Device and method for controlling bottle toppling in snakelike mesh belt conveying process

A technology of conveying process and serpentine net, which is applied in transportation and packaging, packaging automatic control, packaging, etc., and can solve the problems of small size unstable bottle shape and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

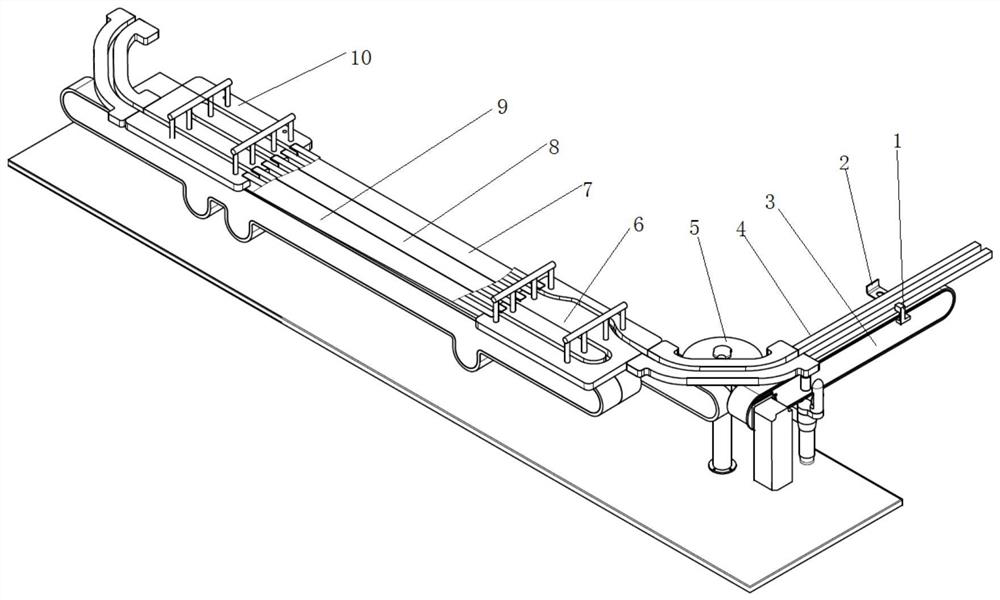

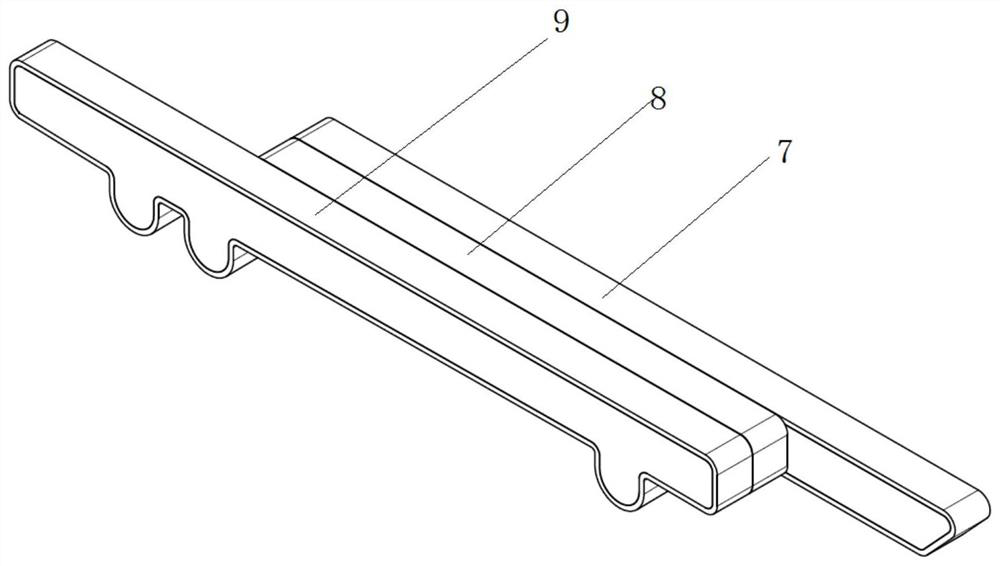

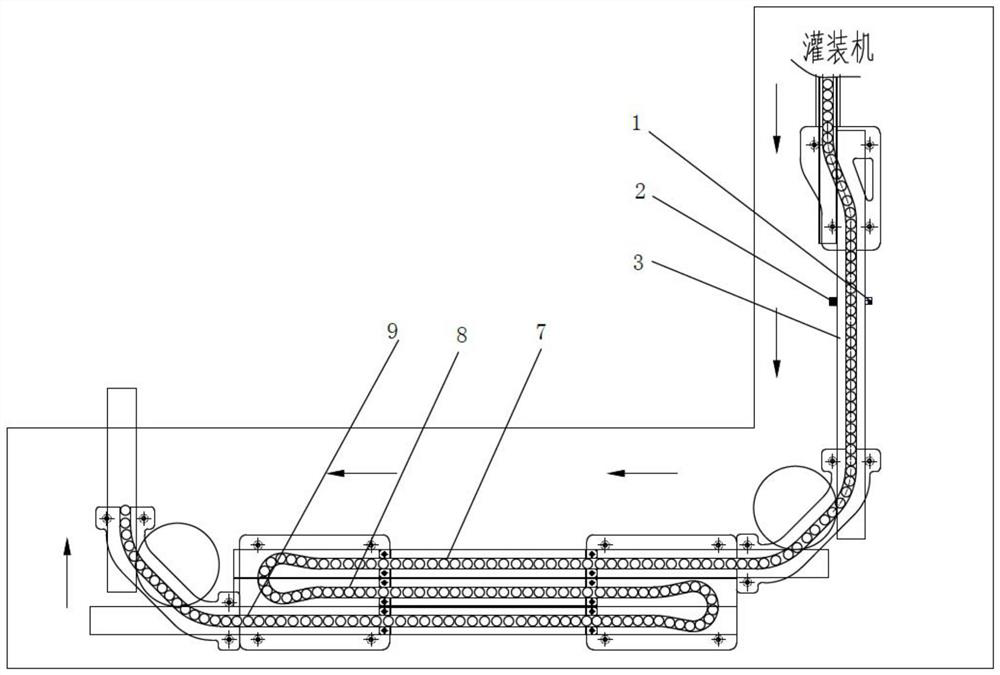

[0033] Such as Figure 1-7 As shown, the present invention provides a device for controlling bottle inversion during the conveying process of the serpentine mesh belt, which is arranged between the outlet of the filling machine and the inlet of the capping machine, and includes a docking mesh belt 3, a serpentine mesh belt, and a detection device and control system; the docking mesh belt 3 near the exit of the filling machine is connected with the serpentine mesh belt; the butt mesh belt 3 is provided with a detection device; the serpentine mesh belt is provided with a detection device; the detection device and the serpentine mesh belt are connected with the control system connection. The starting end of the serpentine mesh belt is provided with a detection device. The serpentine mesh belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com