Automatic deep-frying device for deep-fried foods

A fried food, automatic technology, applied in the direction of oil/fat baking, etc., can solve the problems of immature frying, high labor cost, slow production speed of oil cakes, etc., to achieve a wide range of products, large market demand, and favorable The effect of market competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

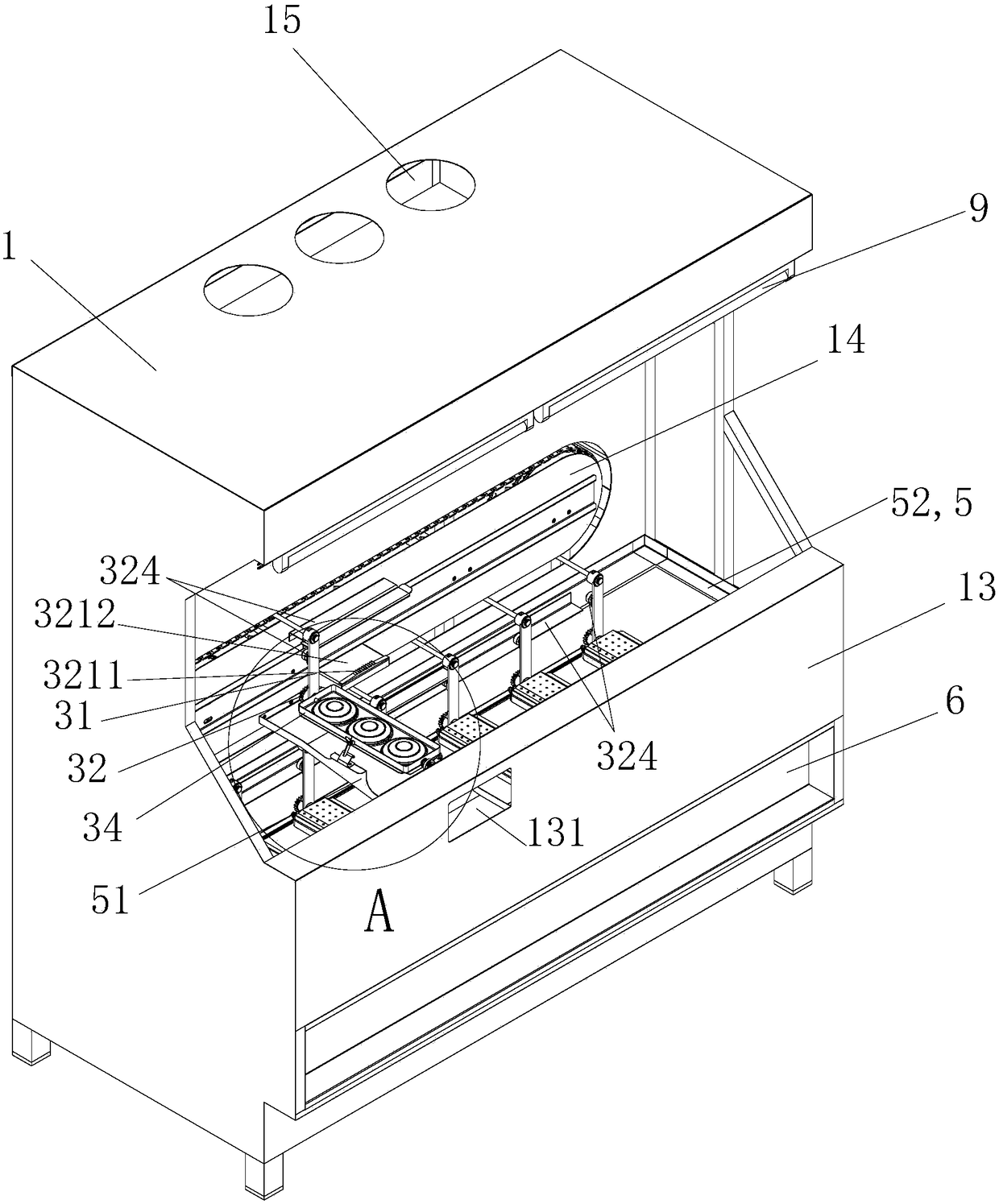

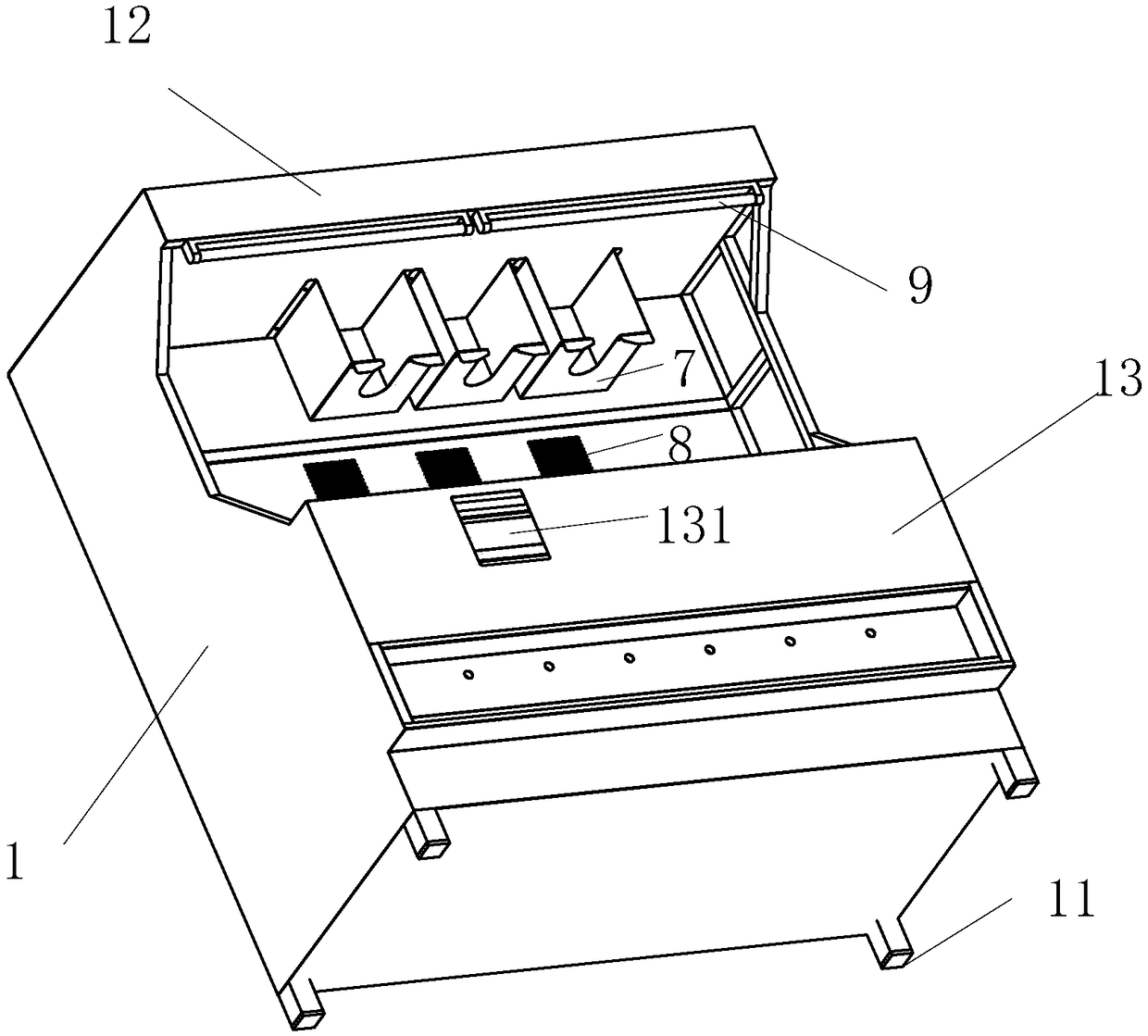

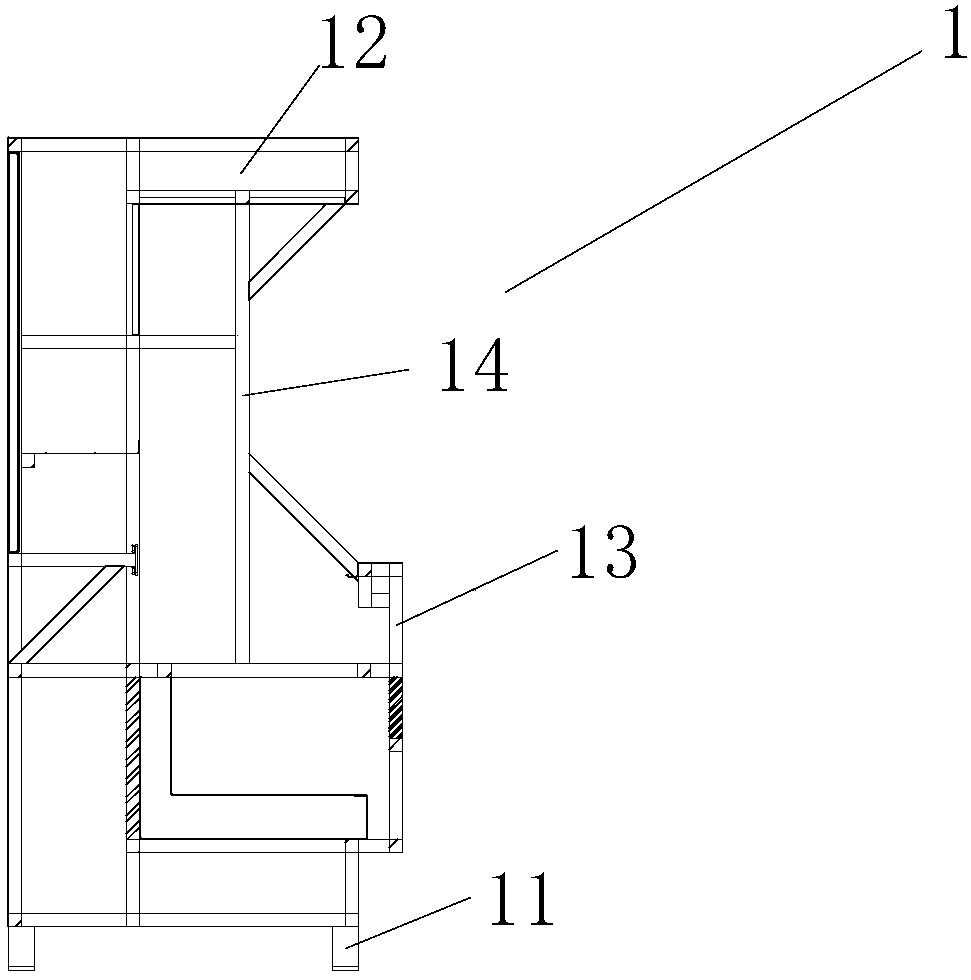

[0045] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale. Unless the context clearly requires, throughout the specification and claims, "comprises", "comprises" and similar words should be interpreted in an inclusive sense rather than an exclusive or exhaustive meaning; that is, "including but not limited to" meaning.

[0046] It should be understood that the automatic frying device for fried food of the present invention can be used for frying various cake-shaped foods. In this application, cake-shaped foods are taken as an example to describe the composition and use process of the device. In addition, in the description of the present invention, unless otherwise specified, "plurality" means two or more.

[0047] In this app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com