Pump head, pump core with pump head and palm pressure type building block pump tank with pump core

A pump head and pump core technology, which is applied to parts, pumps, piston pumps, etc. of pumping devices for elastic fluids, can solve problems such as slow extrusion speed, and achieve labor-saving operation and achieve the effect of diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is attached Figure 1-10 The application is described in further detail.

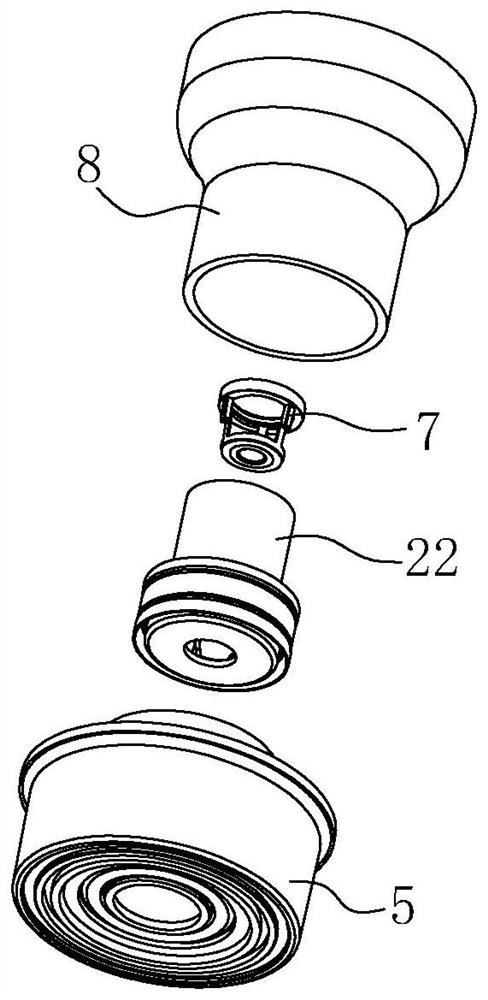

[0043] The embodiment of the present application discloses a pump head, such as figure 1As shown, it includes a pump casing 1 , a pump material assembly 2 inside the pump casing 1 , and a gland 3 that passes through the pump casing 1 and cooperates with the pump material assembly 2 . like figure 2 and image 3 As shown, the pump casing 1 is a cylindrical casing with one end open and the other end closed; the pump material assembly 2 is mainly composed of a partition support 5 and a piston body 22 located in the partition support 5 and slidingly fitted with the partition support 5. The separation support 5 includes an outer cylinder 51 and an inner cylinder 52 coaxially sleeved. The inner cylinder 52 and the outer cylinder 51 are connected to each other at one end, or both are integrally formed. In this embodiment of the application In , we define that the separation support 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com