Integrated bonding, positioning and pressing tool for small web on trailing edge of windward side of wind power blade

A technology of wind turbine blades and windward surface, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of high labor intensity, affecting the bonding quality and positioning effect of small webs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the implementation of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

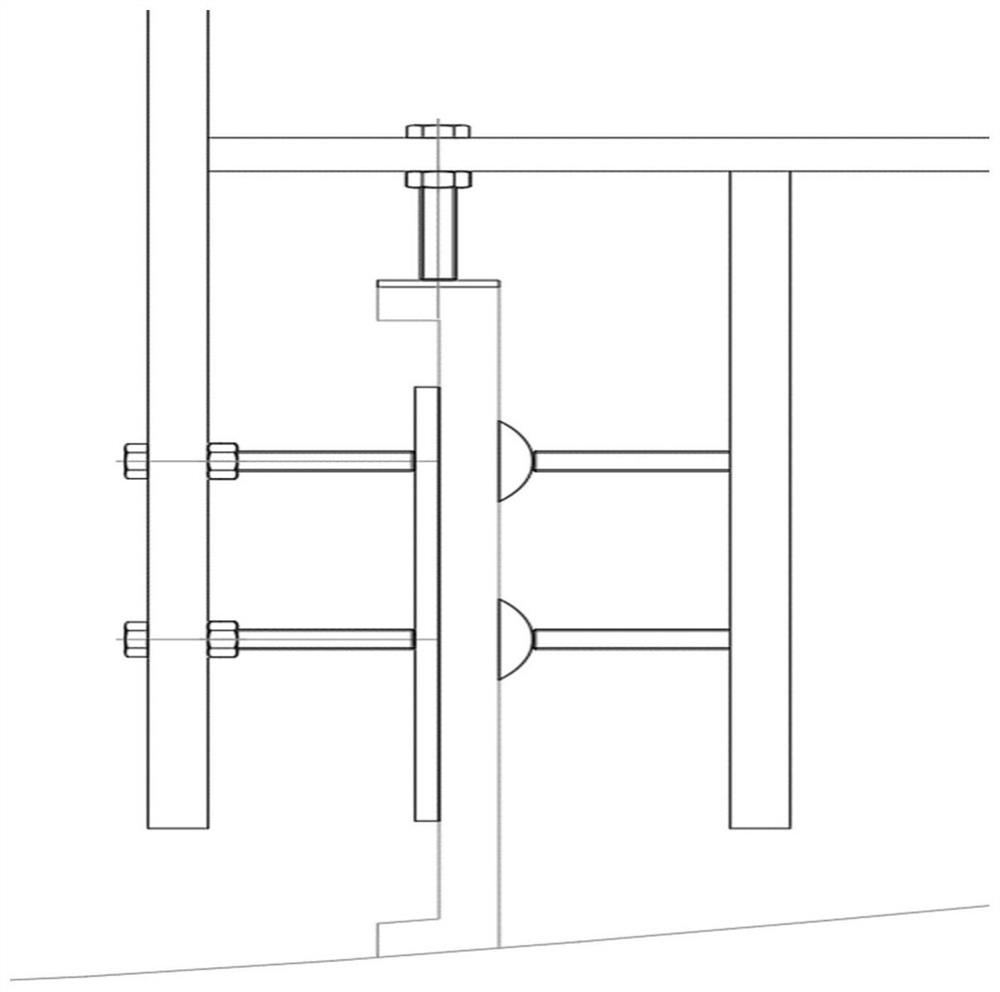

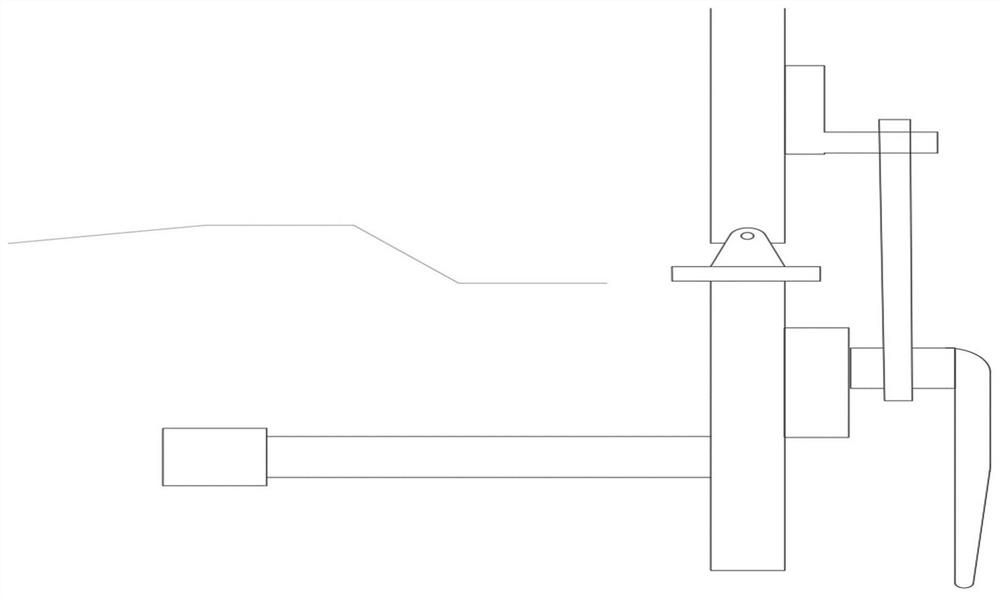

[0022] like figure 1 As shown, the present invention provides a wind power blade trailing edge 7 small web integrally bonded positioning press down tooling, which includes a leg frame 1, a vertical bracket 13 for a fixed vacuum adsorption plate, and a verticality ejector bracket for a fixed web 14. Connect the horizontal chord-direction positioning bracket 6, press down the adjusting screw 3, and fix the vertical support 13 of the vacuum suction plate along the vertical direction. There are vacuum suction plate legs 12 and vacuum suction plate 2 on the support for the lifting process of the small web Carry out vacuum adsorption in; fixed web perpendicularity ejector support 14 is arranged along the vertical direction, there is fixed web verticality ejector leg 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com