Box opening and boxing integrated automatic production line and working method thereof

An automated production line and integrated technology, applied in packaging and other directions, can solve problems affecting normal use, wrong number of items, damaged packaging boxes, etc., to achieve the effects of convenient packing operations, improved packaging efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

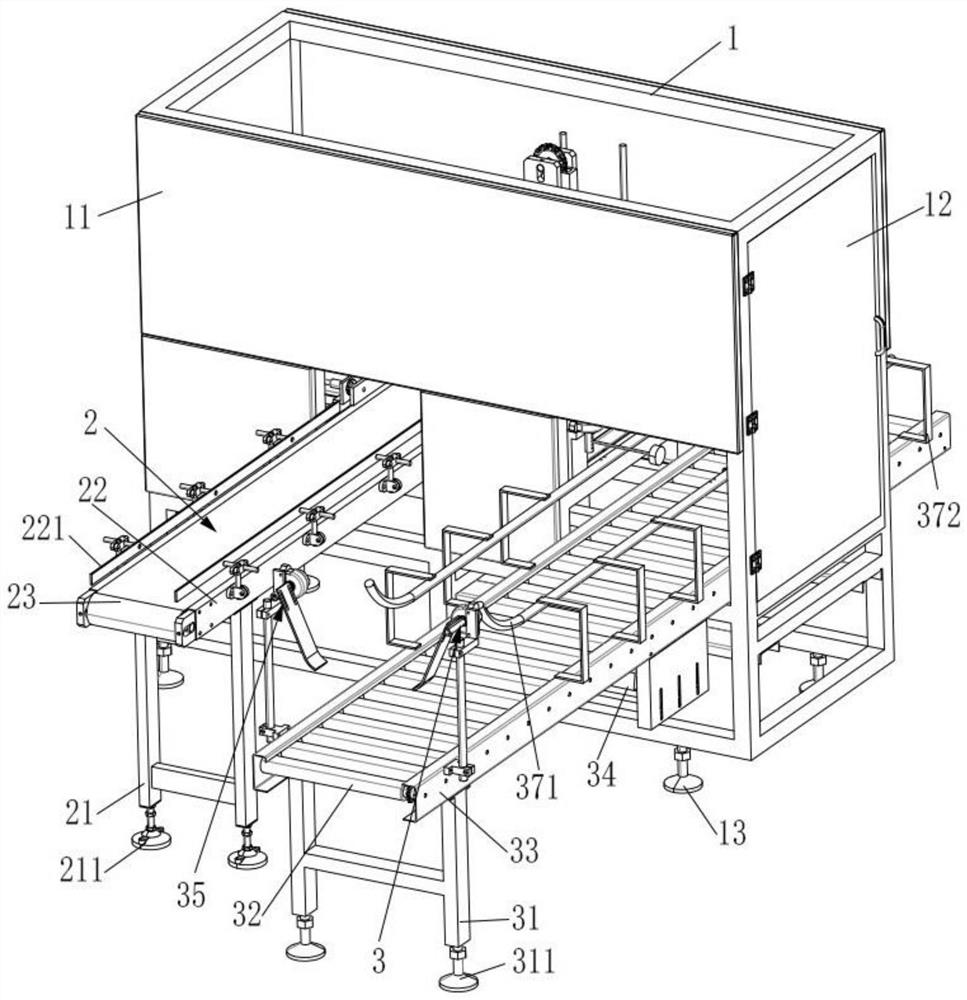

[0048] Such as Figure 1-3 As shown, an integrated automatic production line for box support and box packing, including a frame 1, a feeding part 2 for conveying products 6, a box supporting part 3 for opening the lid of a packing box 5, and a retrieving part 4, the feeding part 2 Partially set in the machine frame 1 through the second fixed beam 15, the said box supporting part 3 is partly set in the frame 1 through the third fixed beam 16, and the said retrieving part 4 is set in the machine frame through the first fixed beam 14 In the frame 1, a guide rail 141 is provided on the first fixed beam 14, and the retrieving part 4 is slidably connected with the guide rail 141. The feeding part 2 is arranged in parallel with the supporting part 3. The retrieving part 4 is arranged Above the feeding part 2 and the box supporting part 3.

[0049] Among them, such as Figure 4 As shown, the feeding part 2 includes a first fixed frame 21, a feeding table 22, a conveyor belt 23, a fi...

Embodiment 2

[0063] Such as Figure 1-3 As shown, an integrated automatic production line for box support and box packing, including a frame 1, a feeding part 2 for conveying products 6, a box supporting part 3 for opening the lid of a packing box 5, and a retrieving part 4, the feeding part 2 Partially set in the machine frame 1 through the second fixed beam 15, the said box supporting part 3 is partly set in the frame 1 through the third fixed beam 16, and the said retrieving part 4 is set in the machine frame through the first fixed beam 14 In the frame 1, a guide rail 141 is provided on the first fixed beam 14, and the retrieving part 4 is slidably connected with the guide rail 141. The feeding part 2 is arranged in parallel with the supporting part 3. The retrieving part 4 is arranged Above the feeding part 2 and the box supporting part 3.

[0064] Among them, such as Figure 4 As shown, the feeding part 2 includes a first fixed frame 21, a feeding table 22, a conveyor belt 23, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com