Packaging machine clamping and sealing heating device

A heating device, packaging machine technology, applied in packaging sealing/tightening, packaging, transportation packaging and other directions, can solve the problems of difficult to guarantee movement accuracy and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

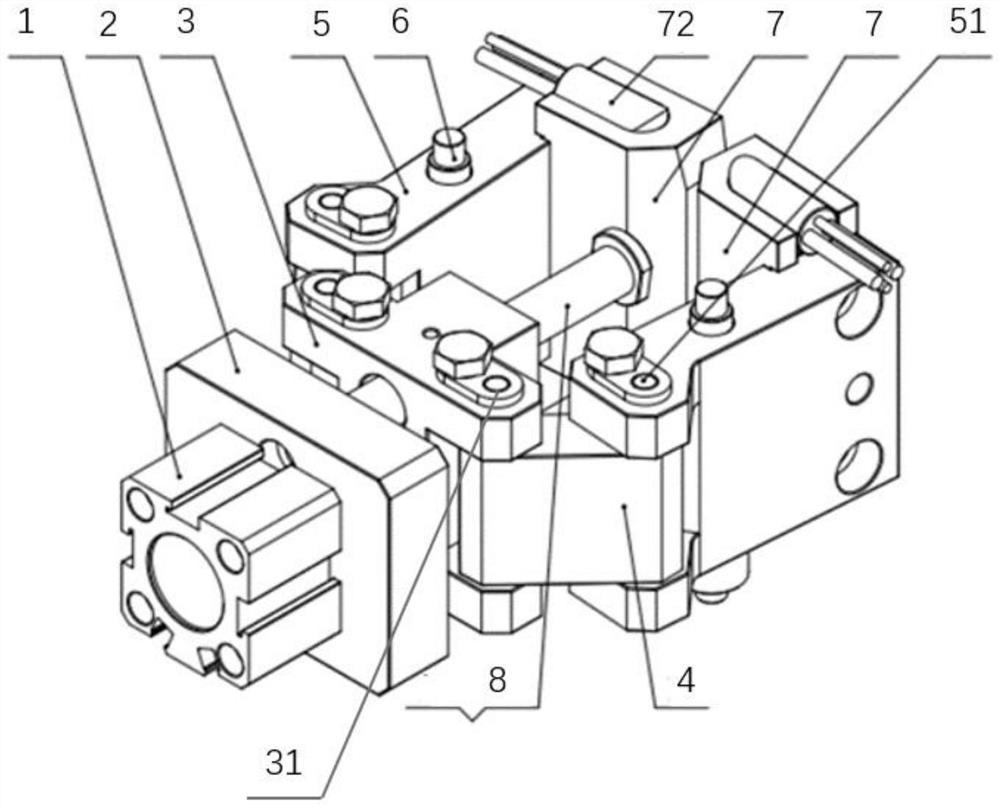

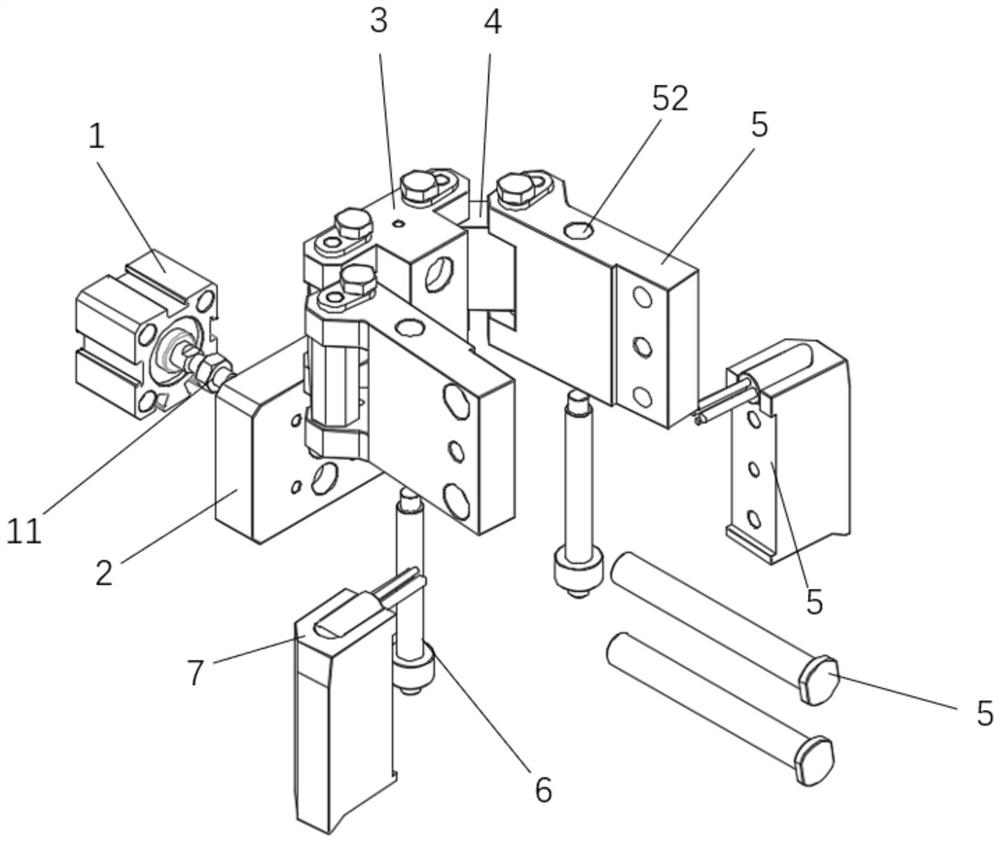

Embodiment 1

[0027] The invention provides a packaging machine clamp sealing heating device, such as Figure 1-2 As shown, it is mainly used in the heating link in the longitudinal sealing process of the vertical packaging machine, including the power cylinder 1, the fixed seat 2, the sliding seat 3, the hinge block 4, the rotating block 5, the fixed shaft 6 and the heating block 7. The power cylinder 1 can be a pneumatic power cylinder or a hydraulic power cylinder, which is provided with a transmission shaft 11, and the transmission shaft 11 can be stretched. The fixed base 2 is fixed on the frame or base of the packaging machine (not shown in the figure), and does not move relative to each other as a fixed part, and is preferably a square or circular disc-shaped structural block. The power cylinder 1 is connected to the side of the fixed seat 2, and its power transmission shaft 11 is connected with the sliding seat 3 after passing through the shaft hole provided on the fixed seat 2. Sl...

Embodiment 2

[0033] This embodiment 2 is formed on the basis of embodiment 1. Through the guide rod and the elastic member sleeved on the guide rod, the operation stability of the clamping heating device of the packaging machine is improved, and at the same time, excessive Heat radiation causes the laminated film to stick to the heating block. specifically:

[0034] Such as Figure 1-2As shown, a guide rod 8 is also provided in the clamping and heating device of the main packaging machine. Corresponding shaft holes are provided on the sliding seat 3, and one end of the guide rod 8 is fastened to the fixed seat 2. The connection method The other end of the guide rod 8 can pass through the shaft hole on the slider 3 and extend to a certain distance outside the slider 3 by means of screw connection or welding, and the guide rod 8 and the slider 3 are slidably connected, that is, the guide rod 8 can slide freely in the shaft hole of slide seat 3. After the guide rod 8 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com