Automatic iron cannon string sorting device

A sorting device and iron cannon technology, applied in packaging and other directions, can solve the problems of manual sorting and no automation, and achieve the effect of adjustable inclination and high sorting success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

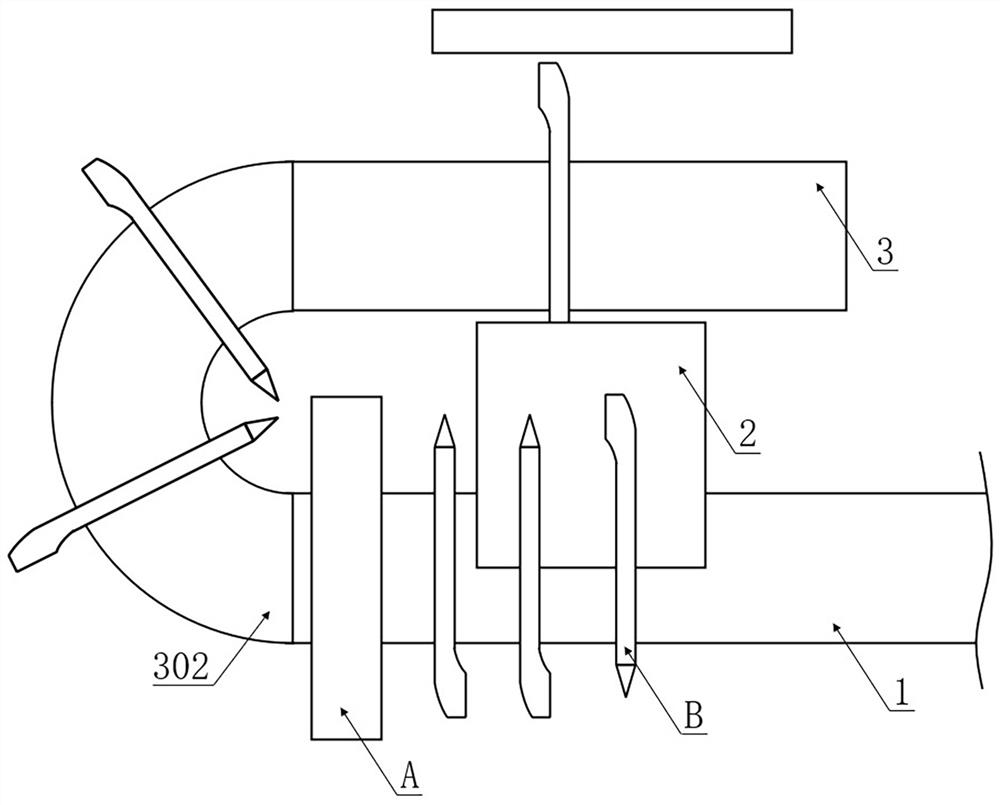

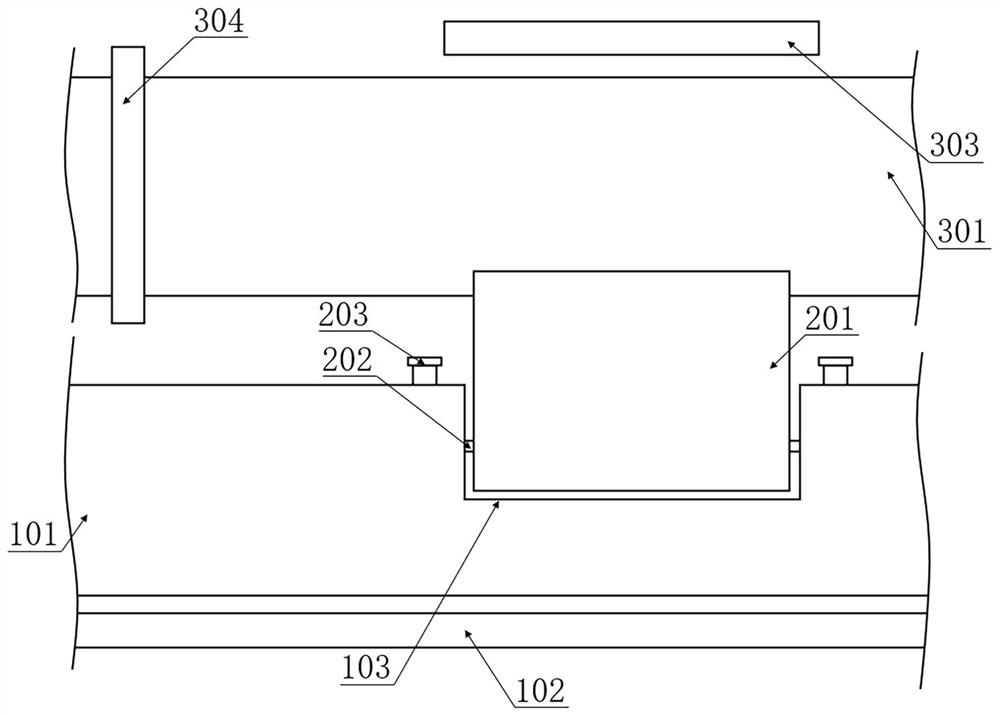

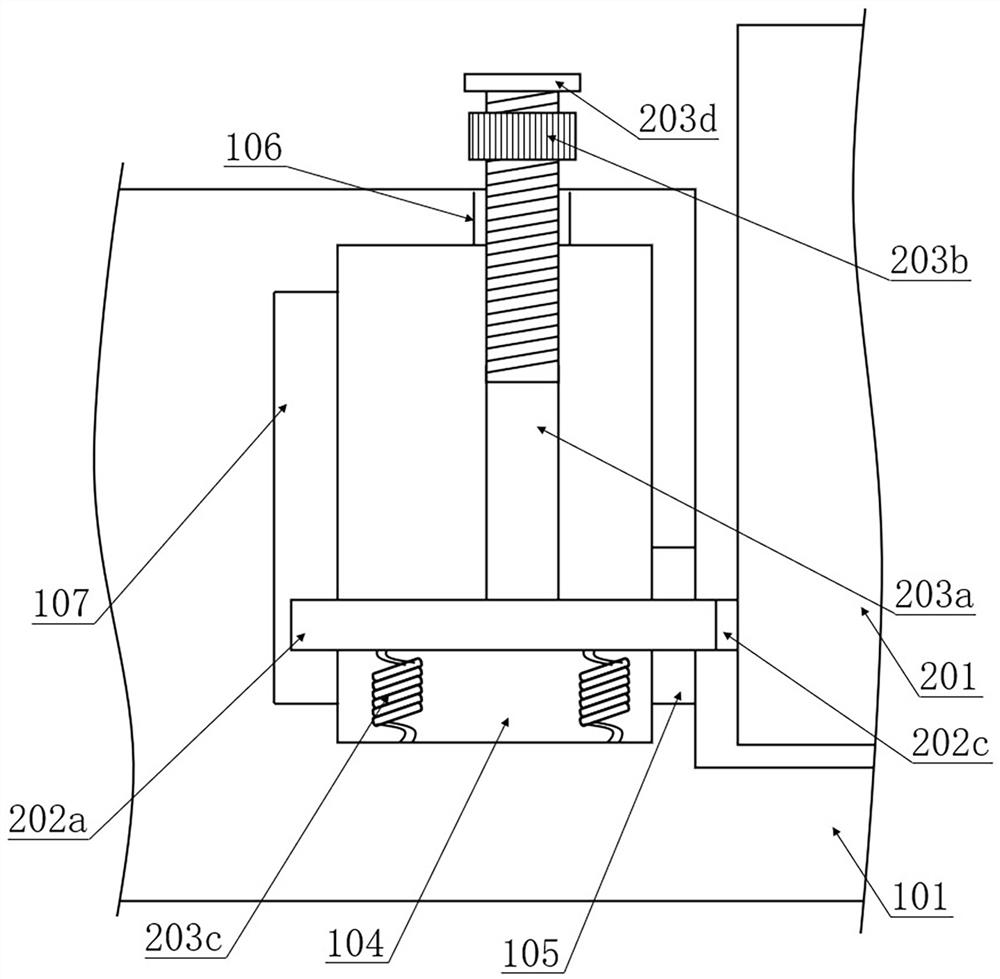

[0023] Example: as attached figure 1 , 2 , 3, 4 and attached Figure 5 As shown, an automatic iron gun string sorting device includes a transfer plate unit 1 arranged under the feeding pipe A and used to accept and transport the iron gun string B, which is arranged on the transfer plate unit 1 and utilizes the iron gun string B The slant plate unit 2 for sorting by center of gravity difference, and the return belt unit 3 arranged under the slant plate unit 2 and used to receive and transport the iron cannon string B back to the conveying plate unit 1 .

[0024] In this embodiment, as attached figure 1 As shown, the iron cannon string B falls from the feeding pipe A onto the conveying plate unit 1, and the conveying plate unit 1 drives the iron cannon string B to move to the right. The handle end of the iron cannon string B faces downward, and its center of gravity can be Always kept on the conveying plate unit 1, it can be transported by the conveying plate unit 1 to the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com