Mounting mechanism for power detection equipment and use method thereof

A technology for testing equipment and electric power testing, which is applied in the direction of measuring devices, measuring device casings, and parts of electrical measuring instruments. Provide installation efficiency and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

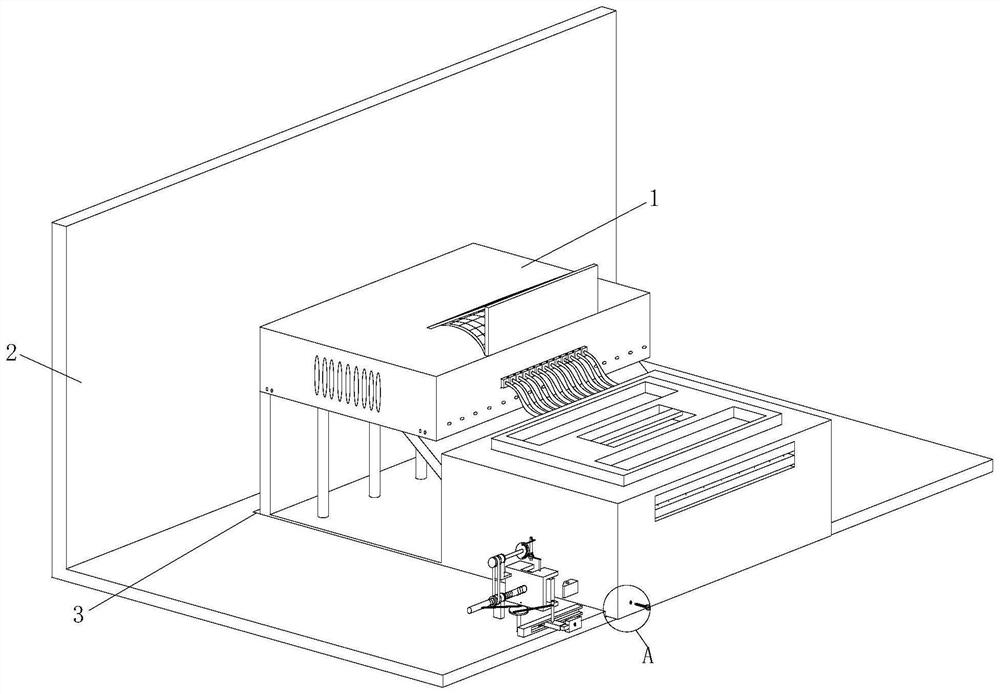

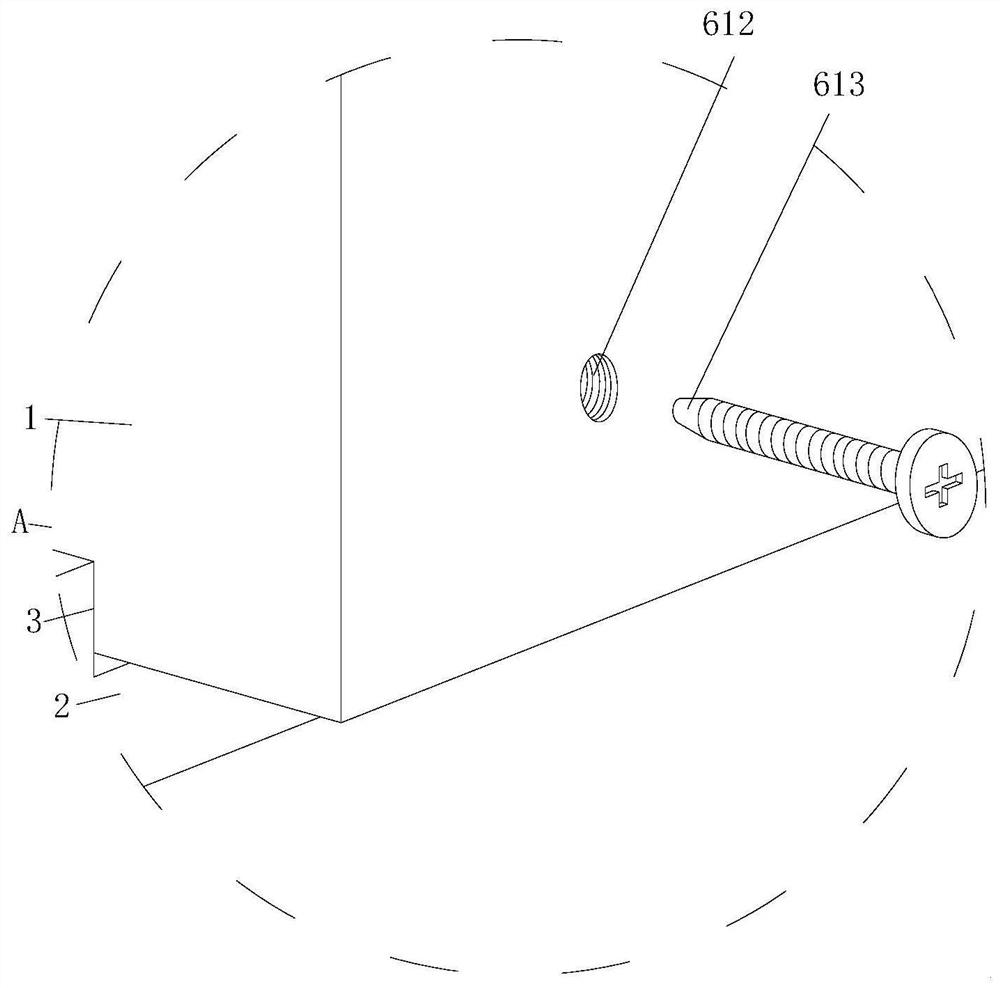

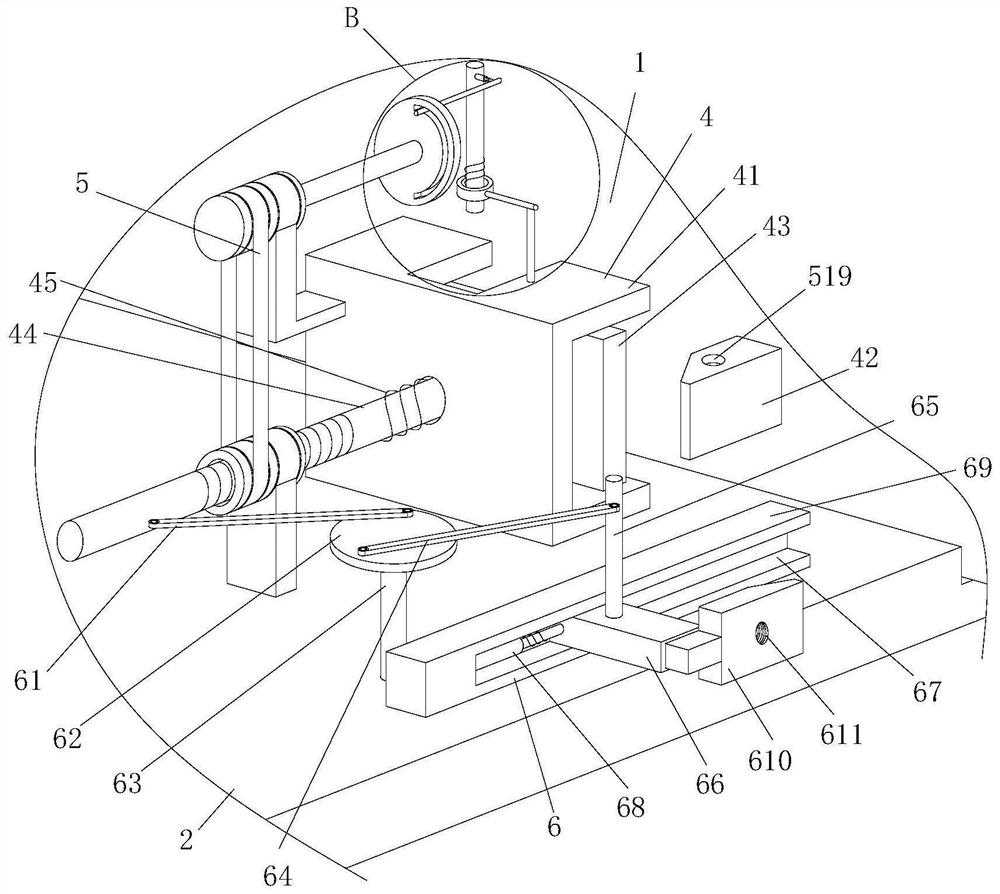

[0037] Attached below Figure 1-5 The present invention is further described with embodiment:

[0038] An installation mechanism for electric power detection equipment and its use method, comprising a detection equipment body 1, a fixed support frame 2 and a positioning chute 3, the positioning chute 3 is set on the fixed support frame 2, and the detection equipment body 1 is movably arranged on the positioning chute In the groove 3, the detection equipment body 1 and the fixed support frame 2 are provided with the same limit mechanism 4, and the setting of the limit mechanism 4 is used to realize the effect of limit locking on the position of the detection equipment body 1, ensuring that the detection equipment body 1 can be stably stored in the positioning chute 3. In the present invention, by modifying the installation structure of the existing detection equipment body 1, the improved installation structure of the detection equipment body 1 can effectively reduce the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com