Edible tubular food casings

A technology for coating and food, applied in the directions of food ingredients, food forming, application, etc., can solve the problems of self-supporting coating without teaching, not being able to be used to manufacture various types, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

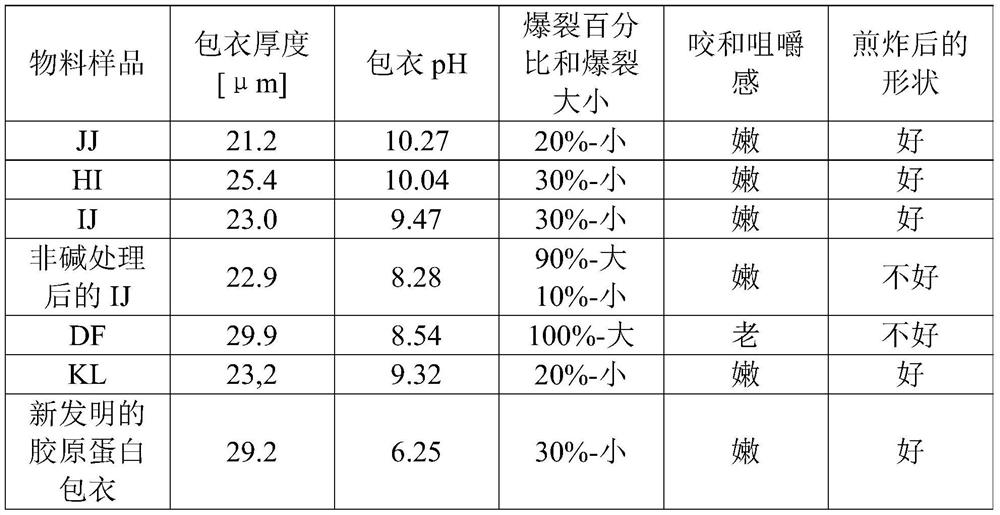

Examples

Embodiment

[0110] The invention will now be explained in more detail by means of exemplary embodiments, from which further characteristics, properties and advantages of the invention are derived. The examples are not limiting.

[0111] It should also be understood that each feature disclosed in one or more embodiments described is not only disclosed in the context of a specific embodiment, but also disclosed in a general sense. Therefore, those skilled in the art can freely combine these features with other features of the present invention

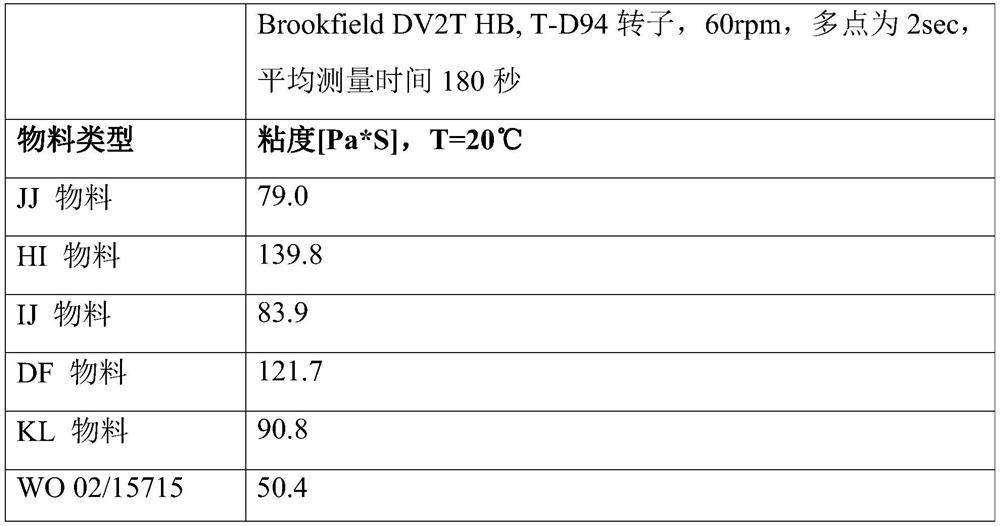

[0112] 1. Viscosity measurement

[0113] Viscosity was measured using a Brookfield DV2T HB viscometer. To do this, 250ml plastic cups with the material to be tested are filled to the brim and free of air. The temperature of the material should be kept constant. Viscosity measurements were performed at 20°C. If necessary, cool the material in a refrigerator or warm it in a heating cabinet. Check the level on the viscometer before each use and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com