Nomadic prefabricated slab production device facilitating stacking of mold tables

A technology of production equipment and prefabricated panels, which is applied in the fields of freight vehicles, manufacturing tools, transportation and packaging, etc. It can solve the problems of low stacking automation, time-consuming and labor-intensive efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

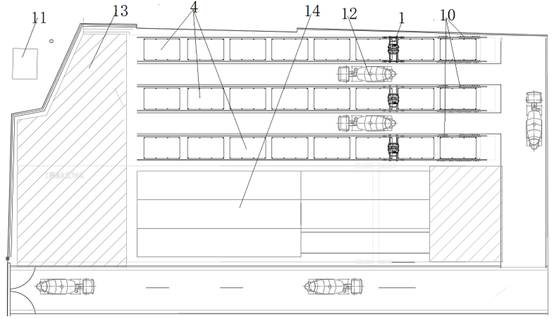

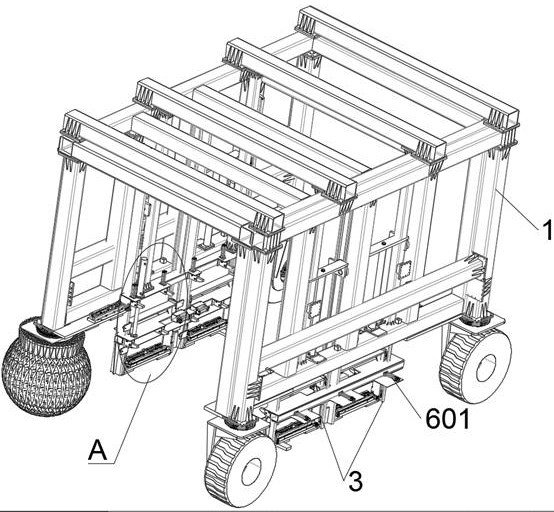

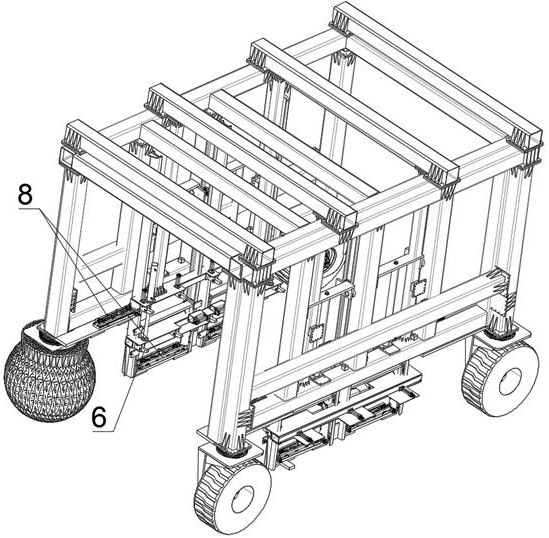

[0034] Such as figure 1 As shown, a nomadic prefabricated panel production device that facilitates the stacking of mold tables includes multiple rows of mold table racks, and mold tables 4 are arranged on the mold table racks, and each row of mold tables is placed A steam curing device 10 is provided at the end of the rack, and a mixing area 11, a concrete transport device 12, a raw material placement area 13 and a product placement area 14 are arranged around the mold table rack, and between the mold table and the steam curing device A mold table stacking device is provided, and the mold table stacking device includes a movable outer frame 1, and steering wheels are provided at the lower end of the outer frame 1, one of which is a spherical roller for easy steering; There is a control room 2 and an up and down movement mechanism 3, on which a positioning adjustment mechanism 5 and a clamping mechanism 6 for the mold table 4 are arranged, and a mold table placement frame, a st...

Embodiment 2

[0043] Such as figure 1 As shown, a nomadic prefabricated panel production device that facilitates the stacking of mold tables includes multiple rows of mold table racks, and mold tables 4 are arranged on the mold table racks, and each row of mold tables is placed A steam curing device 10 is provided at the end of the rack, and a mixing area 11, a concrete transport device 12, a raw material placement area 13 and a product placement area 14 are arranged around the mold table rack, and between the mold table and the steam curing device A mold table stacking device is provided, and the mold table stacking device includes a movable outer frame 1, and steering wheels are provided at the lower end of the outer frame 1, one of which is a spherical roller for easy steering; There is a control room 2 and an up and down movement mechanism 3, on which a positioning adjustment mechanism 5 and a clamping mechanism 6 for the mold table 4 are arranged, and a mold table placement frame, a st...

Embodiment 3

[0052] Such as figure 1 As shown, a nomadic prefabricated panel production device that facilitates the stacking of mold tables includes multiple rows of mold table racks, and mold tables 4 are arranged on the mold table racks, and each row of mold tables is placed A steam curing device 10 is provided at the end of the rack, and a mixing area 11, a concrete transport device 12, a raw material placement area 13 and a product placement area 14 are arranged around the mold table rack, and between the mold table and the steam curing device A mold table stacking device is provided, and the mold table stacking device includes a movable outer frame 1, and steering wheels are provided at the lower end of the outer frame 1, one of which is a spherical roller for easy steering; There is a control room 2 and an up and down movement mechanism 3, on which a positioning adjustment mechanism 5 and a clamping mechanism 6 for the mold table 4 are arranged, and a mold table placement frame, a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com