Fast-assembly type water operation platform with lifting function

A work platform and quick-loading technology, which is applied in the form of bridges, transportation and packaging, floating buildings, etc., can solve the problems of lack of diving and lifting functions, small bearing capacity of floating box platforms, and short service life, etc., and achieve good results. Promotional value, good anti-wind and wave effect, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

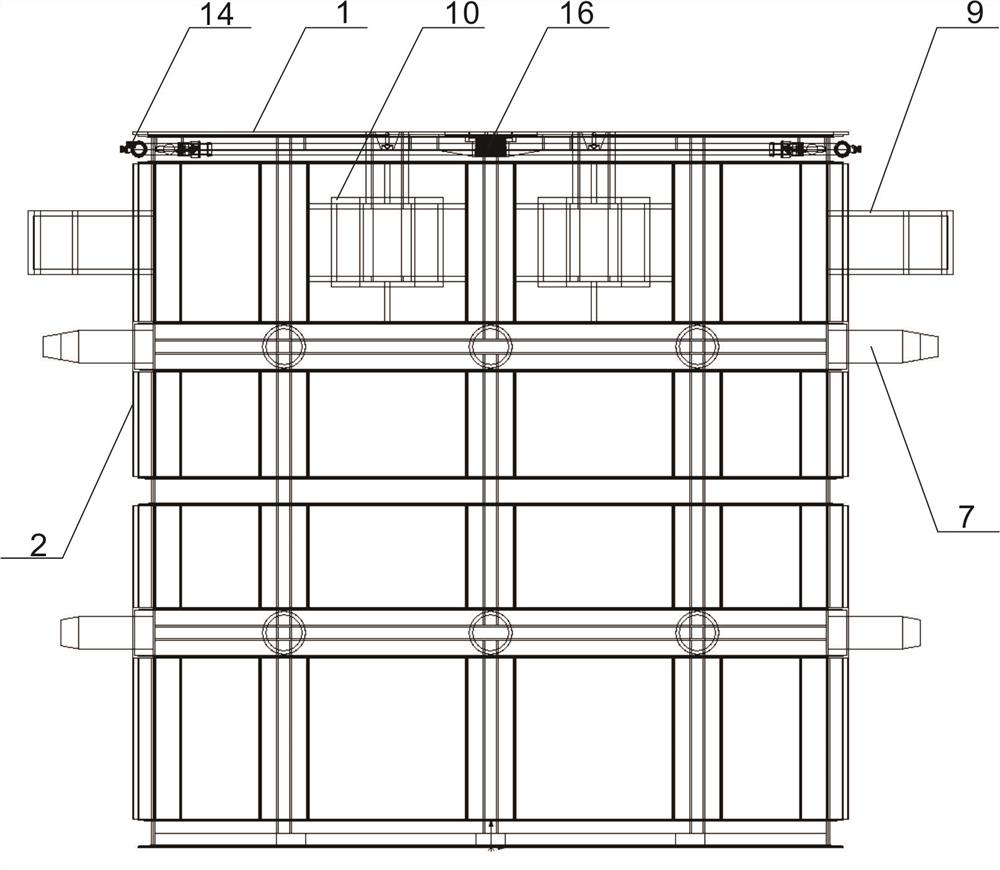

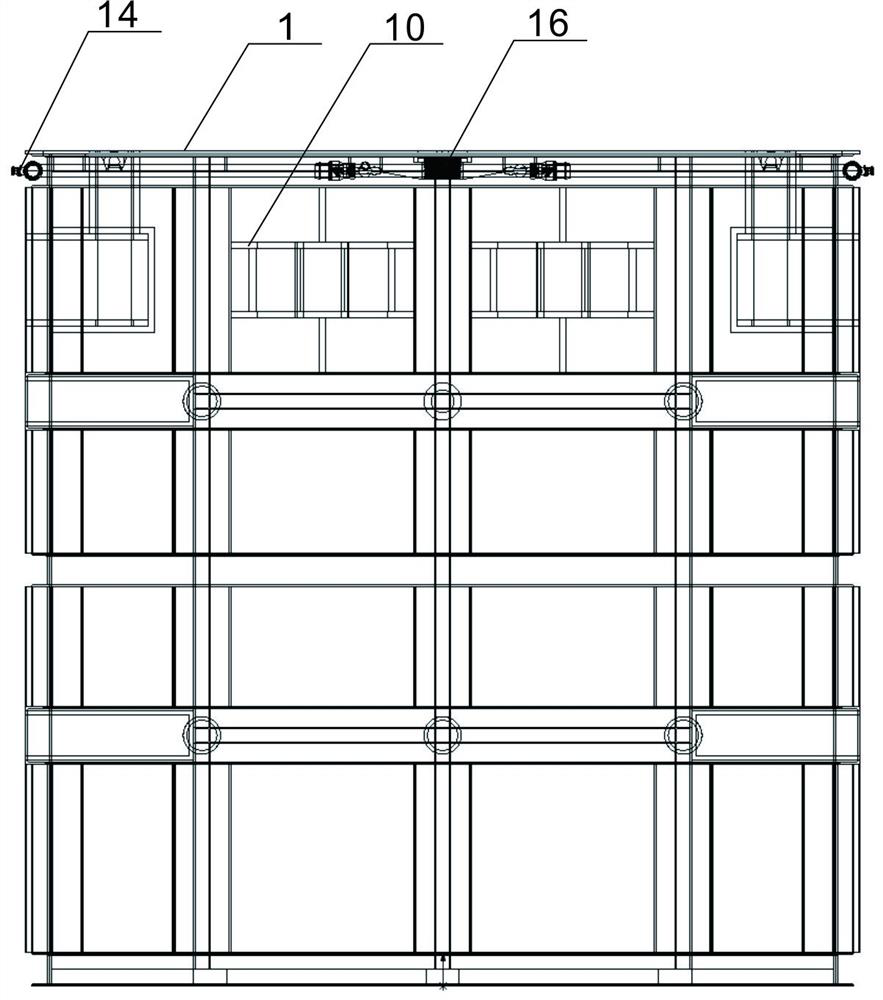

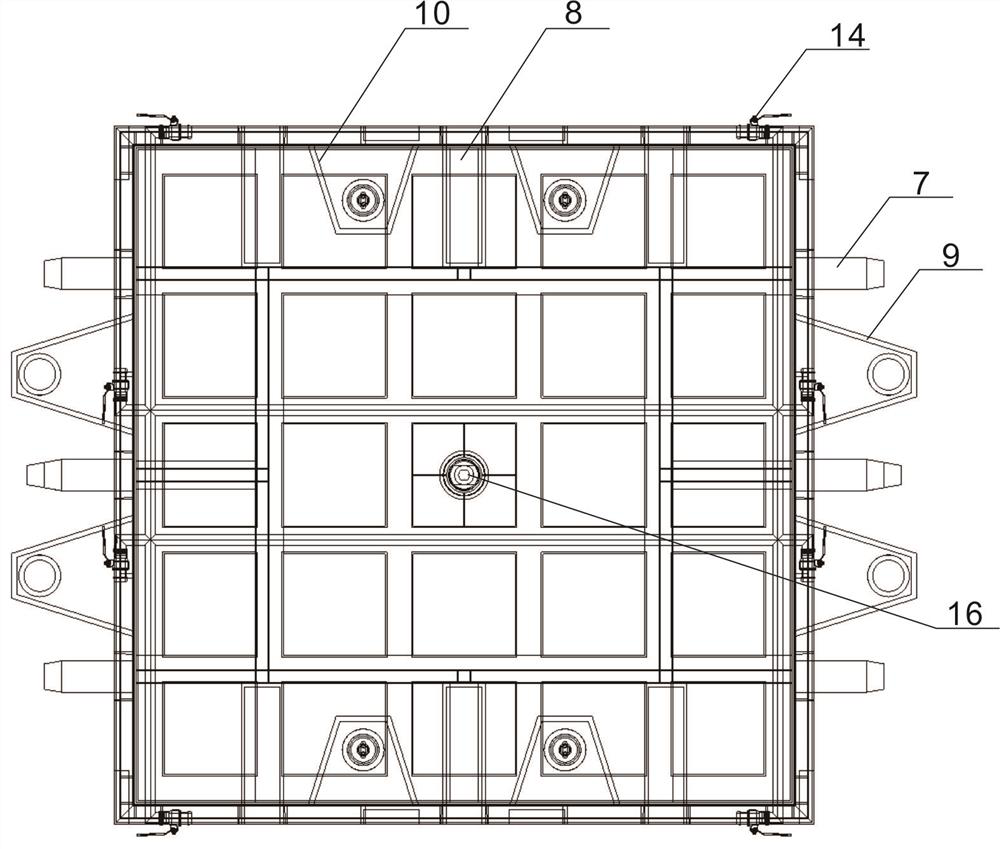

[0026] like Figure 1-10 As shown, the quick-installation water work platform with lifting function is assembled from several quick-installation platforms through connectors installed around the sides. The quick-installation platform mainly includes a support frame, a top panel 1, a side panel 2. Inflating and exhausting device, fixed buoyancy tank 18 and connectors, the support frame is a cube formed by welding several longitudinal main channel steels 5 and transverse main channel steels 3 which are located on the top and surrounding sides and distributed in a criss-cross pattern Frame; the top panel 1 is installed on the top, the side panel 2 is installed on the surrounding sides, the bottom is open, and the support frame is provided with a bearing frame 20 welded by vertically and horizontally staggered square stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com