Device and method for reducing ammonia nitrogen in PVDC resin production wastewater

A technology for producing wastewater and ammonia nitrogen, applied in chemical instruments and methods, water pollutants, natural water treatment and other directions, can solve the problems of emergency stop of wastewater discharge, production load reduction, production stop, etc., and achieve effective reduction of ammonia nitrogen and good adjustment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] DETAILED DESCRIPTION OF THE INVENTION The specific embodiments of the present invention will be further described below, and the present embodiment does not constitute a limit to the present invention.

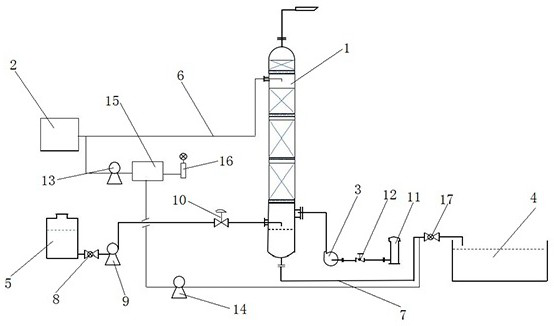

[0022] like figure 1 A ammonia nitrogen cutting device for use in PVDC resin production wastewater, including raw water storage tank 2, aeration tower 1, fan 3, wastewater temporary storage pool 4, ammonia nitrogen detection system, and ammonia nitrogen removing tank 5. The inlet of the original wastewater storage tank 2 and the upper portion of the aeration tower 1 communicates through the water pipe 6; the wind turbine 3 is in communication with the bottom of the aeration tower 1; the wastewater temporary storage pool 4 and the water outlet of the aeration tower 1 pass the water pipe 7 Connect; the ammonia nitrogen removing agent storage tank 5 is connected to the inlet port of the lower portion of the aeration tower 1; the ammonia nitrogen detection system is in communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com