Garbage pyrolysis gasification furnace and method

A technology for pyrolysis gasification and waste, which is used in coke ovens, special forms of dry distillation, petroleum industry, etc. It can solve the inconvenience of waste pyrolysis furnace gasification for long-term, efficient and stable operation, uneven distribution of waste, and easy clogging of the furnace by ash and slag. Cavity and other problems, to achieve the effect of convenient and continuous long-term operation, reducing labor intensity and increasing spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

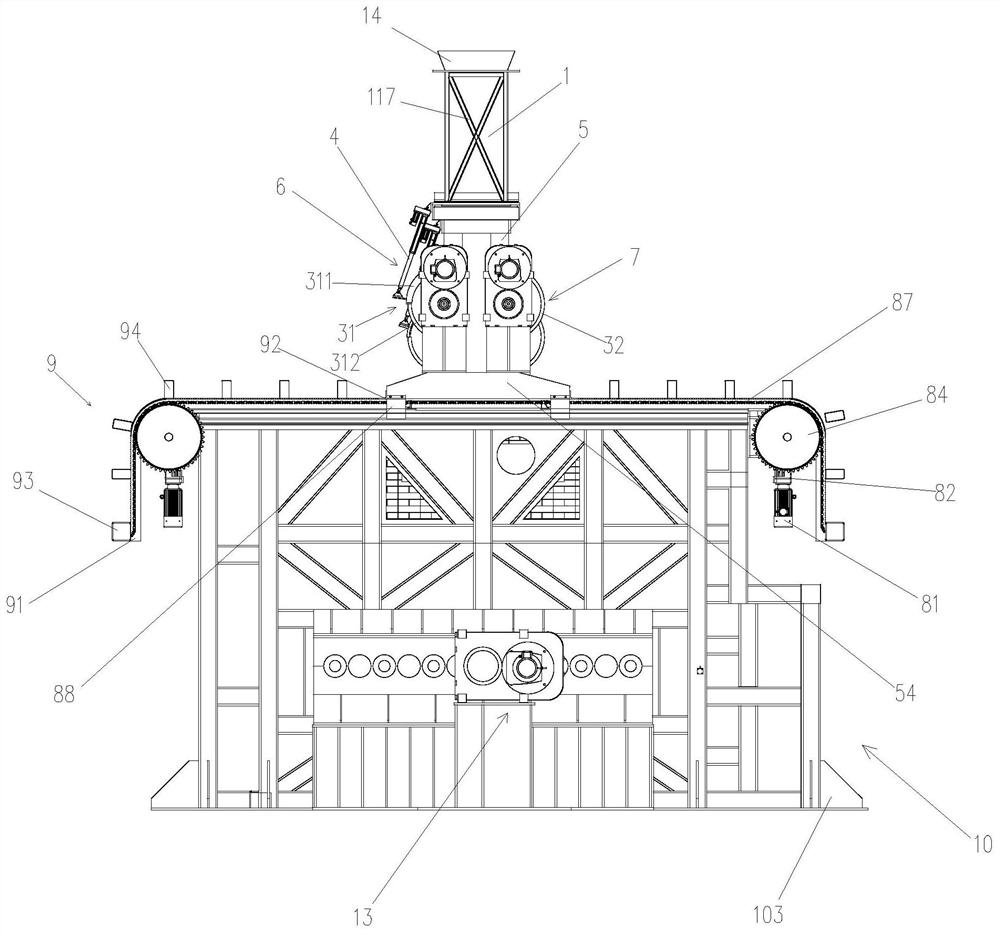

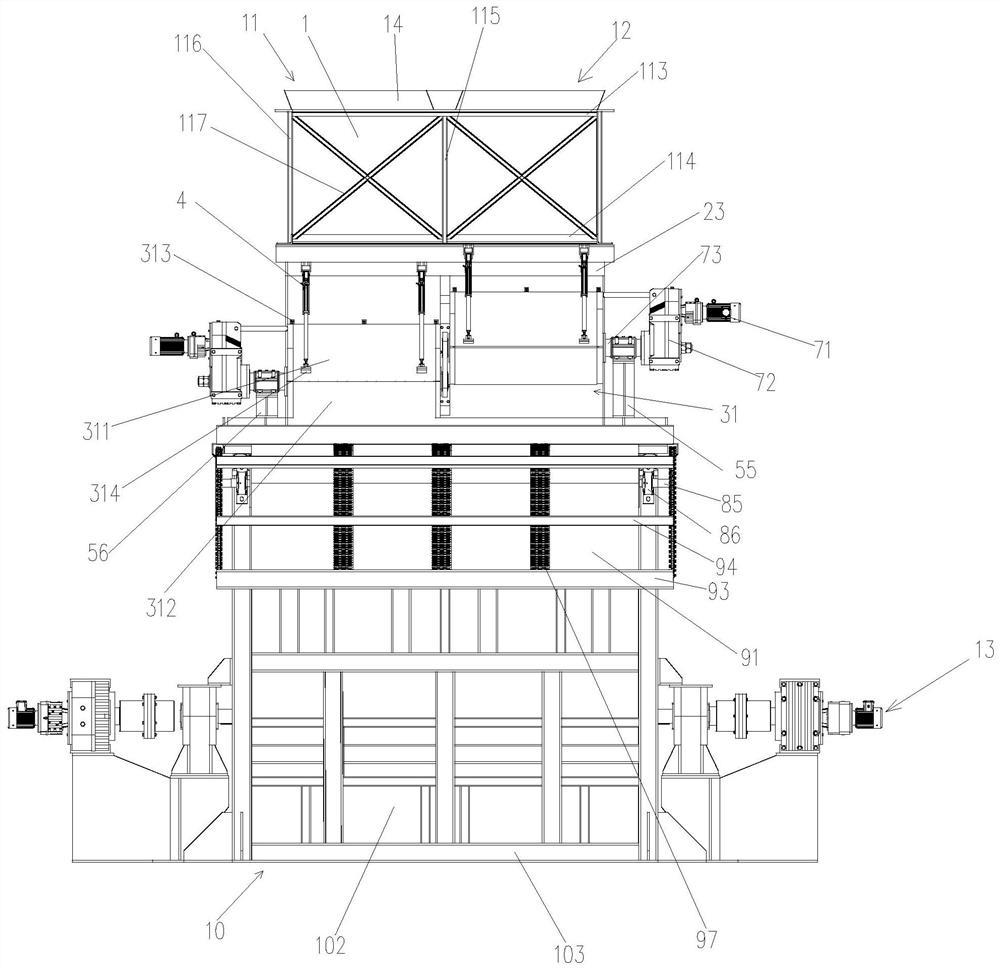

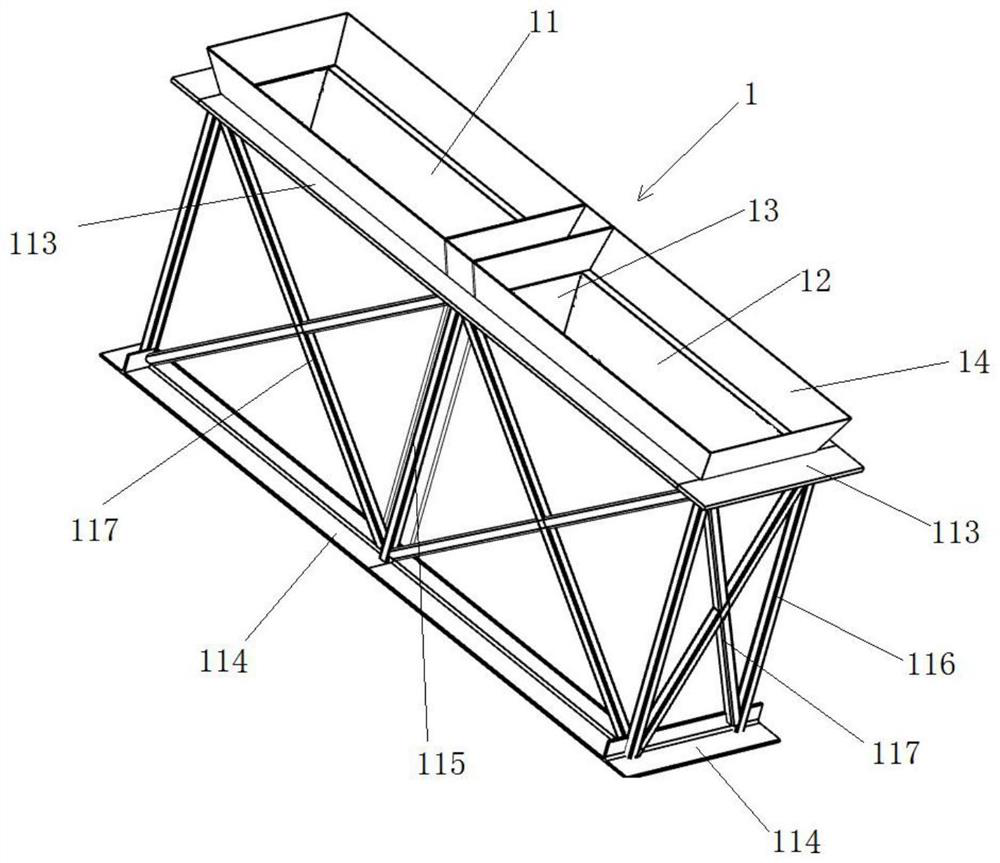

[0095] Such as figure 1 , figure 2 and Figure 14 As shown, the present invention includes a furnace body 10, a moving device arranged on the top of the furnace body 10 and a feeding mechanism connected with the moving device, and the moving device drives the feeding mechanism along the furnace body 10. The length direction of the port 101 reciprocates, and the feeding mechanism communicates with the furnace body 10, so that the garbage in the feeding mechanism enters the furnace body 10, and the furnace body 10 is used to pyrolyze the incoming garbage. The furnace body 10 is provided with a rotary toggle mechanism 13, one side of the furnace body 10 is provided with an ash bin 16, and the side of the furnace body 10 close to the ash bin 16 is provided with a baffle member;

[0096] The unloading mechanism, the moving device and the rotary toggle mechanism 13 are all controlled by a monitoring module.

[0097] In this embodiment, the unloading mechanism includes an unloadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com