Arc-shaped bottom plate drop sill underflow stilling pool

A technology of arc-shaped bottom plate and stilling pool, which is applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of large amount of concrete, large elevation difference, and limited layout width of flood discharge buildings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

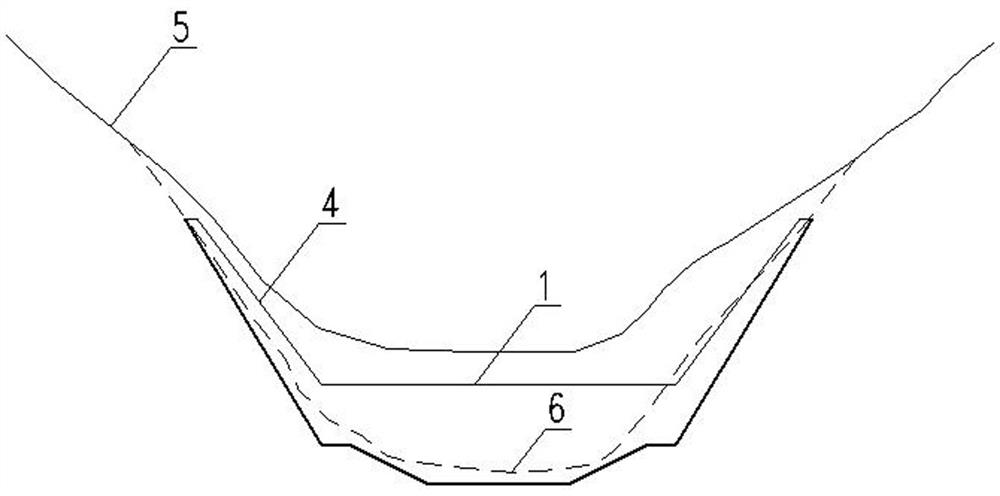

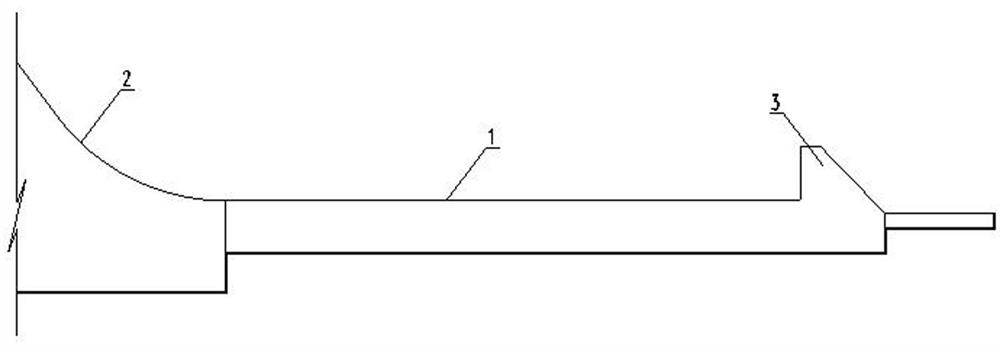

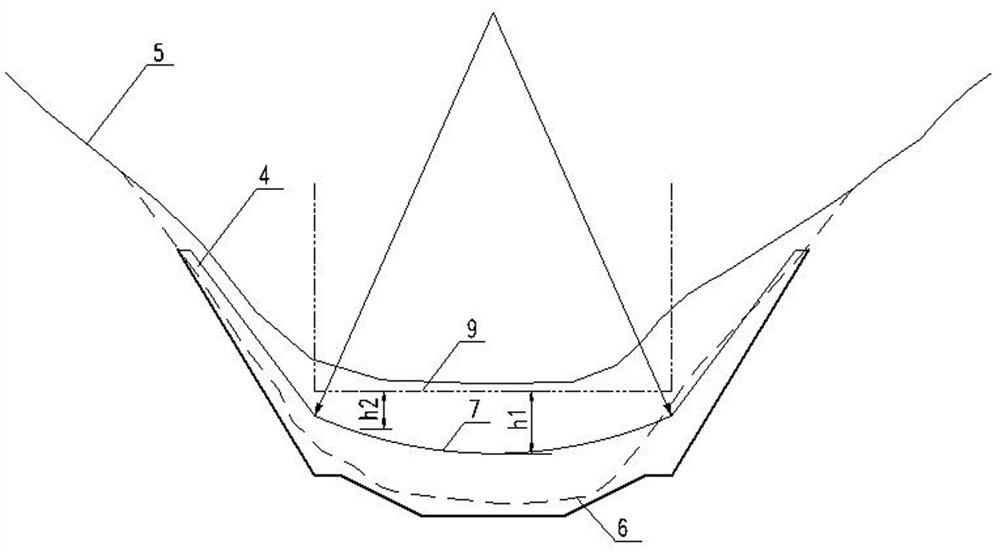

[0024] The bottom plate of the stilling pool in Embodiment 1 is an arc-shaped bottom plate stilling pool 7, and the cross-section of the top surface of the bottom plate perpendicular to the direction of water flow adopts an arc curve, thereby forming an arc-shaped bottom plate falling sill stilling pool. In this example, a 1:60 scale flat-bottom stilling pool of a project is used (such as Image 6 , Figure 7 ) and curved bottom sill stilling basin (such as Figure 8 , Figure 9 ) hydraulic model test has verified the effectiveness of the present embodiment.

[0025] A project is a second-class (2) type project, using a concrete gravity dam, the maximum dam height is 123m, and the flood discharge of the checked flood (P=0.05%) entering the reservoir is 10600m 3 / s, design flood (P=0.2%) inflow flood discharge 9410m 3 / s, energy dissipation design (P=2%) flood flow into storage is 7380m 3 / s. The valley at the dam site is narrow and basically symmetrical "V" shaped canyon...

Embodiment 2

[0034] Compared with Embodiment 1, the cross-section of the top surface of the stilling basin floor perpendicular to the water flow direction of the arc-shaped bottom plate falling sill stilling basin of this example adopts an elliptic curve.

Embodiment 3

[0036] Compared with Example 1, as Figure 10 As shown, the top surface of the bottom plate of the stilling pool with arc-shaped floor and falling sill in this example adopts a curve composed of a circular arc and a straight line. Use flat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com