Method for transforming yarn spinning and/or twisting machine and modified yarn spinning and/or twisting machine resulting from said method

The technology of a kind of spinning machine, twisting machine, is used in the field that is used to transform yarn spinning machine and/or twisting machine and the improved yarn spinning machine and/or twisting machine obtained by above-mentioned, can solve Improve expensive, difficult to implement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In view of the above figures, and according to the numbering adopted, in addition to examples of improved machines according to the prior art, there can be seen exemplary and non-limiting examples of twisting and / or spinning machines improved according to the invention The embodiment includes the parts and elements pointed out and described in detail below.

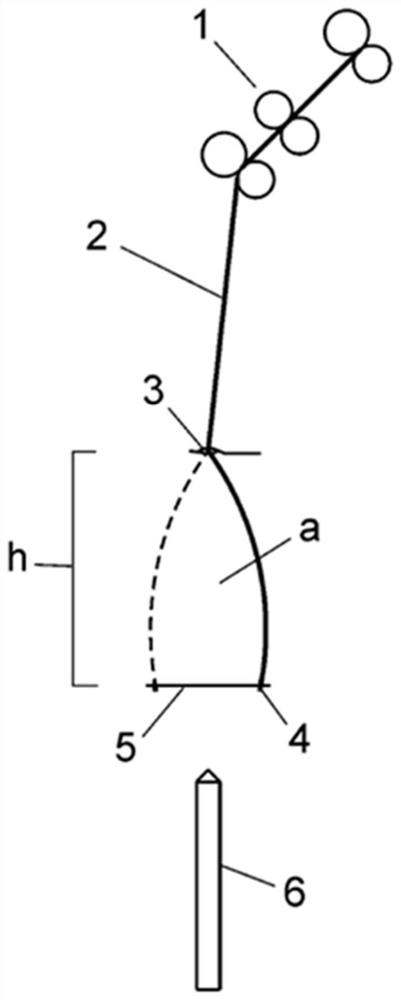

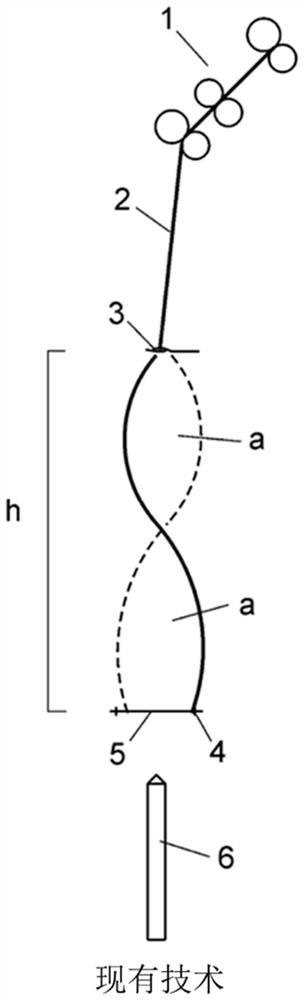

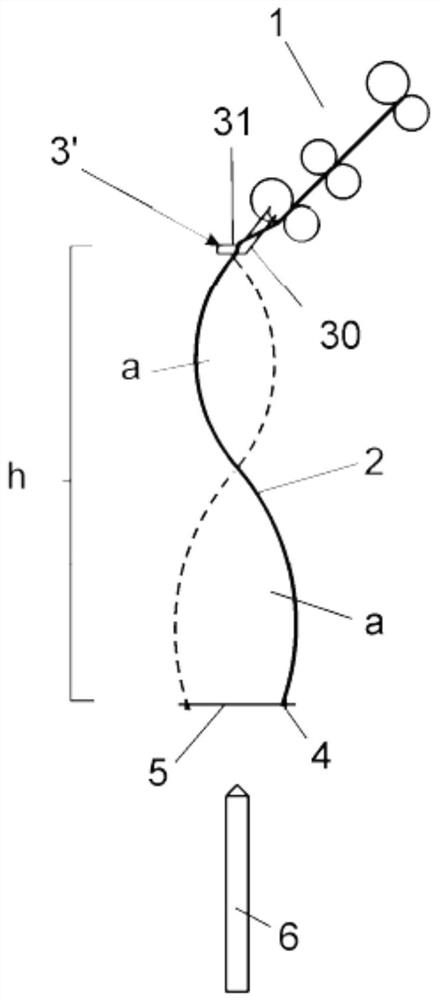

[0036] therefore, figure 1 The basic elements of an unmodified conventional ring-spun yarn twister and / or spinning machine are shown very schematically, that is to say it has only a single balloon area (a), which basically consists of the following elements Composition: yarn (2) feeding device (1), preferably a set of standard rollers; conventional guiding device (3), located at a certain distance below the feeding device (1) and delimiting said balloon above the upper end of zone (a); and the twisting device (4) and winding device (5) of said yarn (2) perpendicular to the pick-up spool (6), which is preferably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com