An external feature detection device for a curved reflector

A technology for external features and detection equipment, applied in gyroscope/steering sensing equipment, measuring devices, surveying and mapping and navigation, etc., can solve the problems of complex occupied area of equipment, deformation and damage of arc-shaped reflectors, complex structure of devices, etc., and achieve shortening The effect of round-trip moving distance, small equipment footprint, and improved fixing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

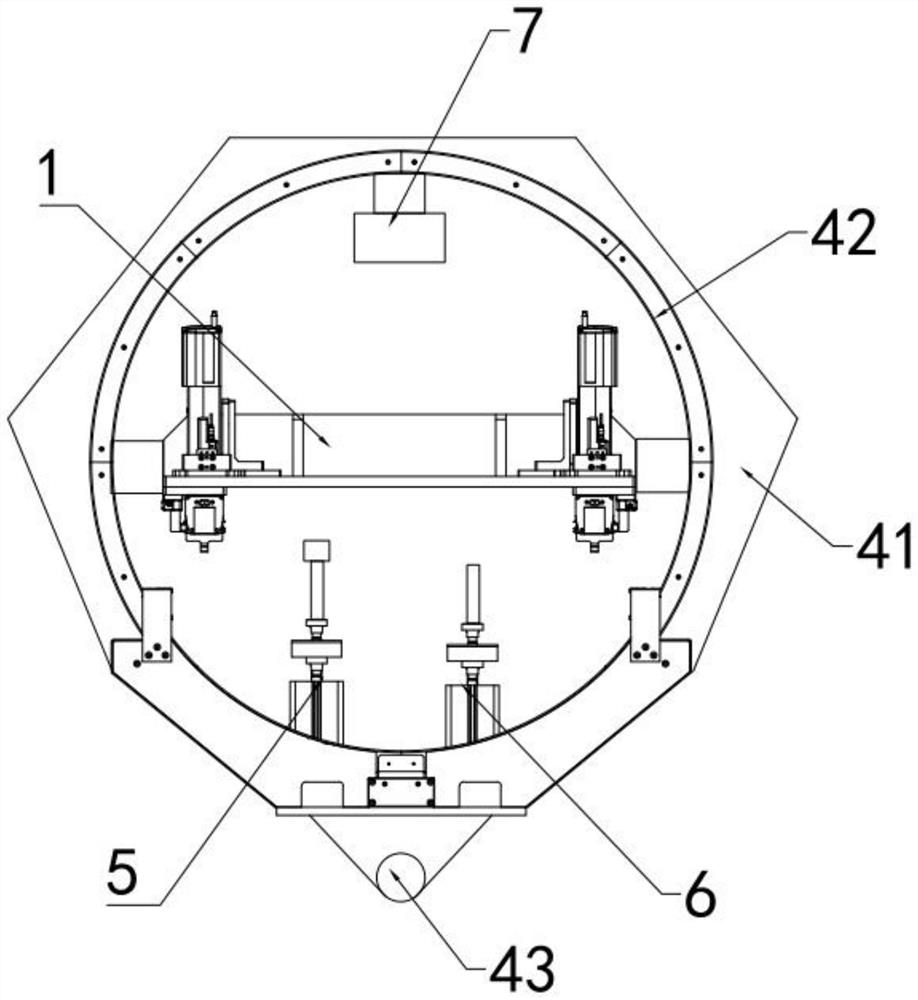

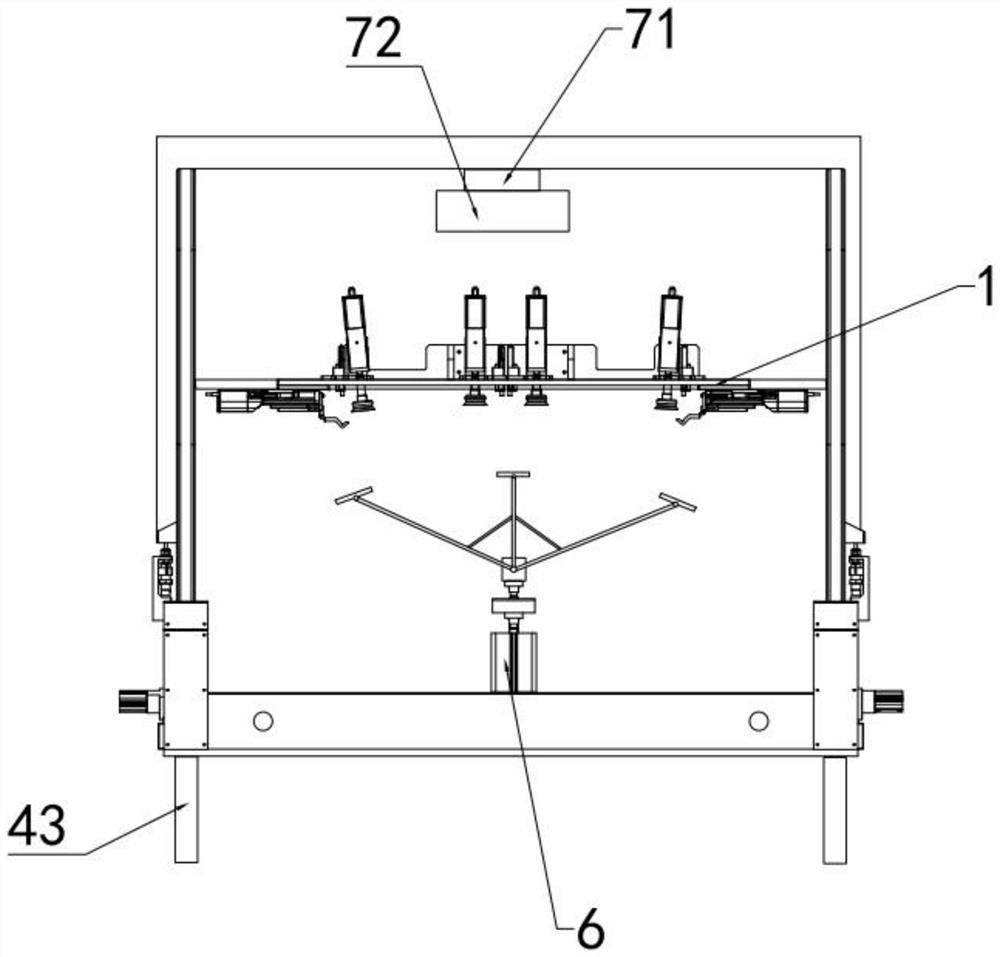

[0028] Example: see Figure 1 to Figure 7 , This embodiment provides an external feature detection device for an arc-shaped reflector, which includes a support table 41, a cylindrical rotating seat 42 movably arranged on the support table 41, and used to drive the cylindrical rotation A rotary drive device 43 for rotating the seat 42 , and an arc-shaped reflector fixing device 1 fixed in the cylindrical rotating seat 42 are arranged above the support table 41 corresponding to the arc-shaped reflector fixing device 1 There is a signal uniformity measuring device 7;

[0029] The curved reflector fixing device 1 includes a first mounting seat that is horizontally fixed on the cylindrical rotating seat 42, a first center fixing module that is symmetrically arranged along the vertical center axis of the first mounting seat, and The second central fixing module is provided with a first edge fixing mechanism and a second edge fixing mechanism with opposite driving directions on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com