Tool for central area of BNCT accelerator and use method

A central area and accelerator technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems that cannot be popularized and used in batches, the difficulty of installing equipment, and the decline in installation accuracy, and achieve the effect of low cost, high precision, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

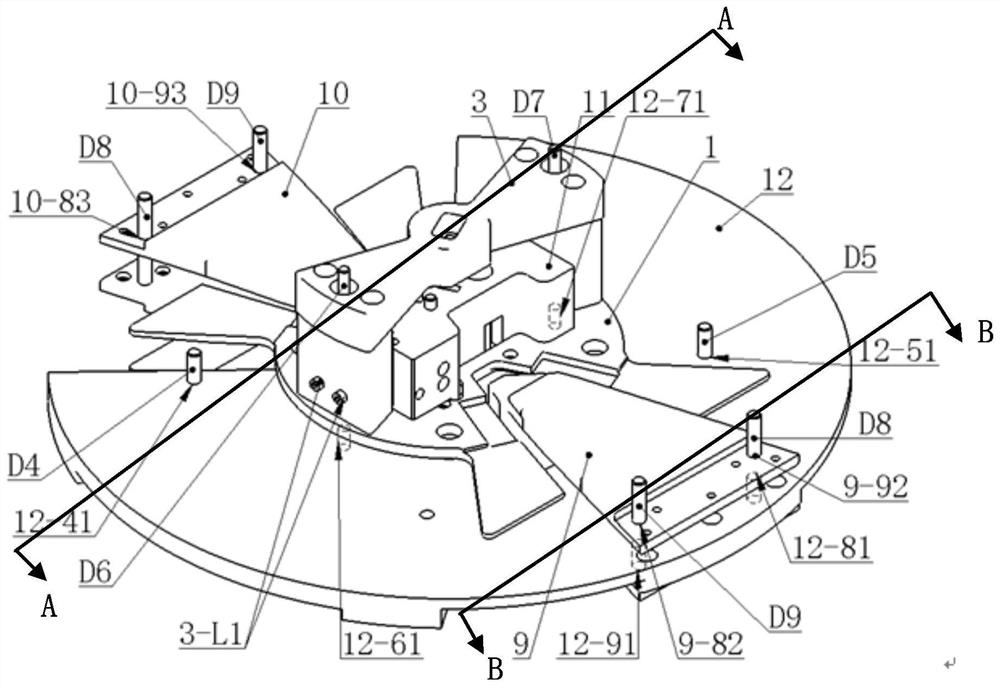

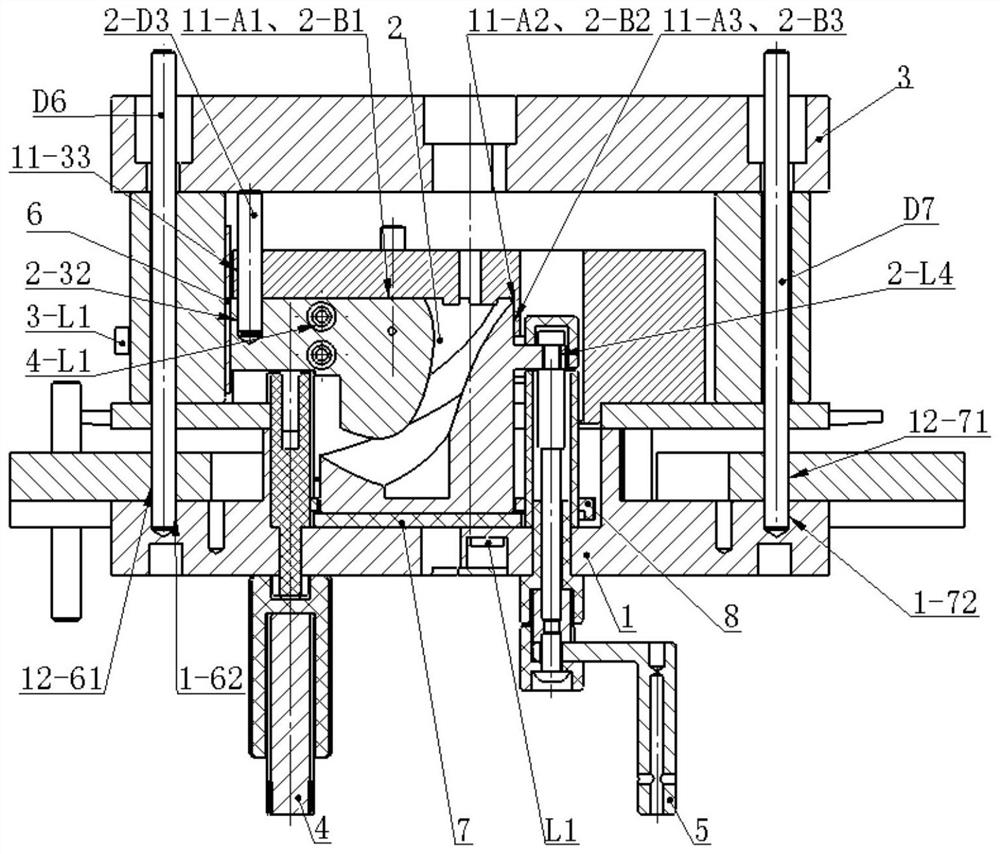

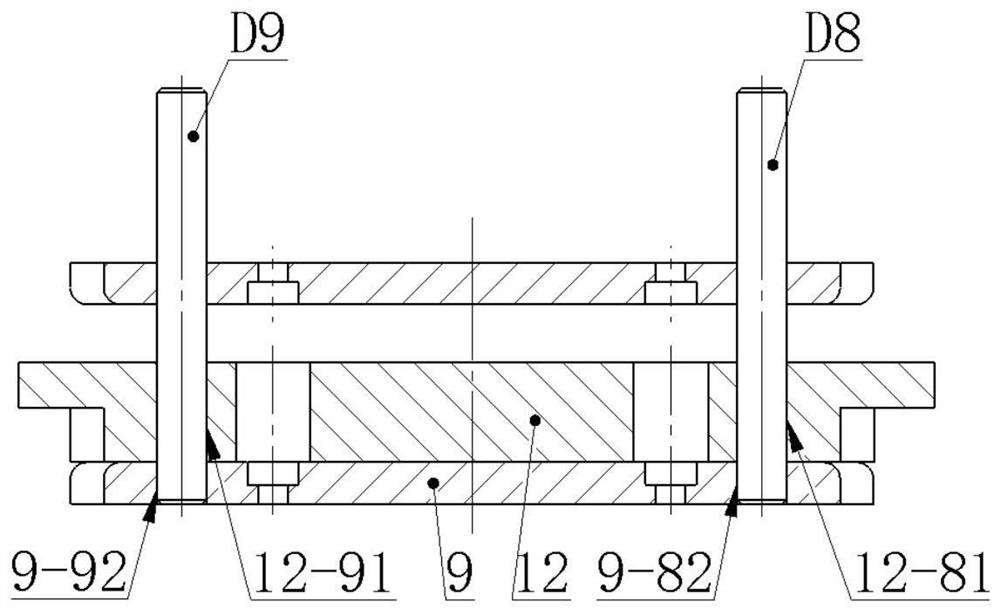

[0067] Design principle of the present invention

[0068]1. Replace man-made experience with tooling. The artificial experience method is to coordinate the error of each installation hole, but the installation result has a large deviation based on artificial experience, and the total error cannot be zero, and the deviation and absolute position of each installation are different, resulting in low installation accuracy. Repeatability is also lower. The feasibility of using tooling instead of human experience lies in the use of precisely matched pins and precise positioning surfaces for positioning, which can ensure the installation accuracy and repeatability of the central area, and avoid the problem of errors caused by the size of the installation holes to the greatest extent. The design idea of the tooling is: the pin hole of each pin on the tooling is precisely designed and calculated in advance, and is precisely matched with the structure of the central area. Taking each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com