Thermal insulation straight hole injection-production Y joint and using method thereof

A technology of straight holes and inner holes, which is applied in the field of heat insulation, allowing steel wire or cable operation devices, and can solve problems such as lack of heat insulation function, lack of heat insulation function, failure of electric submersible pump cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

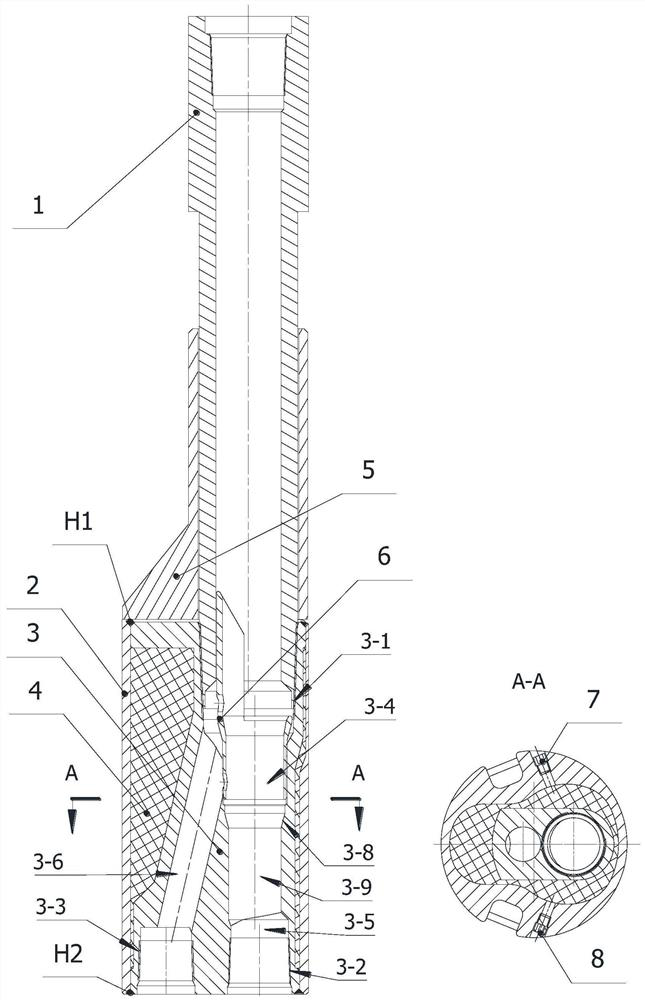

[0040] A heat-insulating straight-hole injection-production Y joint, including a lifting sub-section 1, an outer shell 2, an inner core 3, an upper guide shoe 5 and an inner guide shoe 6, the inner core 3 is set in the outer shell 2, and the tail end of the lifting sub-joint 1 extends into the The shell 2 is threadedly connected to the inner wall of the head end of the inner core 3, and the upper guide shoe 5 is installed on the head end of the outer shell 2, and the tail end of the upper guide shoe 5 is welded and fixed to the head end of the inner core 3, and the tail end of the outer shell 2 is connected to the inner core 3. The tail end is welded and fixed, and a packing cavity is formed between the inner wall of the shell 2 and the outer wall of the inner core 3, and the packing cavity is filled with filler 4;

[0041] The inner core 3 is a "Bu"-shaped structure, and an upper boss 3-11 and a lower boss 3-10 are integrally provided at both ends of the inner core 3 respectiv...

Embodiment 2

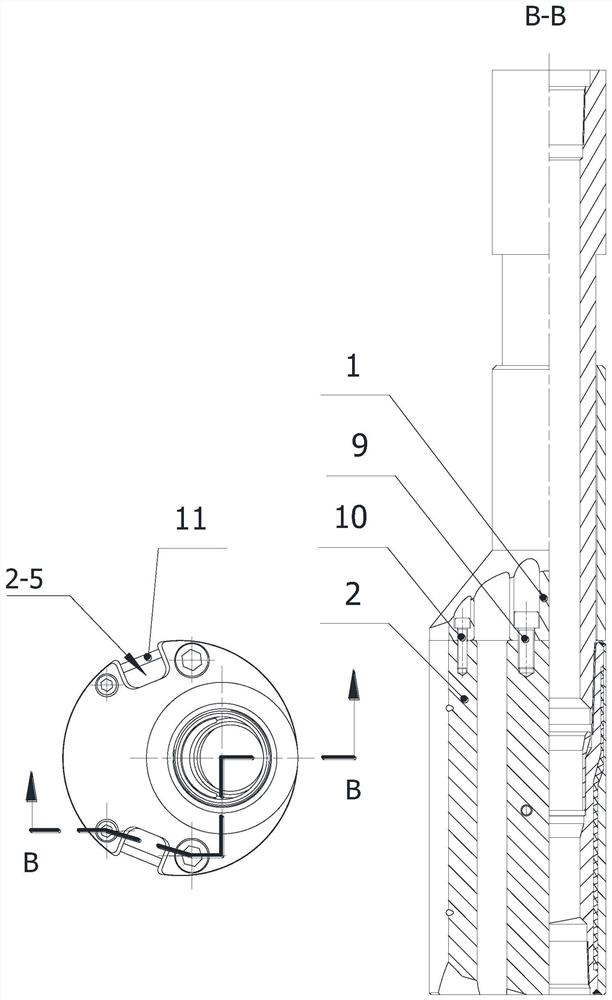

[0043] On the basis of Embodiment 1, the head end of the inner guide shoe 6 forms an inner guide shoe guide slope 6-1, and an inner guide shoe inner cylindrical surface 6-4 is formed below the inner guide shoe guide slope 6-1. The guide inclined surface 6-1 and the outer wall of the inner cylindrical surface 6-4 of the inner guide jointly form an outer cylindrical surface 6-6 of the inner guide shoe, and an upper circle of the inner guide shoe is provided on the outer cylindrical surface 6-6 of the inner guide shoe. The holes 6-7 and the round holes 6-8 under the inner guide shoe are used to pass part of the production liquid to prevent impurities from settling on the top of the production plug 12 during the production process, which will cause difficulties in salvaging the production plug 12. The inner cylinder of the inner guide shoe An inner shoe inner hole 6-2 is formed below the surface 6-4, and an inner shoe connecting thread 6-1 is formed on the outer wall of the inner s...

Embodiment 3

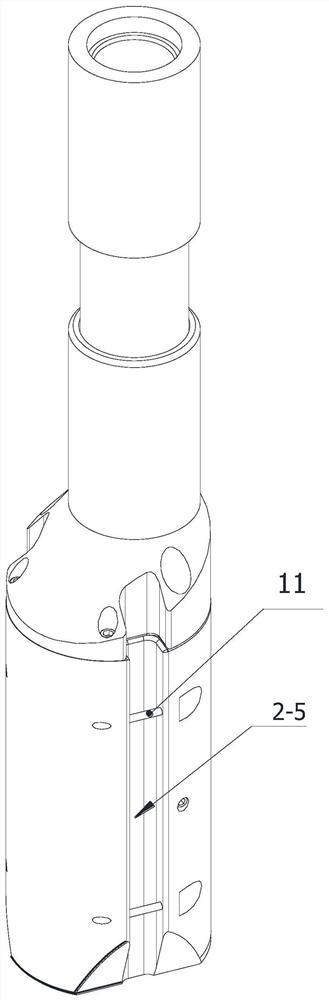

[0045] On the basis of Embodiment 2, the shell 2 adopts a hollow tubular structure, and the upper surface of the head end of the shell 2 is provided with an internal threaded hole 2-1 and an external threaded hole 2-2 of the shell, and the inner wall of the shell 2 is sequentially arranged from top to bottom. The upper inner surface 2-7 of the housing and the lower inner surface 2-6 of the housing are formed, and the outer wall of the housing 2 is symmetrically provided with cable grooves 2-5, and the side wall of the lower inner surface 2-6 of the housing is symmetrically provided with exhaust screw holes 2-6. 3 and the filler injection screw hole 2-4, the exhaust screw hole 2-3 is connected with the exhaust joint 8, the filler injection screw hole 2-4 is connected with the filler injection joint 7, and the filler 4 is injected into the filler cavity through the filler injection joint 7 , Then, the filling cavity between the inner core 3 and the outer shell 2 is evacuated thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com