Diffuser with rectifying plate and application thereof

A diffuser and rectifying plate technology, which is applied in the field of diffusers with rectifying plates, can solve the problems of air flow that cannot be distributed and increased, and achieve the effect of reducing internal pressure loss and improving the recovery of static pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

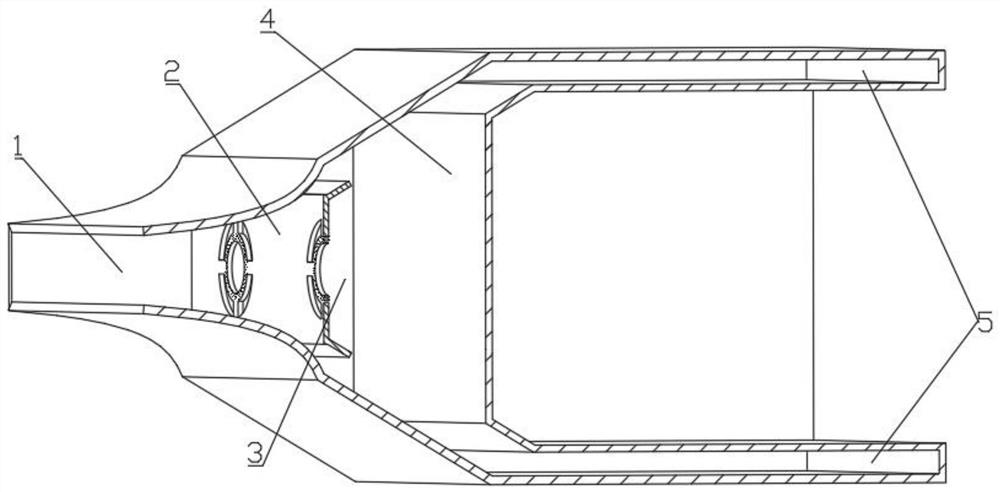

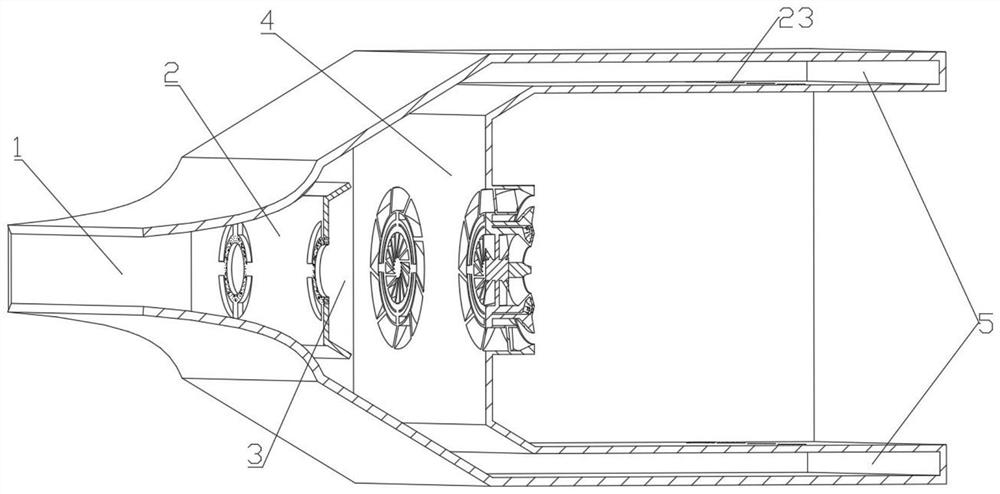

[0034] like figure 1 As shown, the present invention provides a diffuser structure with a rectifying plate, including a pre-diffuser 1 , a rectifying plate 2 , a sudden diffuser section 3 , a flame tube 4 and an inner and outer annular cavity 5 . The air flow flows out of the compressor and first flows into the pre-diffuser 1, then flows through the rectifying plate 2 and enters the sudden expansion diffuser section 3, and then flows into the flame tube to participate in combustion, cooling and mixing.

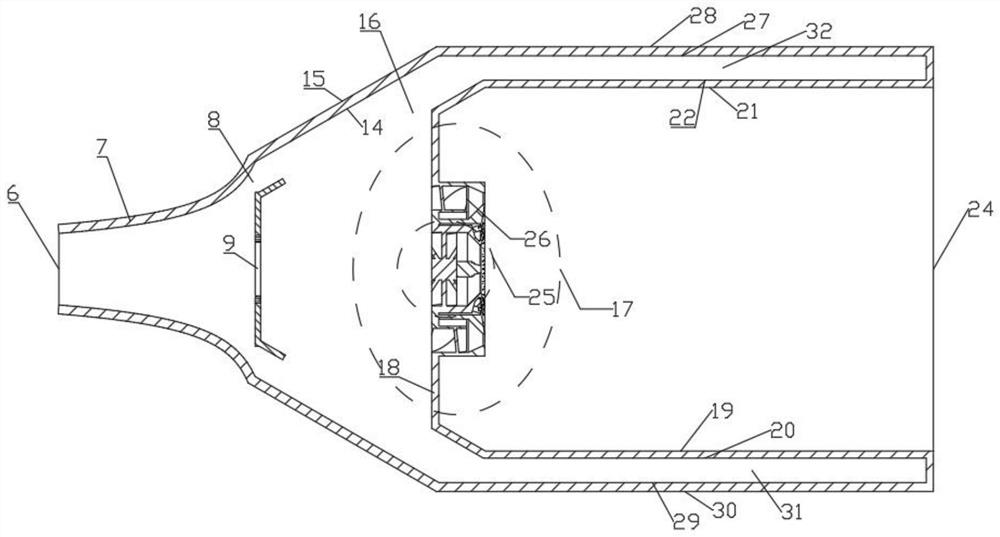

[0035] like figure 2 As shown, the prediffuser 1 is composed of a diffuser inlet 6 , a prediffuser wall 7 and a prediffuser outlet 8 . The airflow flows along the wall 7 designed based on the equal pressure gradient surface, and the flow near the wall does not separate. The airflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com