Pump cylinder honing tool

A honing and tooling technology, which is applied in the field of oil production engineering, can solve problems such as the inability to accurately guarantee the straightness of the pump barrel and the forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

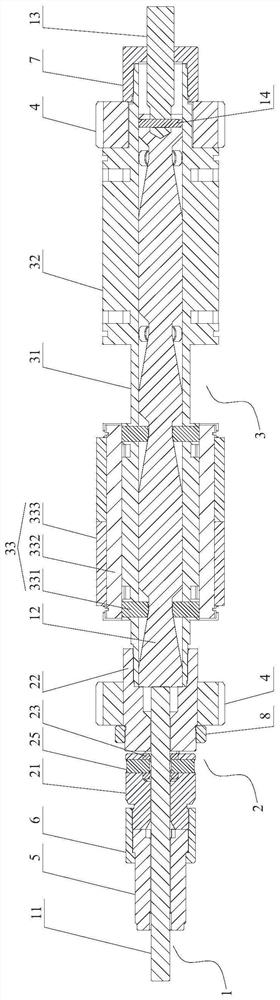

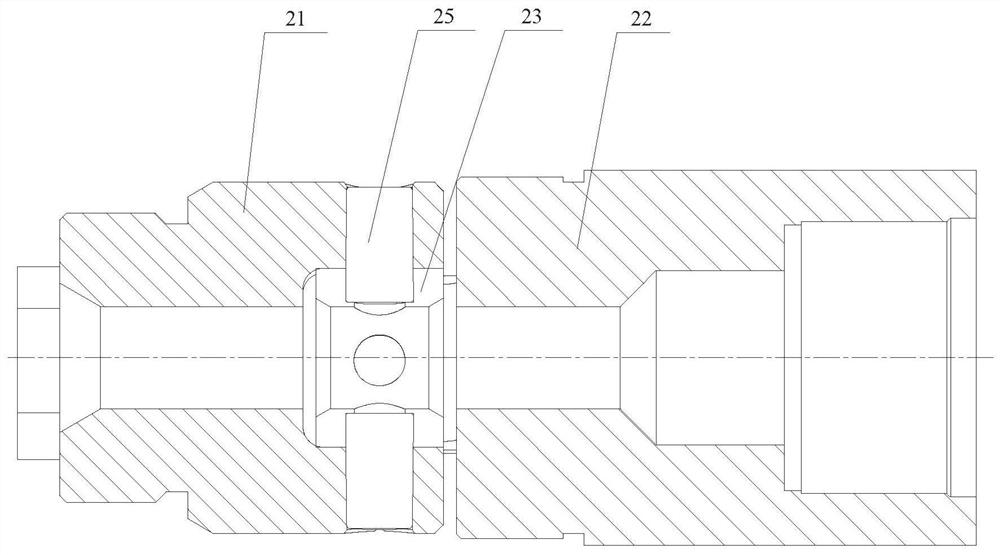

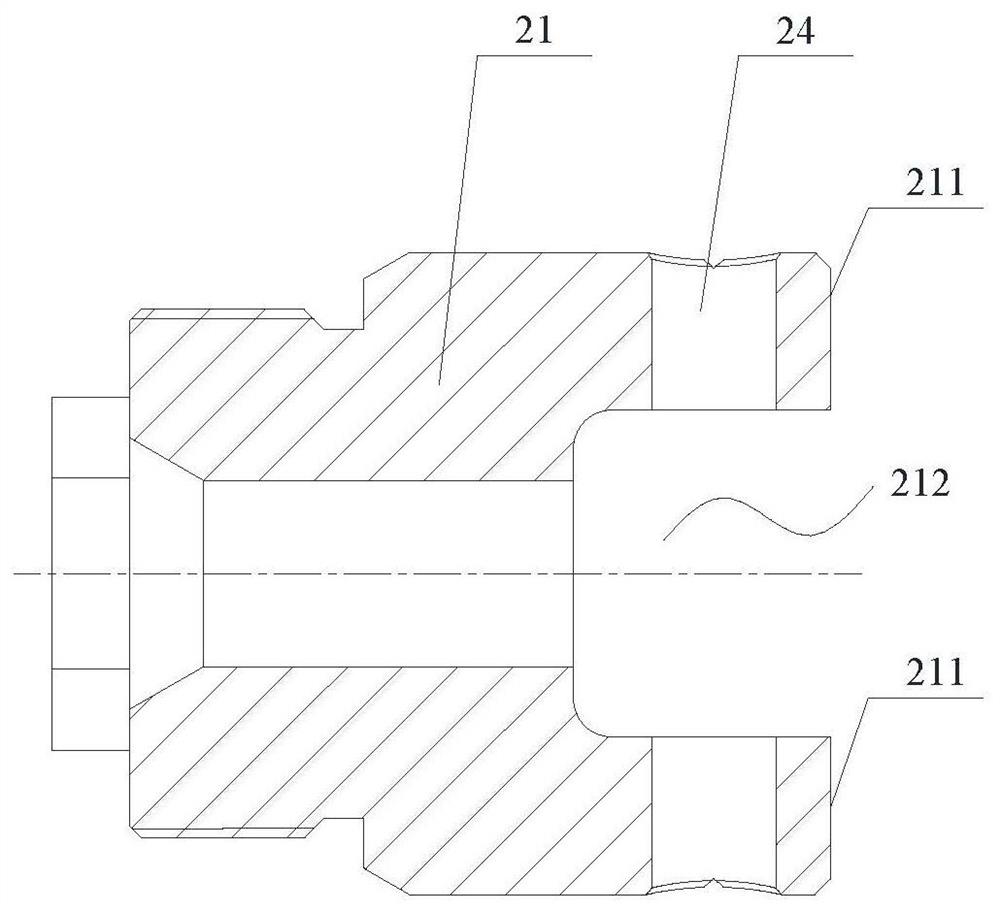

[0068] Such as figure 1 As shown, the present invention provides a pump barrel honing tool, wherein the pump barrel honing tool includes a mandrel part 1, a universal coupling part 2 and a honing part 3, and the mandrel part 1 includes a push rod 11 and an expanding core 12, The universal joint 2 includes a connected first universal joint 21 and a second universal joint 22, an angle can be formed between the axis of the first universal joint 21 and the axis of the second universal joint 22, and the honing part 3. It includes a tubular body 31. At least two honing heads 32 are protrudingly formed on the outer surface of the body 31. Each honing head 32 is provided with a plurality of honing bars 33 arranged at intervals along i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com