Ultra-low profile slot array antenna and manufacturing method

A technology of slot antenna and array antenna, which is applied to slot antenna, antenna, antenna array and other directions, can solve the problem of inability to further realize ultra-low profile, so as to improve dynamic performance and stealth performance, improve space utilization rate, and improve corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

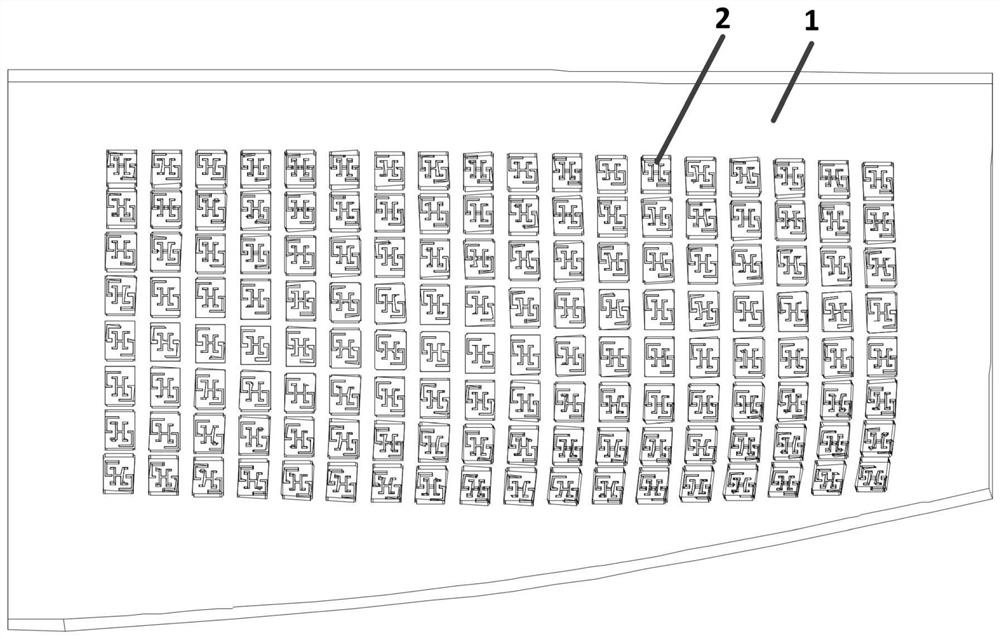

[0031] The ultra-low profile slot array antenna of the present invention includes a complex carrier 1 and a diagonal slot antenna unit 2 , and the diagonal slot antenna unit 2 is arranged on the complex carrier 1 .

[0032] The surface of the complex carrier 1 is an arbitrary curved surface, which generally has a two-dimensional curvature. Since the diagonal slot antenna unit 2 needs to sink into the complex carrier 1, the surface of the complex carrier 1 is divided into many curved surface units with similar shapes, and each of the curved surface units is delineated backward. The extension provides space for the slot antenna. The material of the complex carrier 1 is generally set to be metal.

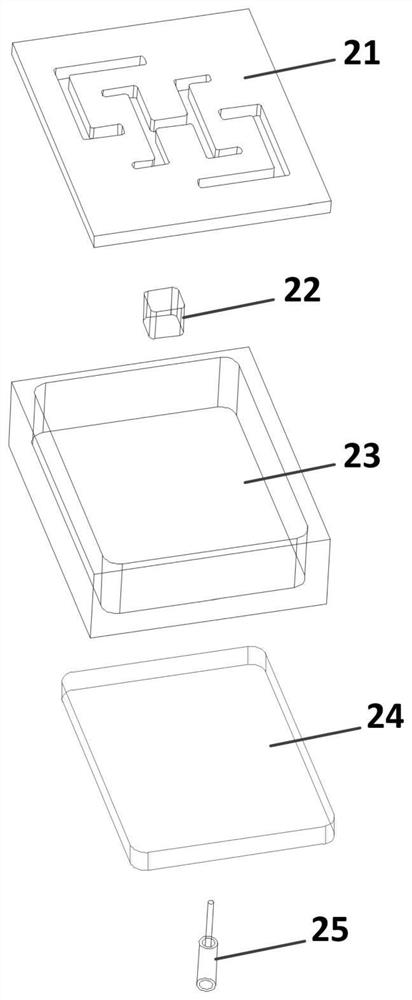

[0033] The diagonal slot antenna unit 2 includes a slot plate 21, a resonant cavity 23, an impedance matching block 22, a resonant cavity back plate 24 and a feed structure 25; the slot plate 21 is a part of the complex carrier 1, Located at the top of the diagonal slot antenna unit ...

Embodiment 2

[0051] Such as figure 1 as shown, figure 1 It is a structural view of the ultra-low profile slot array antenna; in this embodiment, the ultra-low profile slot array antenna of the present invention is composed of 144 diagonal slot antenna units 2, working at 4.5-4.7GHz , the diagonal slot antenna units 2 are arranged in a rectangular grid, and Cosmol is used for grid division. The complex carrier 1 is intercepted from a certain aircraft body, and the curved surface shape of the complex carrier 1 is determined according to the aerodynamic performance. design, which cannot be characterized by parameters, the antenna is modeled according to the above method.

[0052] Such as figure 2 as shown, figure 2 It is a structural view of the diagonal slot antenna unit; the diagonal slot antenna unit 2 includes the slot plate 21, the impedance matching block 22, the resonant cavity 23, and the resonant cavity back The plate 24 and the feed structure 25, the outer dimension of the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com