Automatic workpiece clamping device for industrial machining

A workpiece and industrial technology, applied in the field of automatic workpiece clamping devices for industrial processing, can solve the problems of unadjustable clamping range and low practicability of mechanical claw, achieve flexible and adjustable clamping range, protect workpiece, and avoid falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

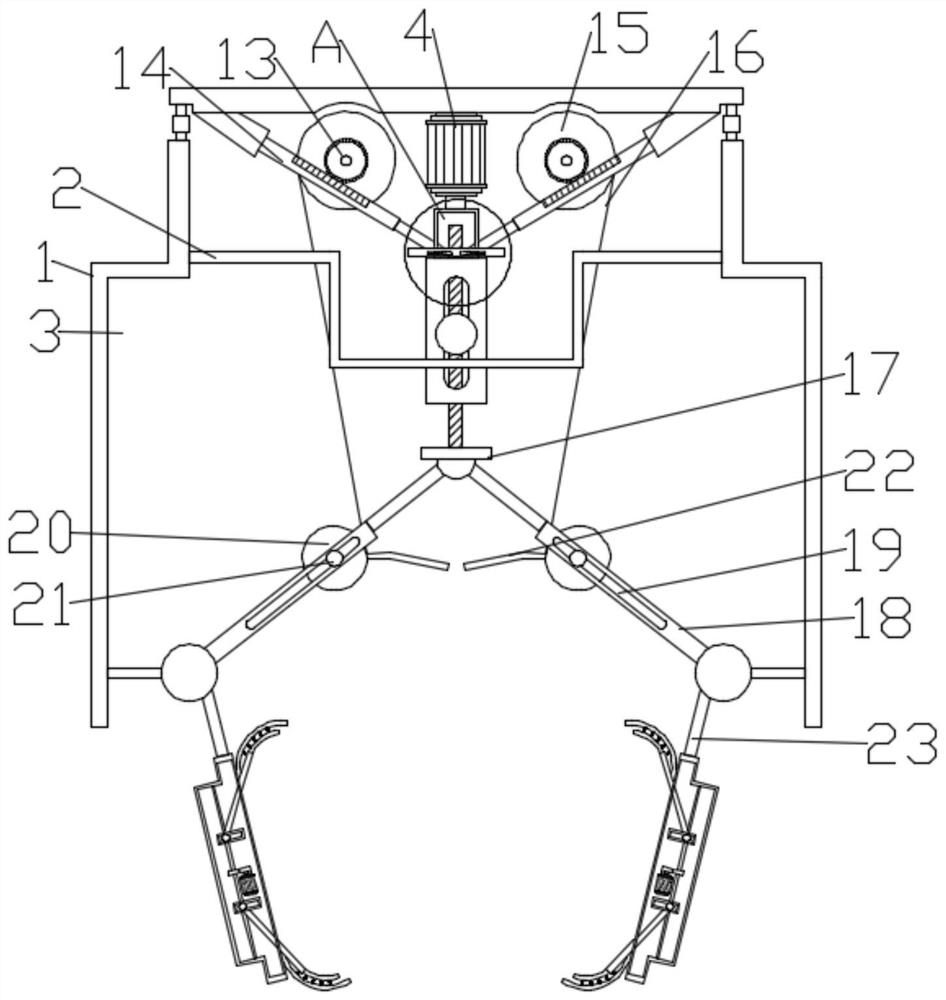

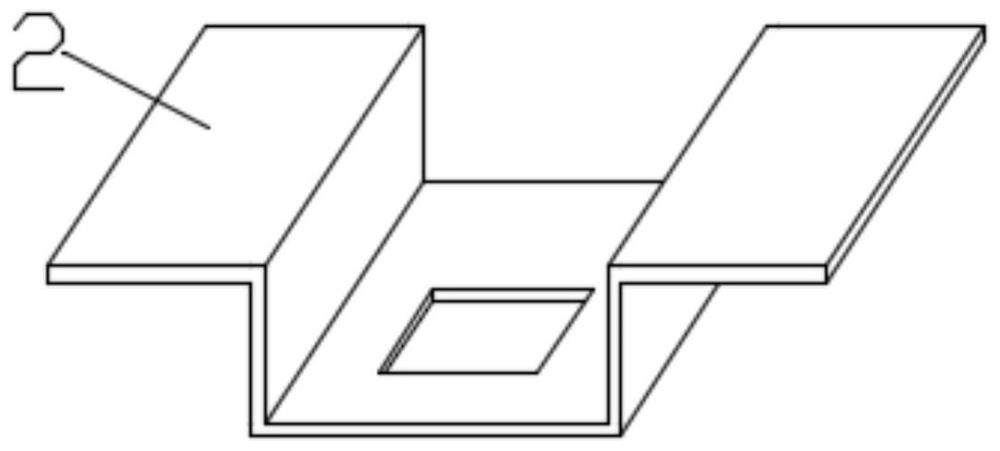

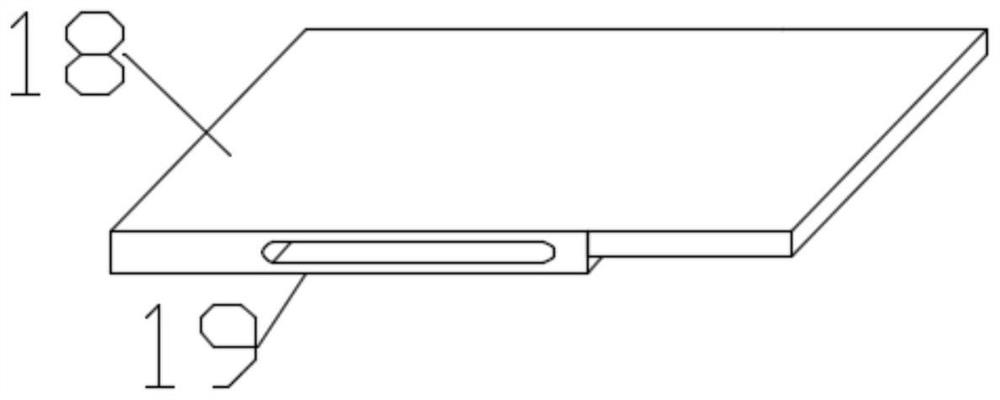

[0024] Such as Figure 1-2 As shown, in the embodiment of the present invention, an automatic workpiece clamping device for industrial processing includes a housing 1, a working chamber 3 is arranged in the housing 1, a positioning seat 2 is arranged in the middle of the working chamber 3, and a positioning seat 2 is arranged in the middle of the working chamber 3. The top is provided with a driving assembly, the driving assembly is connected with an auxiliary assembly, and the auxiliary assembly is connected with a clamping assembly 23;

[0025] The drive assembly includes a first working motor 4 and an internally threaded sleeve 5, the first working motor 4 is fixedly mounted on the top of the housing 1, and the output end of the first working motor 4 is fixedly connected with the internally threaded sleeve 5, and the internally threaded sleeve The barrel 5 is sleeved on the outside of the first screw 6, and the internally threaded sleeve 5 and the first screw 6 are threaded...

Embodiment 2

[0032] Such as Figure 1-2 As shown, in the embodiment of the present invention, an automatic workpiece clamping device for industrial processing includes a housing 1, a working chamber 3 is arranged in the housing 1, a positioning seat 2 is arranged in the middle of the working chamber 3, and a positioning seat 2 is arranged in the middle of the working chamber 3. The top is provided with a driving assembly, the driving assembly is connected with an auxiliary assembly, and the auxiliary assembly is connected with a clamping assembly 23;

[0033]The drive assembly includes a first working motor 4 and an internally threaded sleeve 5, the first working motor 4 is fixedly mounted on the top of the housing 1, and the output end of the first working motor 4 is fixedly connected with the internally threaded sleeve 5, and the internally threaded sleeve The barrel 5 is sleeved on the outside of the first screw 6, and the internally threaded sleeve 5 and the first screw 6 are threadedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com