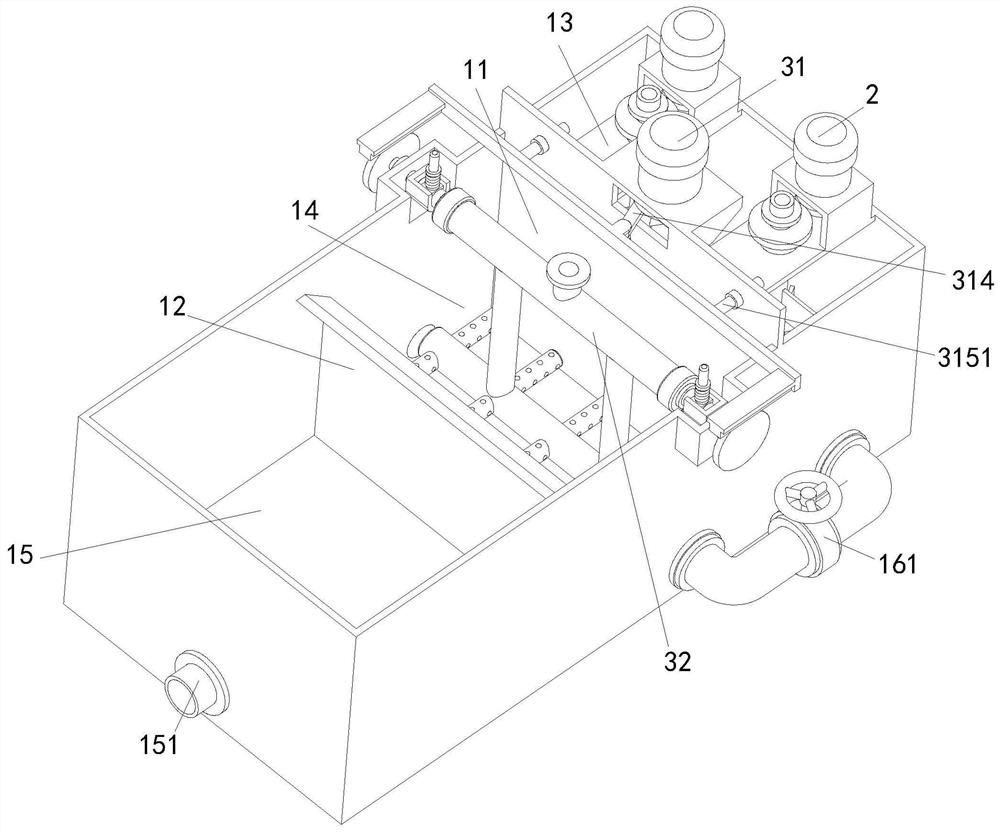

[0040] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

[0041] See attached Figure 1-8 As shown, a multi-stage purification treatment process for industrial wastewater, the treatment process specifically includes the following steps:

[0042] S1. Remove the precipitated impurities from the wastewater produced by industrial production through static precipitation;

[0043] S2. Pass the wastewater after the sedimentation treatment in step S1 into the flocculation zone 13 of the industrial wastewater purification treatment system, add flocculant and coagulant aid in the flocculation zone 13, and stir the wastewater by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com