Method for fracturing metal component, and method for fracturing connecting rod

A technology of metal parts and parts, applied in the field of fracture of connecting rods, can solve the problem that the fracture surface cannot be obtained, and achieve the effect of suppressing three-dimensional offset and simple cost burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

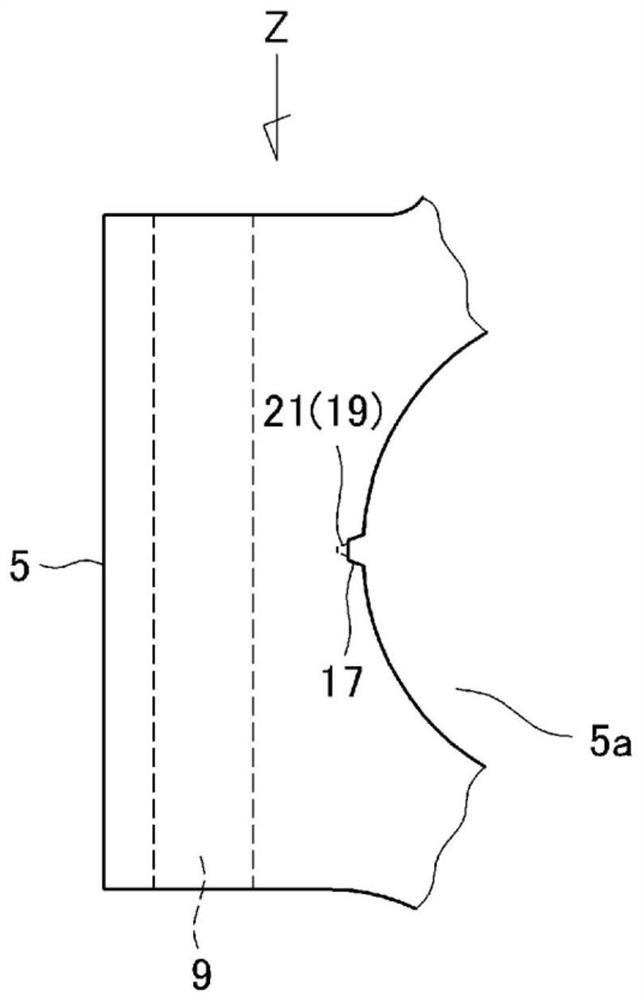

[0038] Below, based on Figure 1 to Figure 10 The shown first embodiment describes the present invention.

[0039] figure 1 A front view of a connecting rod 1 (hereinafter referred to as connecting rod 1 ) as a product is shown.

[0040] The connecting rod 1 has: a small end portion 3 having a piston pin hole 3a, a large end portion 5 having a crank pin hole 5a (equivalent to a prescribed through hole in the present application), and the small end portion 3 and the large end portion. Rod 7 to which ends 5 are joined. In addition, a pair of bolt holes 9 (one each on the left and right sides) located on the side of the crank pin hole 5 a are provided in the large end portion 5 . In addition, the bolt hole 9 is formed by a hole extending in a direction perpendicular to the crank pin hole 5a.

[0041] The large end portion 5 is divided into a main body portion 15a and a semicircular arc-shaped cover portion 15b so that a crank pin (not shown) can be sandwiched therein. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com