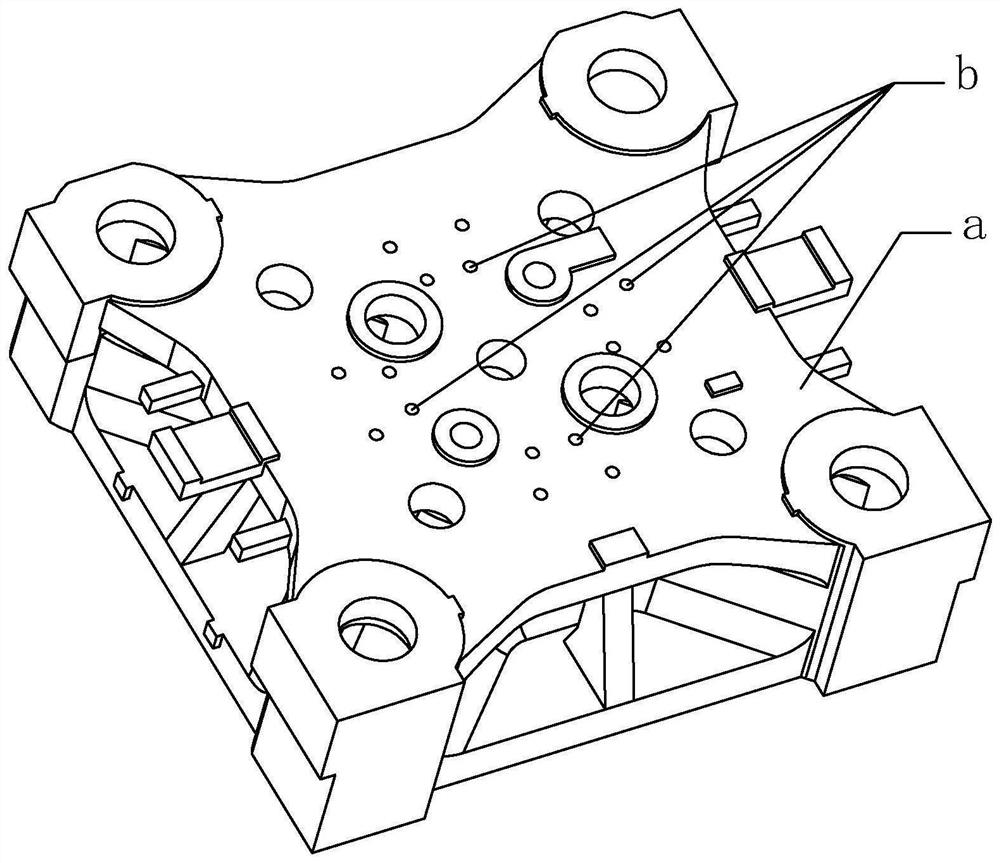

Casting Method of Template Casting for Large Two-Plate Injection Molding Machine

A two-plate, injection molding machine technology, used in casting molding equipment, cores, molds, etc., can solve the problems of the whole machine losing the parallel accuracy of the template, the repeatability of injection molding, the inability to meet high-precision mold production, and casting blowhole defects. , to improve the cooling effect, facilitate adjustment, and reduce shrinkage cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] (1) Weigh the following raw materials by mass percentage: 40% of pig iron, 35% of scrap steel, 25% of returned charge, and recarburizer: 0.9% of the total amount of pig iron, scrap steel and returned charge;

[0095] (2) Put all pig iron, scrap steel, returning charge and recarburizer into the smelting furnace, heat to melt the charge, and add FeSi75-C ferrosilicon after the charge is melted. The amount of ferrosilicon added is pig iron, scrap steel and recycled 0.80% of the total mass of the charge to obtain the original molten iron, and continue to heat the original molten iron to 1440 ° C; the composition and mass percentage of the obtained original molten iron are C3.55%, Si1.45%, Mn 0.20%, P 0.028 %, S 0.023%, the rest is iron;

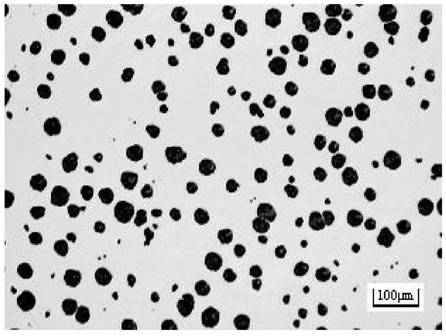

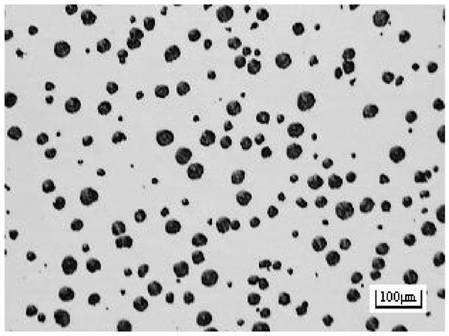

[0096] (3) Spheroidization: The spheroidizing method is used for spheroidization. The spheroidizing dam on one side of the spheroidizing bag is first added with a spheroidizing agent and compacted, and then 0.005% pure antimony of the orig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com