Axial-flow pump with anti-blocking function

An anti-clogging, axial-flow pump technology, which is applied to parts, pumps, and pump elements of elastic fluid pumping devices, can solve the problems of reduced pumping efficiency, failure to discharge, and many impurities, and achieve increased pumping efficiency , Eliminate rotational movement, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

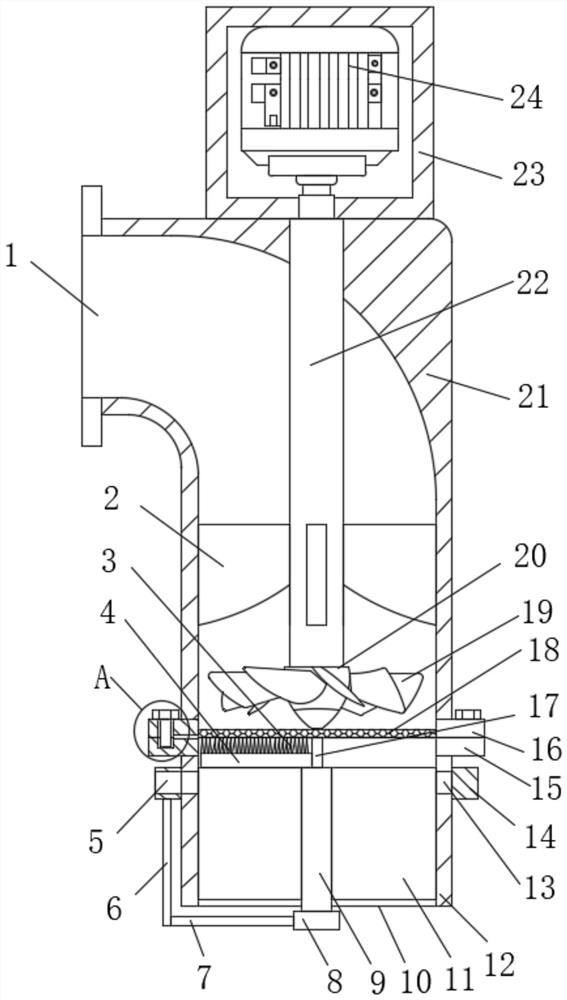

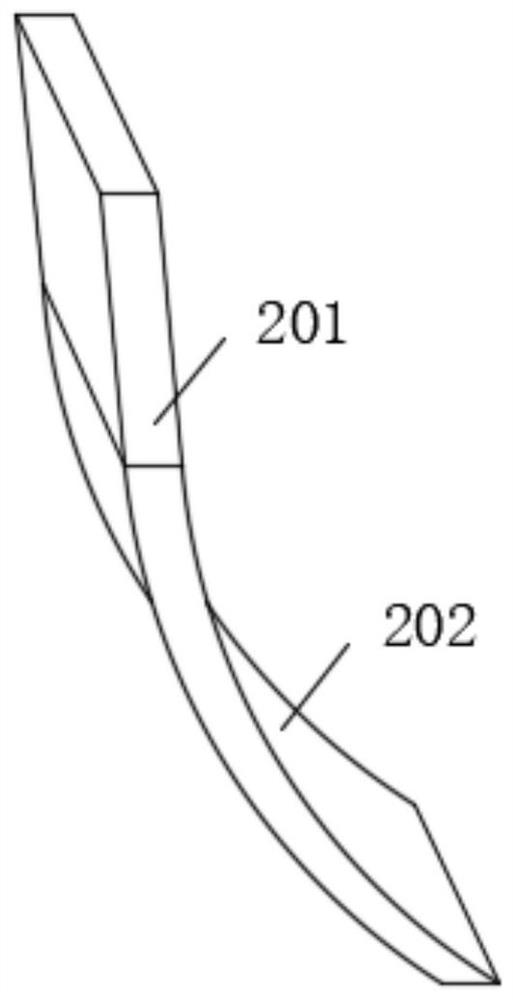

[0030] Refer Figure 1-7 , Having an anti-clogging of the flow pump comprising a pump body 21 and the connecting pipe 12, the connection pipe 12 is located below the pump body 21, the connecting pipe 12 and the inlet end of the pump body 21 is provided with a connection assembly for connection, the bottom of the connecting tube 12 defines a water inlet 10, the side of the pump body 21 defines a water outlet, the pump body 21 is fixedly connected with the first strainer 18, the top of the pump body 21 is fixedly connected with the drive box 23, drive the top of the inner wall of the case 23 fixedly connected with a servo motor 24, the output shaft of the servo motor 24 extends inside the pump body 21 and is fixedly connected with a rotation shaft 22, fixed to the outer wall of the shaft sleeve 22 is provided with a mounting cylinder 20, the outer wall of the mounting cylinder 20 is provided impeller 19, connecting tube 12 is provided with an internal filter assembly for filtering im...

Embodiment 2

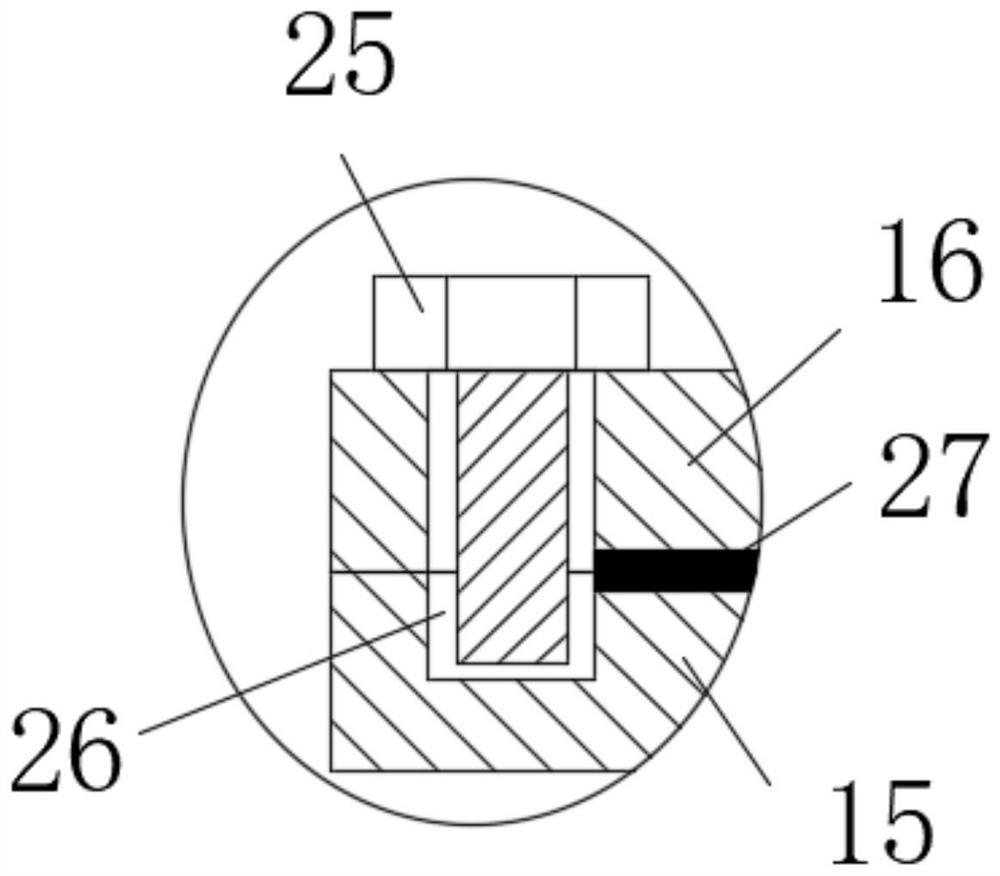

[0032] Refer Figure 1-7, Having an anti-clogging of the flow pump comprising a pump body 21 and the connecting pipe 12, the connection pipe 12 is located below the pump body 21, the connecting pipe 12 and the inlet end of the pump body 21 is provided with a connection assembly for connection, the connector assembly comprises a fixed pump body 21 connected to the bottom of the connecting block 16 and the connecting pipe 12 at the top of block 15, the connecting block 16 is connected to an internally threaded bolt 25, the head block 15 is fitted with a connection opening 25 with bolts screw groove 26 used for connecting the connection pipe 12 and pump 21, to facilitate subsequent removal, a first filter 18 for cleaning or replacement, the connecting block 16 and between the connecting block 15 is provided with a rubber ring 27 with a , sealing means for ensuring a top, a bottom connector tube 12 defines a water inlet 10, the side of the pump body 21 defines a water outlet, the pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com