A motor braking device

A brake device and linkage mechanism technology, applied in the direction of electromechanical devices, cooling/ventilation devices, mechanical equipment, etc., can solve the problems of brake pad temperature rise, installation and manufacturing errors, and affect the braking effect, so as to prevent movement and ensure Braking effect, the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

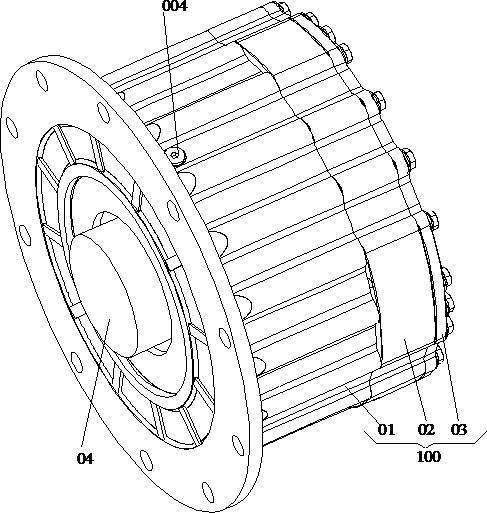

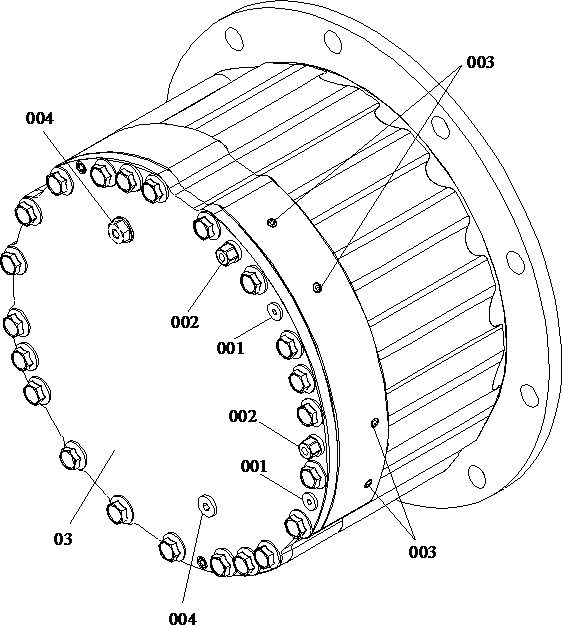

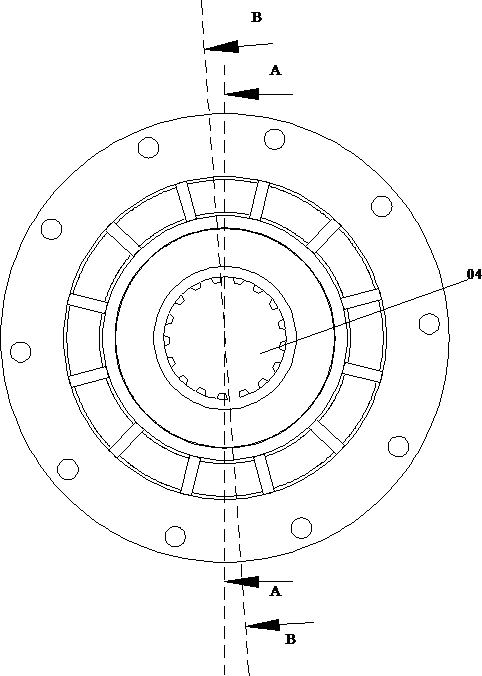

[0047] Example: such as Figure 1 to Figure 4 As shown, the present invention provides a motor braking device, which is used for braking the motor, that is, the motor includes a braking device and a motor body, wherein the rotating shaft of the motor needs to have an extension section 04, and extends into the braking device. The extension section 04 of the rotating shaft can be a part of the rotating shaft of the motor, or a section of shaft body coaxially connected with the rotating shaft of the motor; the braking device includes a base sleeve 100, and the extending section 04 of the rotating shaft of the motor extends to In the base sleeve 100; in order to facilitate assembly, the base sleeve 100 is a split structure, including the flange sleeve 01, the connection sleeve 02 and the end cover 03 arranged in sequence, and at the connection, the flange sleeve 01, the connection sleeve 02 and the end cover The covers 03 are sealed and connected, and the three are connected by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com