Pre-assembly device for photovoltaic solar tracker and related pre-assembly method

A photovoltaic solar energy, pre-assembly technology, applied in the field of solar power generation, can solve problems such as tracker fracture defects, and achieve the effect of reducing assembly time and installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

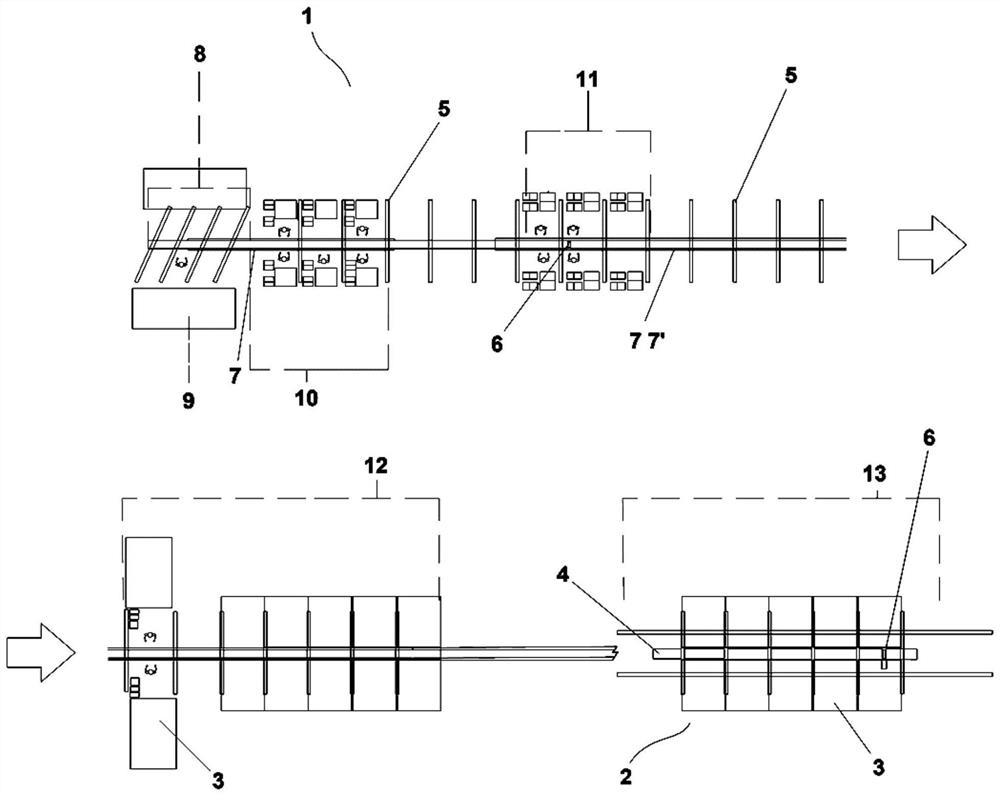

[0060] The following is based on Figure 1-Figure 11 With the information provided in , the invention is described in detail with reference to the preferred embodiments of the invention. The description is intended to illustrate, not to limit, the claimed invention.

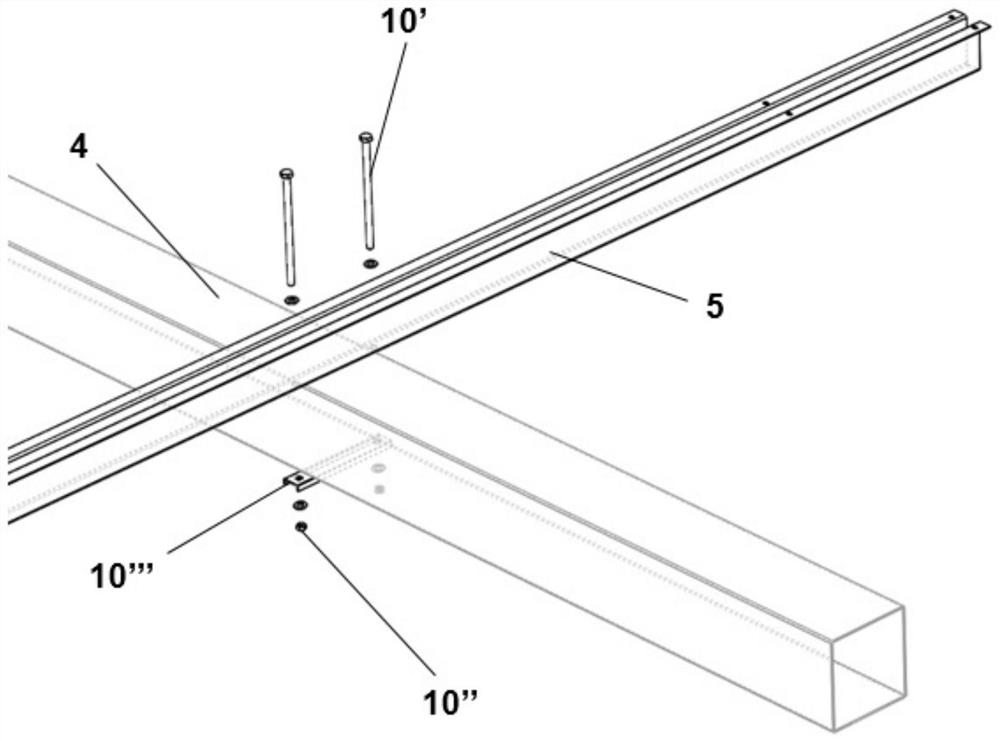

[0061] figure 1 A schematic diagram of a preferred embodiment of the mobile device 1 of the present invention is shown, showing its various parts and main modules. Depicted chronologically from left to right are the various steps in assembling solar units 2 (also referred to as "solar modules" or "units"), each of which consists of a set of main shafts 4 and a plurality of beams 5 (or "purlins") are formed on the structure on which the photovoltaic panels 3 are formed.

[0062] The device 1 of the present invention is preferably installed in an area of the site close to a solar field, or in an actual solar field, from where the completed assembled unit 2 can be moved to a different installation for installin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com