Isolating switch of inflatable switch cabinet

A technology of isolating switch and switchgear, which is applied in the direction of air switch components, switchgear setting, switchgear, etc., can solve the problems of low work efficiency and slow installation speed, achieve fast installation speed, improve heat dissipation effect, and extend service life Effect of Life and Replacement Periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

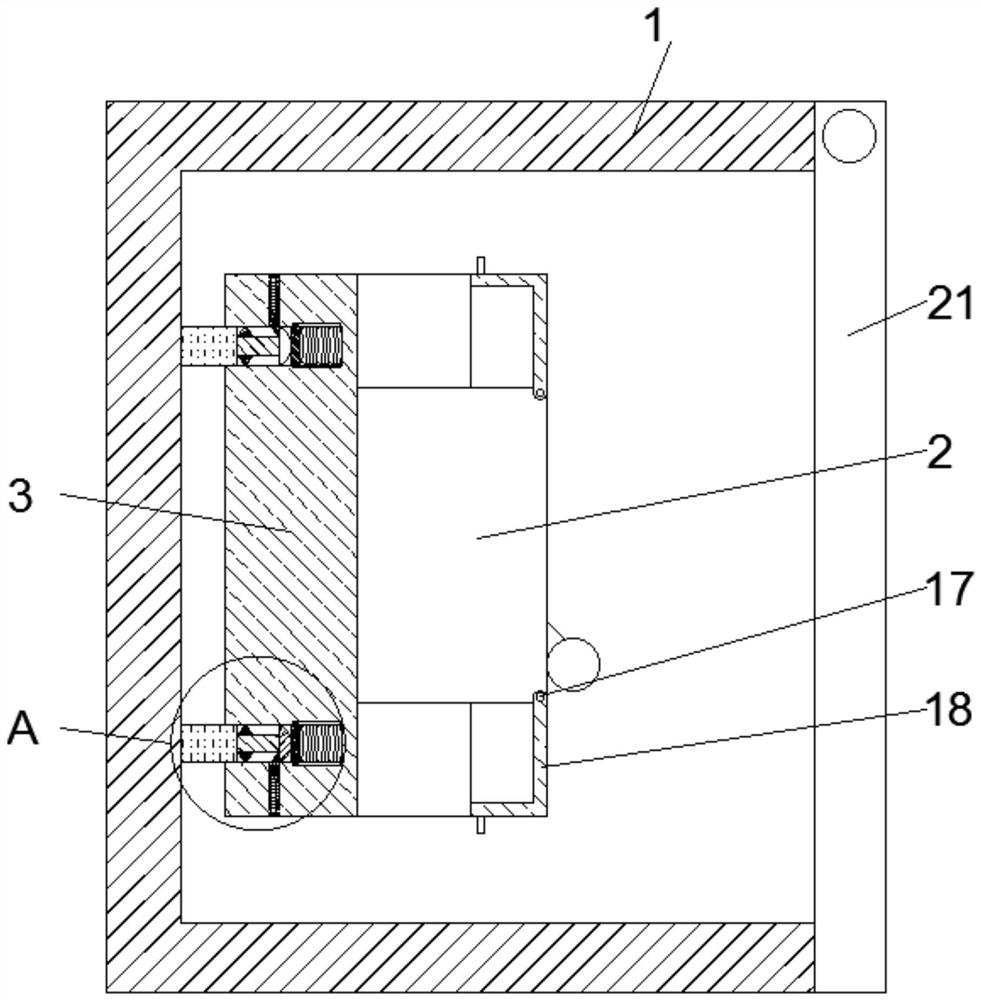

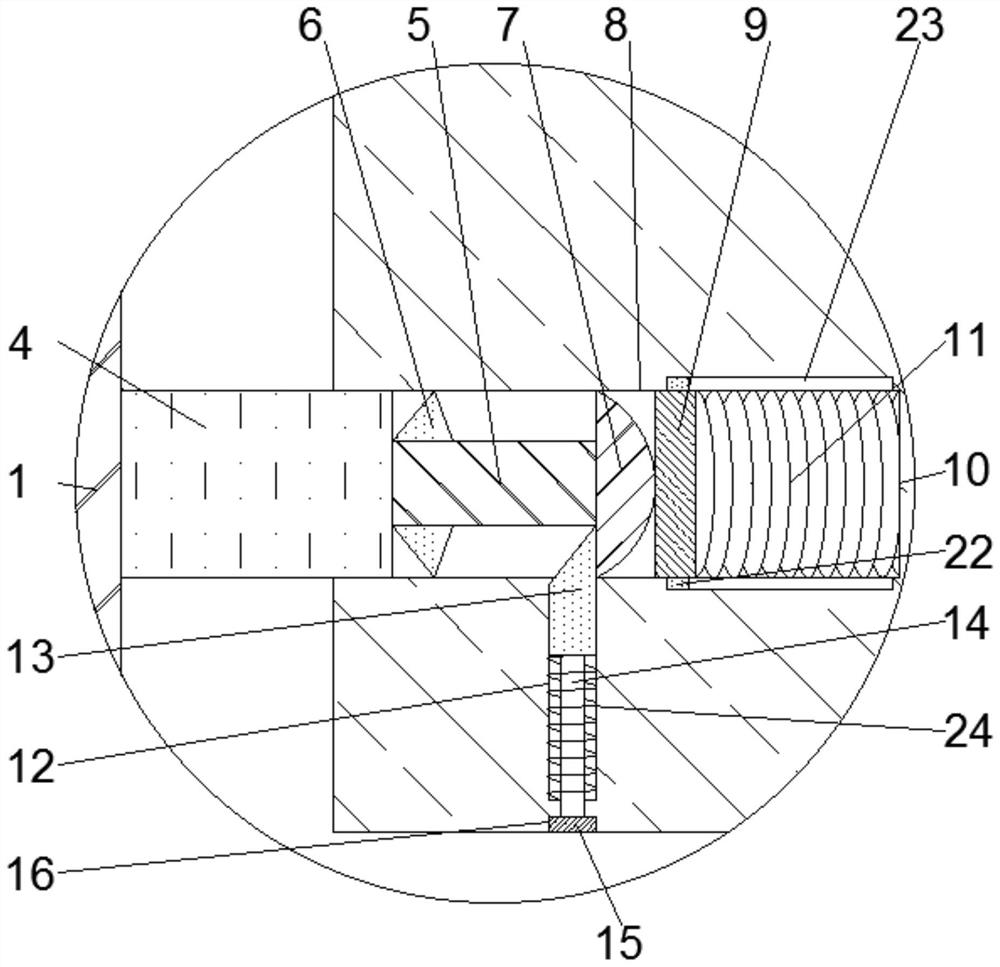

[0024] see Figure 1-3 , according to an embodiment of the present invention, an isolating switch of an inflatable switchgear, comprising a switchgear 1, the isolating switch body 2 is installed in the switchgear 1, and the isolating switch body 2 is fixed on a side close to the switchgear 1 A mounting plate 3 is connected, and the four corners of the switch cabinet 1 close to the mounting plate 3 are fixedly connected with a fixed block 4, and the side of the fixed block 4 away from the switch cabinet 1 is fixedly connected with a slide bar 5, so The outer surface of the slide bar 5 is slidably connected with a slider 6, and the end of the slide bar 5 away from the fixed block 4 is fixedly connected with a semicircle block 7, and the mounting plate 3 is provided with a card near the semicircle block 7. Connecting hole 8, the clamping hole 8 is adapted to the semicircular block 7 and the fixed block 4, one side of the clamping hole 8 is provided with an extrusion plate 9, and ...

Embodiment 2

[0026] see Figure 1-3 , the buckle mechanism includes a cavity two 12, a block 13, a push rod 14, a limit block 15 and a spring two 24, and the mounting plate 3 is provided with a cavity two 12 near the semicircular block 7, and the A block 13 is slidably connected to the cavity two 12, and the end of the block 13 away from the semicircular block 7 is fixedly connected with a push rod 14, and the end of the push rod 14 away from the block 13 passes through the mounting plate And extend to the limit block 15, the limit block 15 is fixedly connected with the push rod 14, the outer surface of the push rod 14 is provided with a spring two 24, the clamp block 13 and the semicircular block 7 Matching, the clamping block 13 is matched with the slider one 6, and the mounting plate 3 is provided with a groove 16 close to the limiting block 15, and the limiting block 15 and the groove 16 Compatible, stable installation, not easy to fall.

Embodiment 3

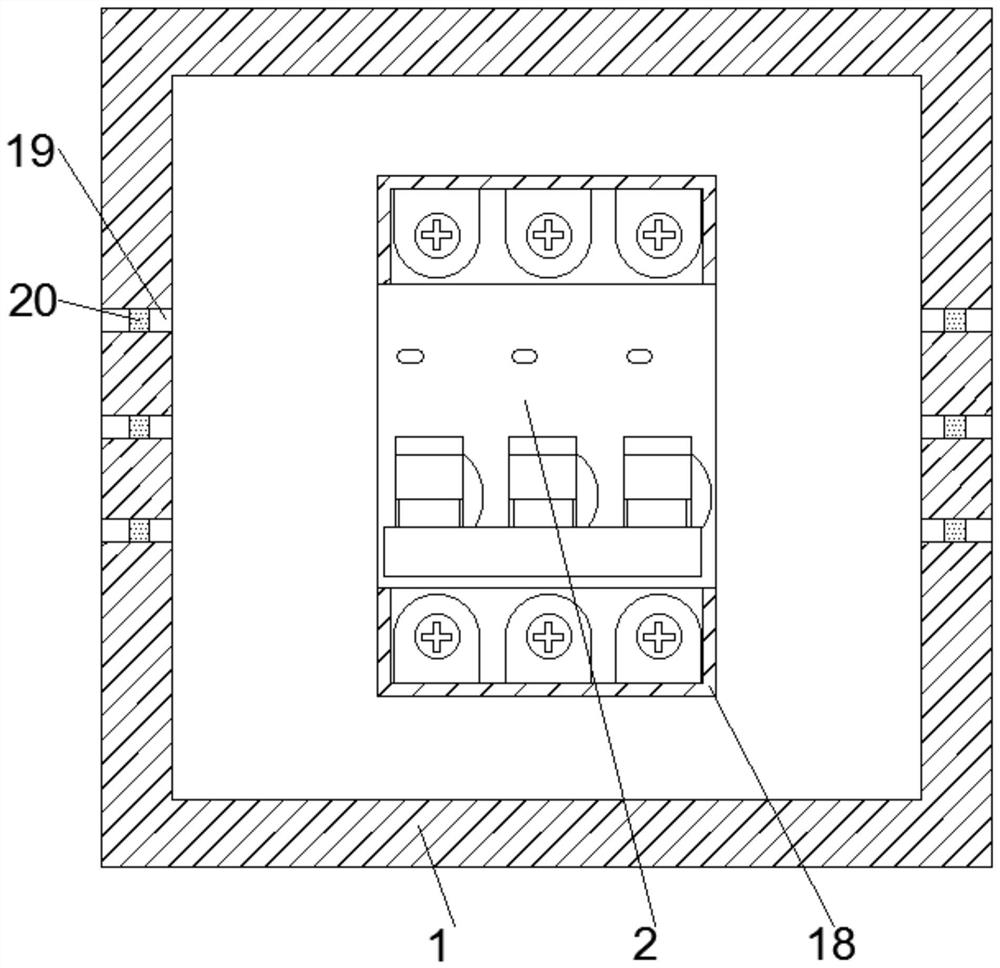

[0028] see Figure 1-3 , the two ends of the isolating switch body 2 away from the mounting plate 3 are movably connected with a rotating shaft 17, and the outer surface of the rotating shaft 17 is fixedly connected with a protective shell 18, which isolates the wiring bolts on the isolating switch body 2 To prevent accidental electric shock, the two sides of the switch cabinet 1 are provided with heat dissipation holes 19, and the heat dissipation holes 19 are fixedly connected with a dust-proof net 20, which improves the heat dissipation effect of the isolating switch body 2 in the switch cabinet 1, The service life and replacement cycle of the isolating switch body 2 are extended, the cost is reduced and the dustproof effect is good. One side of the switch cabinet 1 is hinged with a protective cover 21 to protect the isolating switch body 2. The extrusion plate 9 Two sliders 22 are fixedly connected at both ends, and a slide groove 23 is opened in the first cavity 10 close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com