A kind of automatic welding machine and using method thereof

A technology of automatic welding machine and welding torch, which is applied in the direction of welding accessories, welding rod characteristics, and devices supporting electrode clamps, etc. It can solve the problems of automatic solder replenishment, single welding method, and unstable welding contact points, etc., and achieves wide applicability. Ease of use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

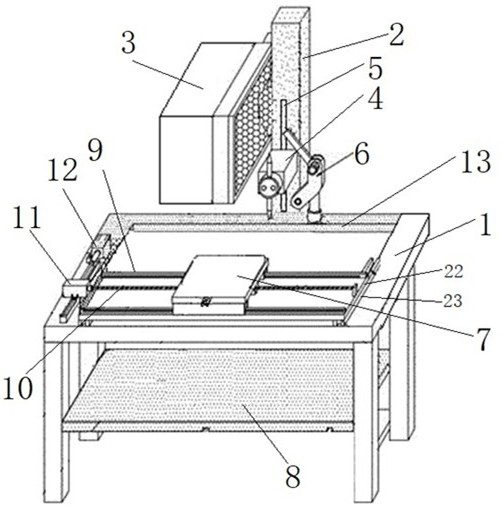

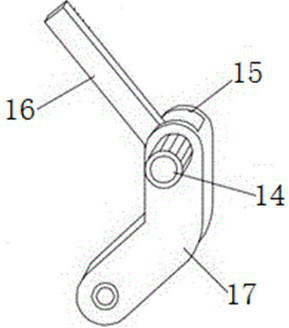

[0044] An automatic welding machine is composed of a welding station 1, a welding torch 4, a material supply box 3 and a torch pressing mechanism 6.

[0045] The middle part of the table top of the soldering station 1 is hollowed out, and the table top is ring-shaped; a pair of parallel first slide rails 9 are arranged horizontally and horizontally in the ring of the table top, and the two ends of the first slide rails are respectively (vertically) fixedly connected to the slide plate 22, the slide plate 22 slides along the second slide rail 23 arranged horizontally and longitudinally, and the second slide rail 23 is fixedly connected with the table top (or the ring side of the table top). The platen 7 is placed on the first slide rail 9 through the slideway on the bottom surface, and slides horizontally along the first slide rail 9; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com