Starch nanoparticles prepared by jet cavitation assisted enzymolysis and preparation method and application

A starch nano-assisted enzymatic hydrolysis technology, which is applied in the field of starch industry, can solve the problems of long preparation time of starch nanoparticles, unsuitability for industrial production, complex preparation process, etc., and achieve the effect of high efficiency, environmental protection, low price and energy saving in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

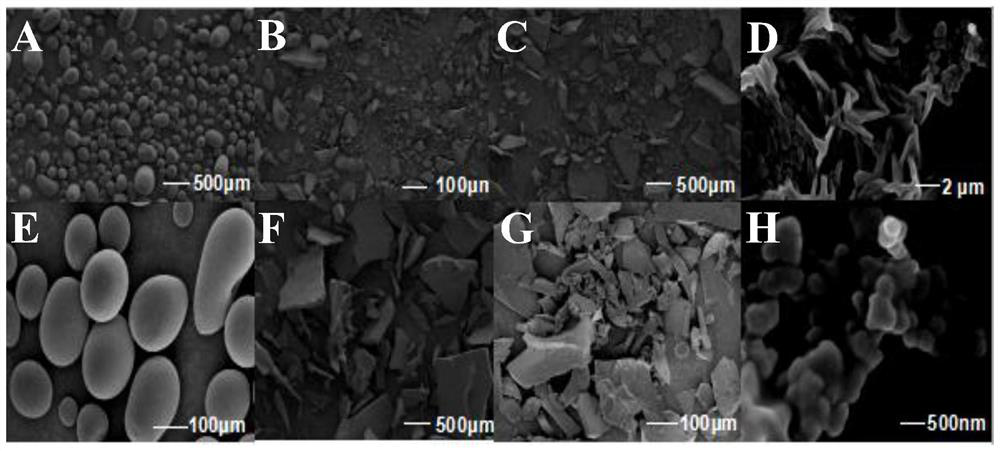

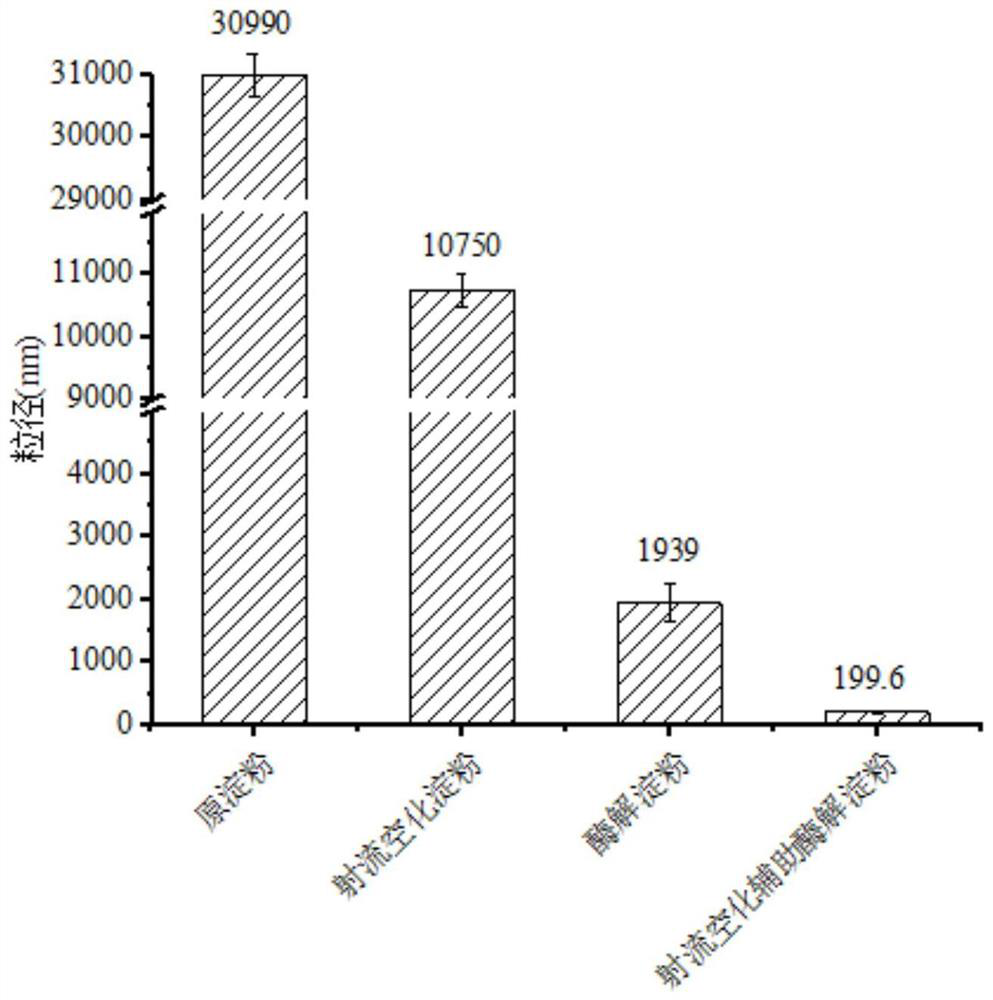

Embodiment 1

[0050] The potato starch and distilled water were mixed at a ratio of 1:2, and the starch suspension was prepared by magnetic stirring at room temperature for 30 min. 100 mL of starch suspension was subjected to jet cavitation treatment for 5 minutes at a temperature of 30°C and normal pressure. Put the starch suspension after jet cavitation into a 45°C oven to dry, pulverize, and pass through a 100-mesh sieve. Take 2 g of the dried potato starch sample and mix it with 20 mL of distilled water to form a 10% starch suspension, stir and gelatinize in a boiling water bath for 30 min, cool down to 60 °C, add 20 mL of acetic acid-sodium acetate buffer, add pullulan The enzyme was hydrolyzed for 3 hours under the appropriate reaction conditions. The amount of enzyme added was 5U / g, the temperature of the hydrolysis was 55°C, and the pH value of the hydrolysis was 4.5. After that, the enzyme was deactivated in a boiling water bath for 30 minutes, then placed in a 45°C oven for drying...

Embodiment 2

[0052] The potato starch and distilled water were mixed at a ratio of 1:2, and the starch suspension was prepared by magnetic stirring at room temperature for 30 min. 100 mL of starch suspension was subjected to jet cavitation treatment for 5 minutes at a temperature of 30°C and normal pressure. Put the starch suspension after jet cavitation into a 45°C oven to dry, pulverize, and pass through a 100-mesh sieve. Take 2 g of the dried potato starch sample and mix it with 20 mL of distilled water to form a 10% starch suspension, stir and gelatinize in a boiling water bath for 30 min, cool down to 60 °C, add 20 mL of acetic acid-sodium acetate buffer, add pullulan The enzyme was hydrolyzed for 3 hours under the enzymatic suitable reaction conditions. The amount of enzyme added was 8 U / g, the enzymatic hydrolysis temperature was 60 °C, and the pH value of the enzymatic hydrolysis was 4.5. After that, the enzyme was deactivated in a boiling water bath for 30 min, put into a 45 °C ov...

Embodiment 3

[0054] The potato starch and distilled water were mixed at a ratio of 1:2, and the starch suspension was prepared by magnetic stirring at room temperature for 30 min. 100 mL of starch suspension was subjected to jet cavitation treatment for 5 minutes at a temperature of 30°C and normal pressure. Put the starch suspension after jet cavitation into a 45°C oven to dry, pulverize, and pass through a 100-mesh sieve. Take 2 g of the dried potato starch sample and mix it with 20 mL of distilled water to form a 10% starch suspension, stir and gelatinize under boiling water bath conditions for 30 min, cool down to 60 °C, add 20 mL of acetic acid-sodium acetate buffer, add ordinary Lulanase was enzymatically hydrolyzed under suitable reaction conditions for 2 hours, the amount of enzyme added was 4U / g, the enzymatic hydrolysis temperature was 60 °C, the enzymatic hydrolysis pH was 4.5, and then the enzyme was inactivated in a boiling water bath for 30 min. Put it into a 45°C oven for d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com