Automatic assembling and welding device and method for pressure container

An automatic technology for pressure vessels, applied in the field of automatic assembly and welding devices for pressure vessels, can solve problems such as unsatisfactory back protection effect, inconvenient personnel access, long welding time for circular seams, etc., to enhance the protection effect, reduce work intensity, The effect of reducing personal safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

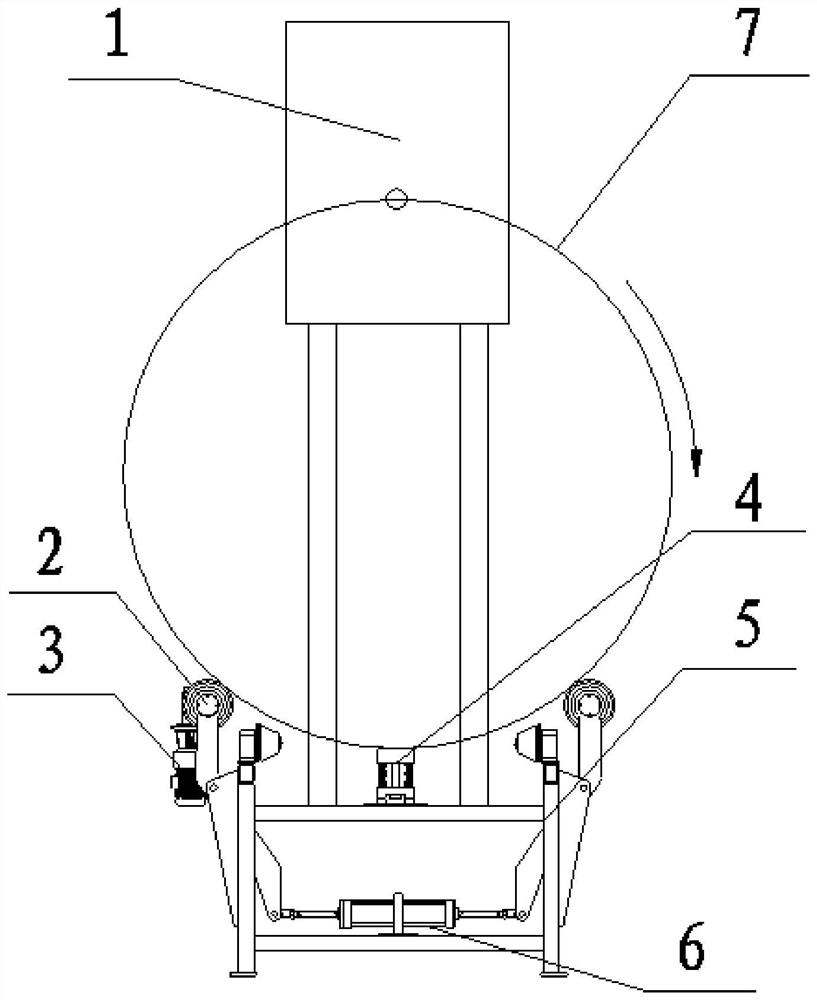

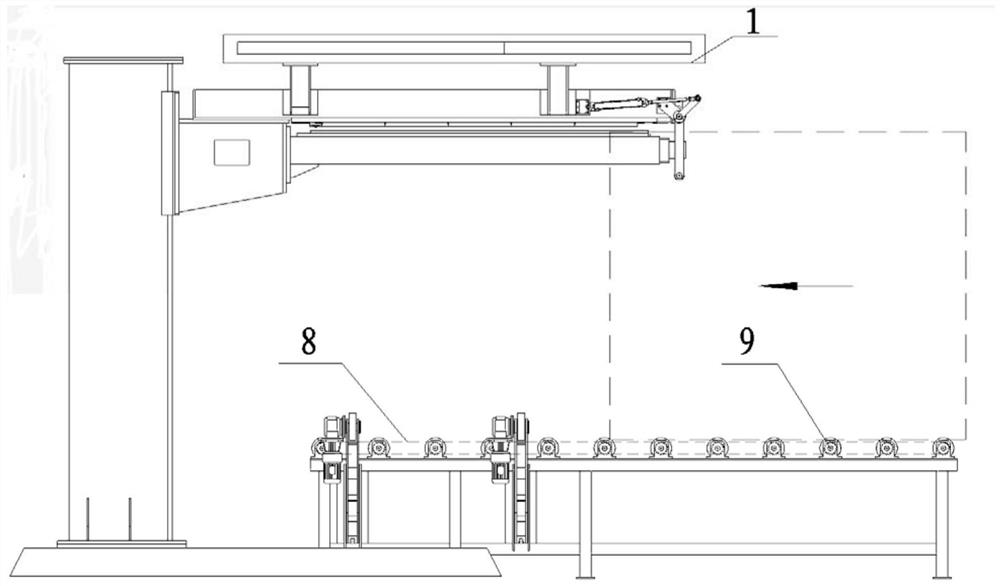

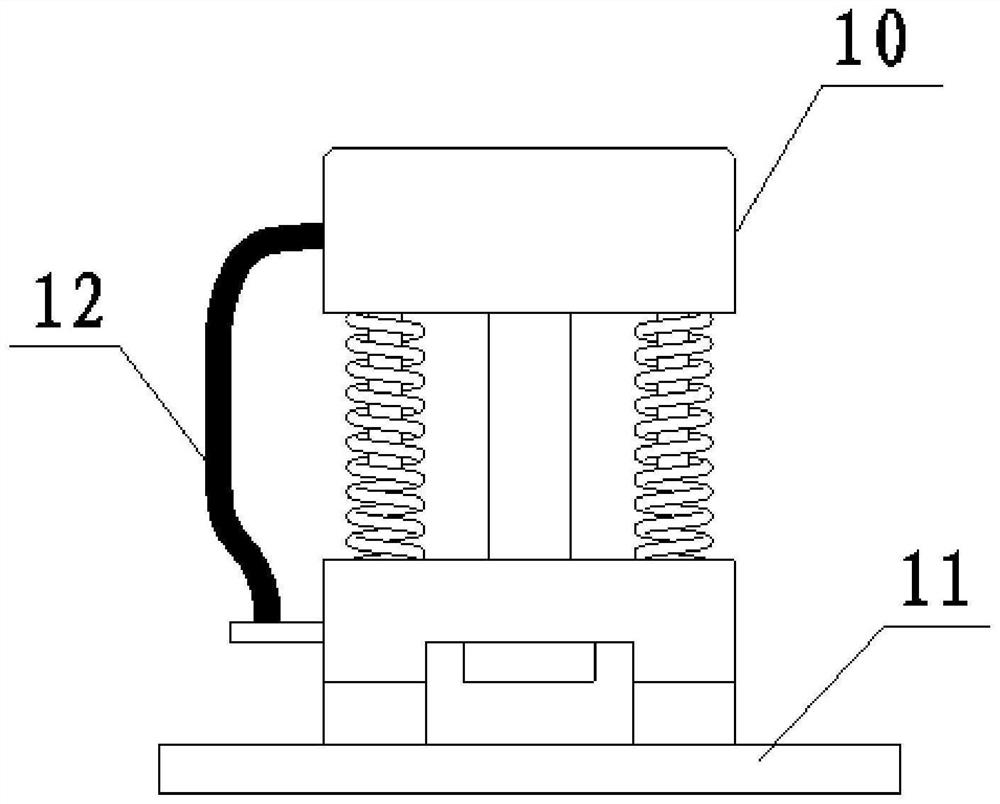

[0033] refer to Figure 1 to Figure 6 , an automatic assembly welding device for a pressure vessel, including a special welding machine and a longitudinal conveying mechanism for a barrel section, including a lifting mechanism for lifting the barrel section away from the longitudinal conveying mechanism for the barrel section, an automatic grounding device, an inner rounding device, and a rear protection for the welding ring seam of the barrel section device;

[0034] In the middle of the longitudinal conveying mechanism of the cylinder section, there is a welding station for butt welding of two cylinder sections. The welding machine is set above the welding station. The lifting mechanism is arranged on both sides of the welding station. Circumferentially rotating transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com