Hotpot condiment stir-frying method and equipment thereof

A technology for hot pot bottom material and frying material, which is applied to the field of hot pot bottom material frying method and equipment, can solve the problems of being easily limited by heat supply, high requirements for operators, small heating area of the frying pan, etc., and achieves economical frying time, improving production efficiency, and efficient frying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

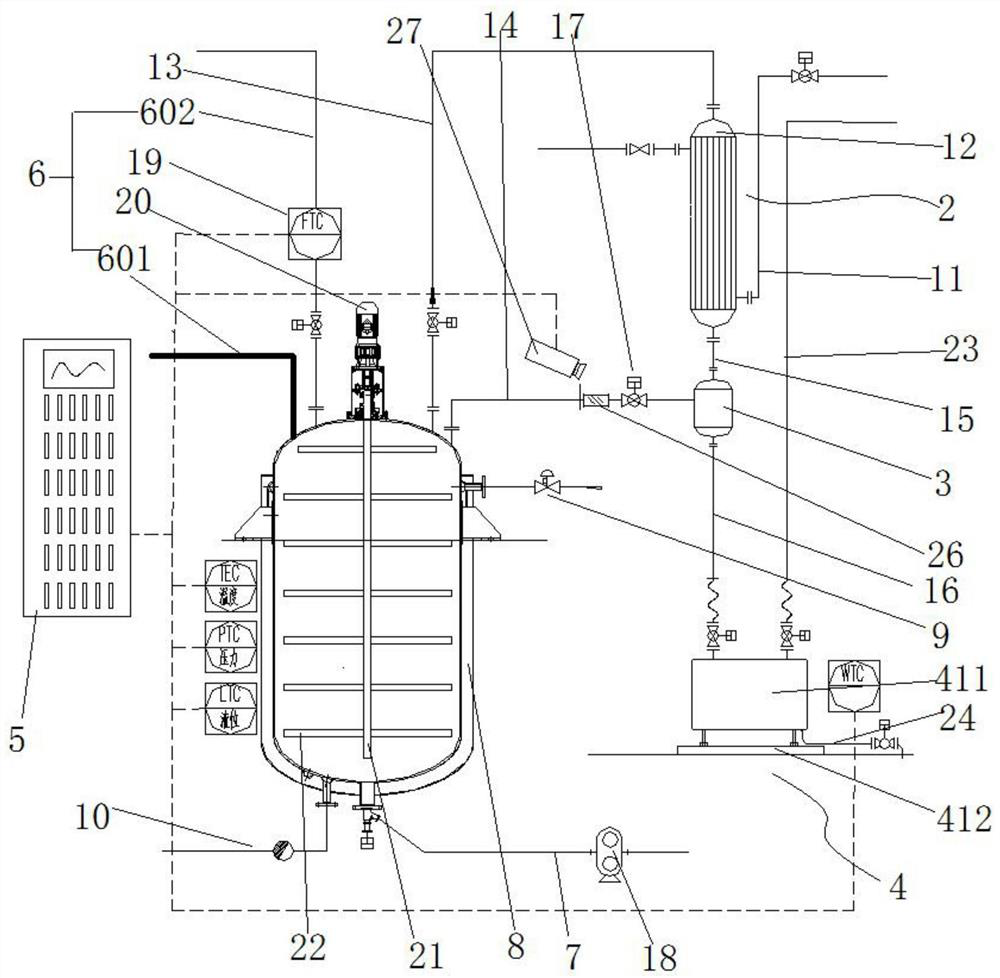

[0023] Specific embodiment one, such as figure 1 As shown, a method for frying hot pot bottom material and equipment thereof, comprising a reactor 1, a heat exchanger 2, an oil-water separation tank 3, a weighing water tank 4 and an electric control box 5, the top of the reactor 1 is provided with a stirring Mechanism and material inlet 6, the bottom of the reaction kettle 1 is provided with a material outlet 7, and the outer cover of the reaction kettle 1 is connected with a heating mantle 8, and the heating mantle 8 is provided with a steam inlet 9 and a condensed water outlet 10. The heat exchanger 2 includes a cooling water pipe 11 and a heat exchange cylinder 12, the upper end of the reaction kettle 1 and the upper end of the heat exchange cylinder 2 are communicated through a first pipe 13, and the upper end of the reaction kettle 1 and the upper end of the oil-water separation tank 3 are connected through a first pipe 13. Two pipelines communicate with 14, the lower end...

specific Embodiment 2

[0040] Specific embodiment 2, in S1, the material with clear water content and water are distributed according to the ratio of 17.5:1 and added into the reaction kettle through the liquid material inlet and the solid material inlet, and the temperature in S3 is raised from 90°C to 137.5°C and then kept for 45 Minutes, feed cooling water after 30 seconds in S4, other operating steps method and equipment are identical with specific embodiment one.

specific Embodiment 3

[0041] Specific embodiment three, in S1, the material with clear water content and water are distributed according to the ratio of 20:1 and added into the reaction kettle through the liquid material inlet and the solid material inlet, and the temperature in S3 is raised from 90°C to 150°C and then kept for 3 Minutes, feed into cooling water after 60 seconds in S4, other operating steps method and equipment are identical with specific embodiment one.

[0042] Working principle and flow process of the present invention:

[0043] In the present invention, materials and water are firstly added to the reaction kettle at one time, and then fried according to the above-mentioned steps. The DCS central control system and various sensors can make the frying of the hot pot bottom material easier. The high temperature and high pressure fry the material. The high temperature and high pressure frying method can improve the taste of the hot pot bottom material, use the evaporation of water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com