Cigarette blasting bead sterile single-particle release pen

A technology of aseptic sheet and popping beads, which is applied to tobacco, smoker's products, containers to prevent mechanical damage, etc., can solve the problems of inability to store popping beads, falling popping beads, and inconvenient operation for smokers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

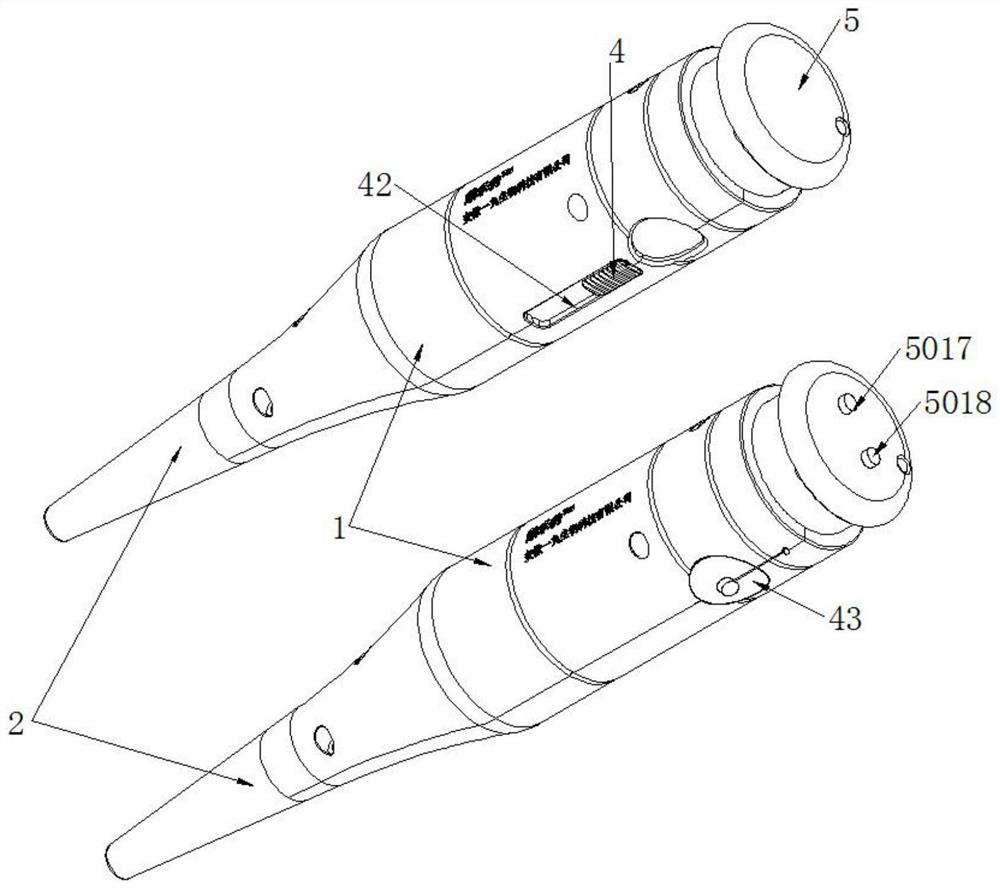

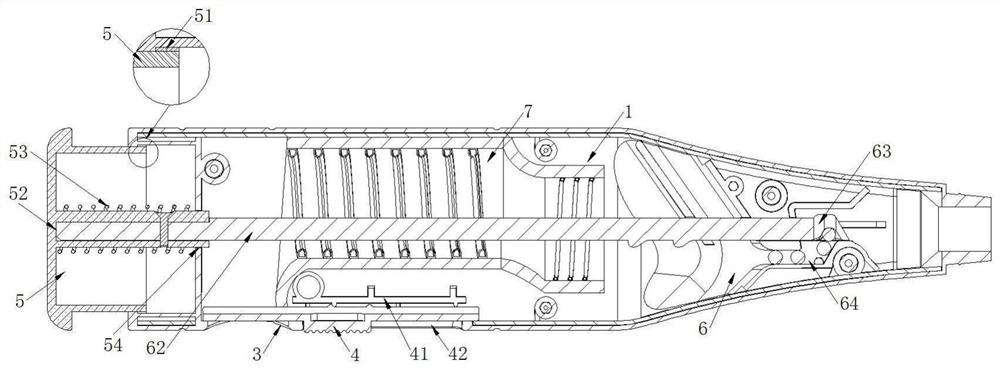

[0050] refer to Figure 1-6 and Figure 12-13 , a cigarette popping aseptic single grain release pen, comprising a shell 1, a tapered feeding head 2, a driving device, a feeding device and a protective device.

[0051] The upper end of the conical blanking head 2 is threadedly connected with the outer surface of the lower end of the housing 1 .

[0052] refer to Figure 1-2 , Figure 4 and Figure 12-13 , the protective device is arranged on the inner wall of the middle part of the housing 1. In order to seal the feeding port 3, a sealing member is arranged on the inner wall of the feeding port 3. The sealing member is composed of a push block 4 and a limit clamp plate 41. Through the limit card The plate 41 limits the position of the push block 4, and when the push block 4 is pushed upward, it seals the feeding port 3;

[0053] In order to protect the cigarette popping beads inside the housing, a protective strip 72 is fixed on the inner walls of the first protective she...

Embodiment 2

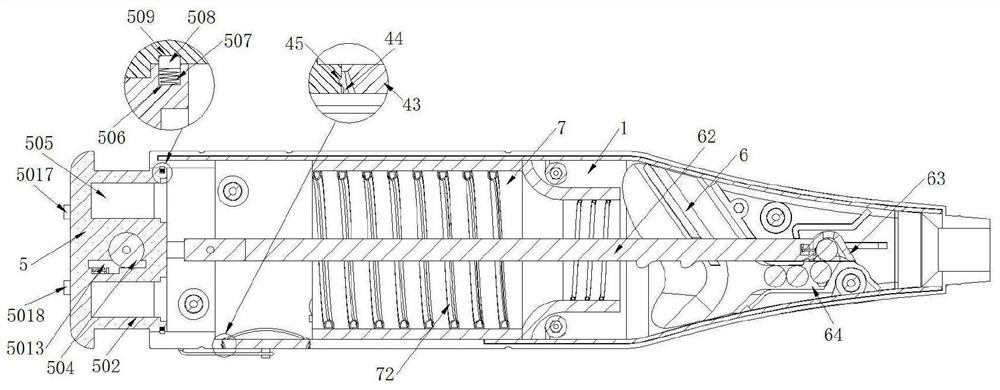

[0057] refer to figure 1 and Figure 3-11 , a cigarette popping aseptic single grain release pen, comprising a shell 1, a tapered feeding head 2, a driving device, a feeding device and a protective device.

[0058] The upper end of the conical blanking head 2 is threadedly connected with the outer surface of the lower end of the housing 1 .

[0059] refer to figure 1 , image 3 and Figure 12-13 , the protective device is arranged on the inner wall of the middle part of the housing 1. In order to seal the feeding port 3, a sealing member is arranged on the inner wall of the feeding port 3, and the sealing member is formed by a chuck 43 and a spring buckle 44 arranged on the side of the chuck 43. 1. The card slot provided on the inner surface of the feeding port 3 is formed by inserting the chuck 43 into the feeding port 3, and snapping into the card slot 45 provided in the feeding port 3 through the spring buckle 44 on the side of the chuck 43 , and then seal the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com