A high power converter

A converter, high-power technology, applied in the field of high-power semiconductor devices, can solve the problems of affecting deployment, damage to the windshield, unable to maintain a parallel state, etc., to achieve the effect of strengthening the connection relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

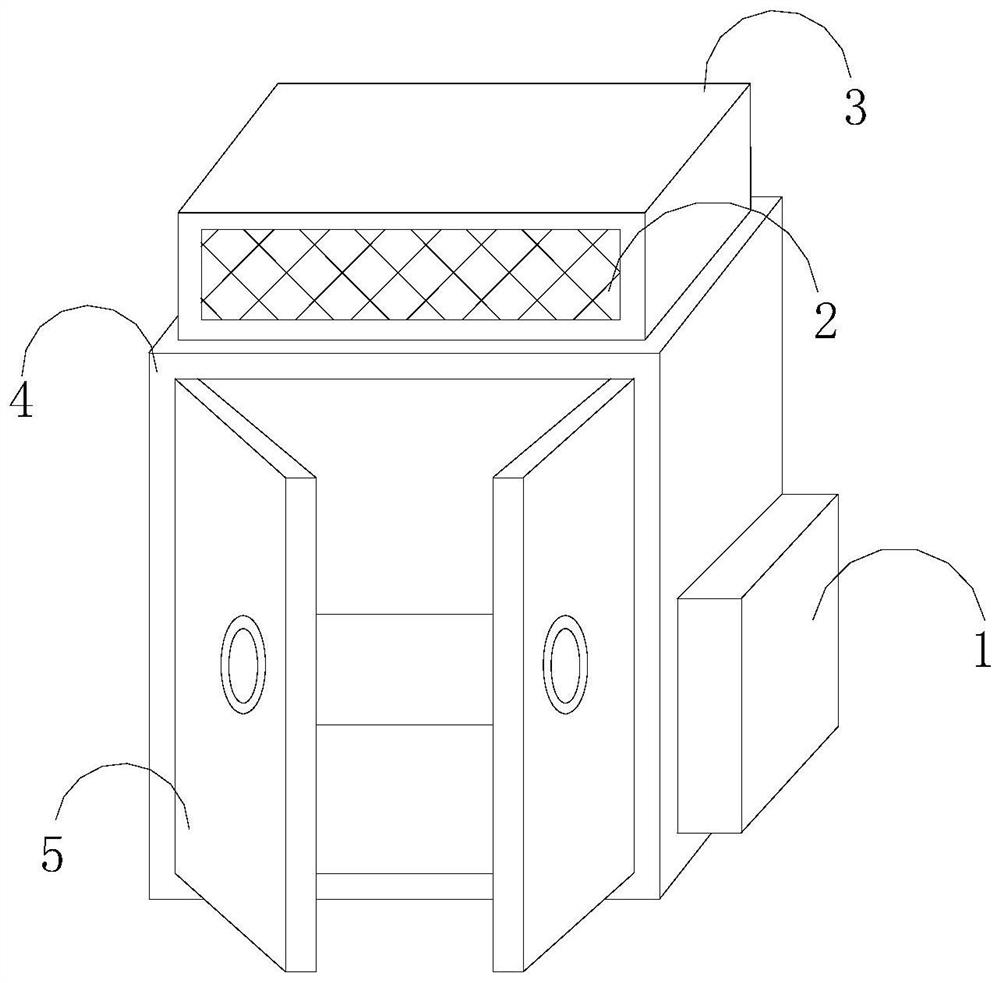

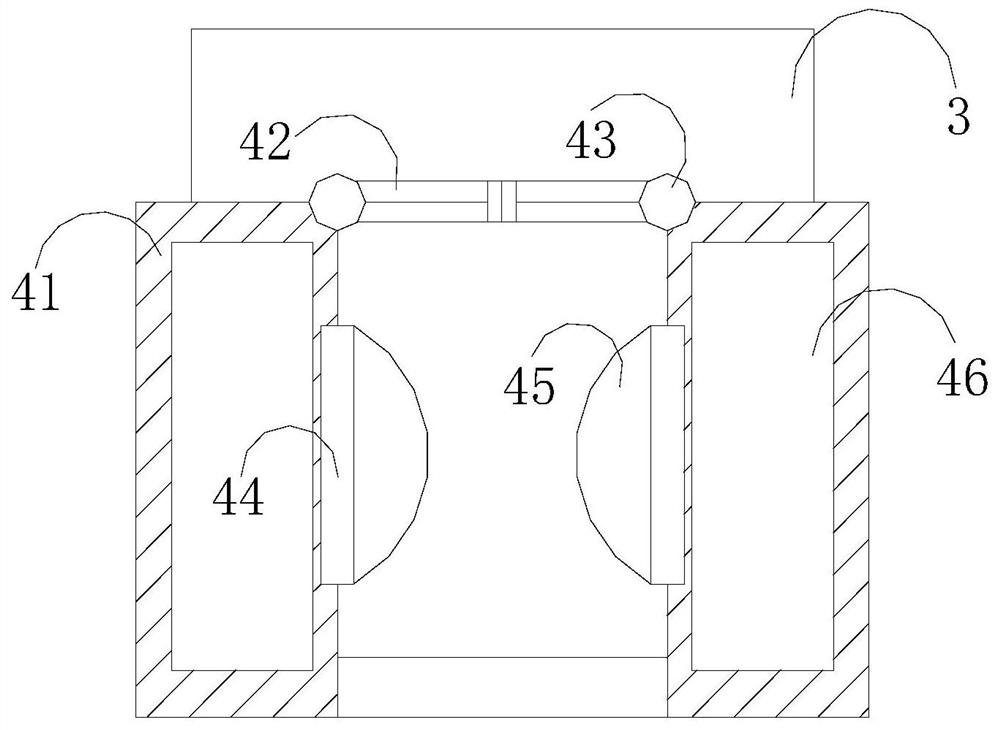

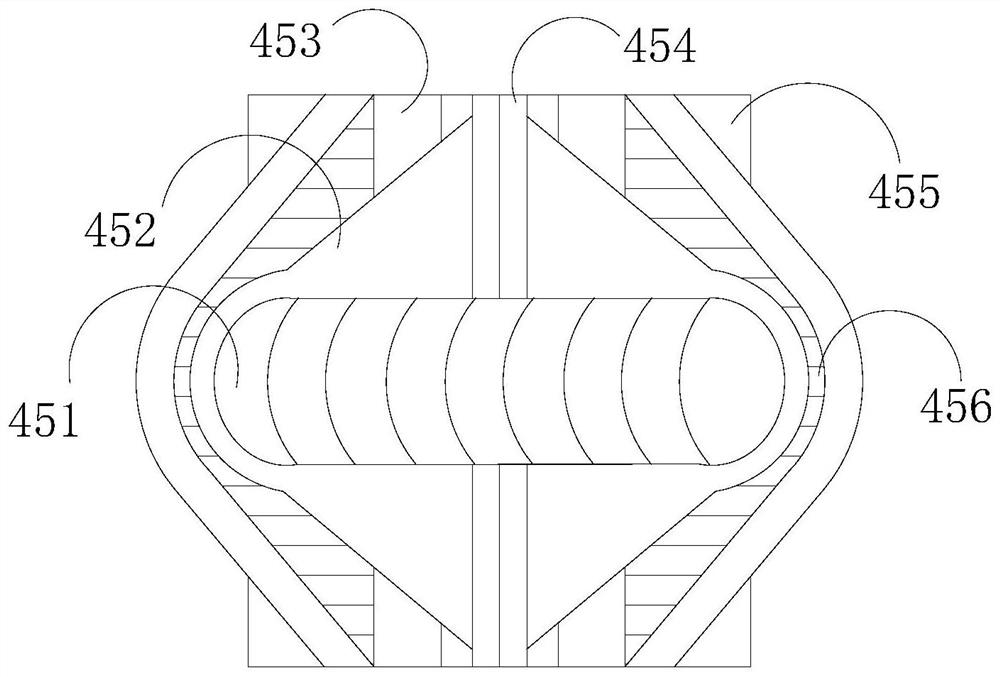

[0027] Such as Figure 1-Figure 3 As shown, the present invention provides a high-power converter, the structure of which includes a motor 1, a heat dissipation net 2, a conversion box 3, a host 4, and a cabinet door 5, and the motor 1 and the host 4 are electrically connected In cooperation, the main unit 4 is hingedly connected with a cabinet door 5, and the top is fixedly connected with a conversion box 3, and one side of the conversion box 3 is welded and connected with a cooling net 2, and the main unit 4 includes a cabinet body 41, a windshield 42. Rotating shaft 43, base pad 44, booster ball 45, and air duct 46. A windshield 42 is hingedly connected between the cabinet body 41 and the conversion box 3 through a rotating shaft 43, and an air duct 46 is fixedly connected inside it. One side of the air duct 46 is welded with a base pad 44, and the base pad 44 is provided with a booster ball 45, and the booster ball 45 includes a stacking cylinder 451, a side pressure devic...

Embodiment 2

[0029] Such as Figure 4-Figure 7 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The lateral pressure device 452 includes a crossover clip 2a1, a sliding brace handle 2a2, a spacer pocket 2a3, a drive chamber 2a4, and a bracket 2a5. The ferry clamp 2a1 is buckled and connected to the bottom of the driving chamber 2a4, which is a hollow structure, hingedly connected to the fixed frame 454 through the bracket 2a5, and the top is provided with a sliding brace handle 2a2 and a spacer pocket 2a3, the sliding brace The handlebar 2a2 includes a running-in belt a21, a paddle a22, a sloping plate a23, a connecting rod a24, and a retainer a25. The running-in belt a21 and the paddle a22 are equidistantly distributed on the outer circumference of the sloping plate a23, and between the sloping plates a23 A connecting rod a24 is fixedly connected, and one end of the connecting rod a24 is welded and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com