Resonance structure and silencer composed of resonance structure

A technology of resonance structure and resonance plate, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of narrow muffler frequency band and application limitation of resistant mufflers, etc., and achieve narrow noise reduction band, obvious synergistic effect, and low-frequency noise reduction frequency bandwidth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

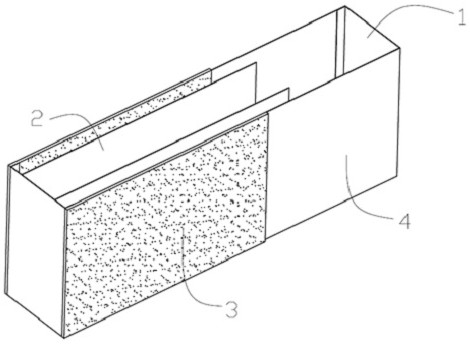

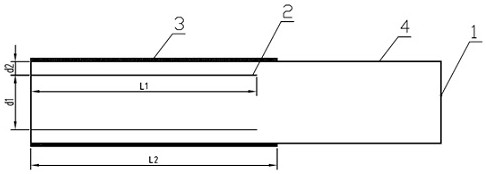

[0035] Such as Figure 1-2 As shown, a resonance structure includes a surrounding sealing plate 1, an internal side resonance plate 2, and a surface resonance plate. The surface resonance plate includes a microporous sound-absorbing plate 3 and a panel 4, and the length of the internal side resonance plate is L1, the length of the microporous sound-absorbing panel is L2, and the width between the two internal side resonance panels is d1; the length L1 of the internal side resonance panel is different from the length L2 of the microporous sound-absorbing panel, where, figure 1 The length of L1 is longer in figure 2 The length of L2 in the middle is longer. By adjusting L1, L2 and d1, different noise reduction requirements can be customized and designed to meet the use of different scenarios, which greatly improves the applicability of the muffler. Among them, L1 and L2 affect the frequency, and d1 affects the frequency. peak.

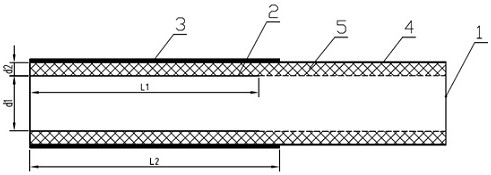

[0036] Such as Figure 3-4 As shown, it furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com