Ore impurity dust filtering device for mine construction and implementation method thereof

A technology for filtering dust and ore, applied in separation methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of polluting the environment, flying dust, endangering the health of operators, etc., to achieve physical health protection, a good working environment, speed up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

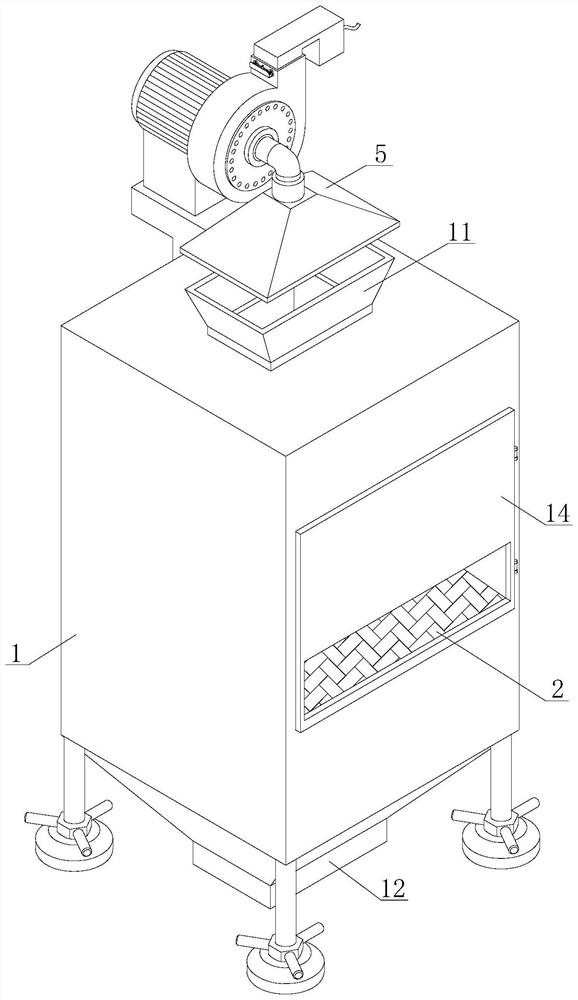

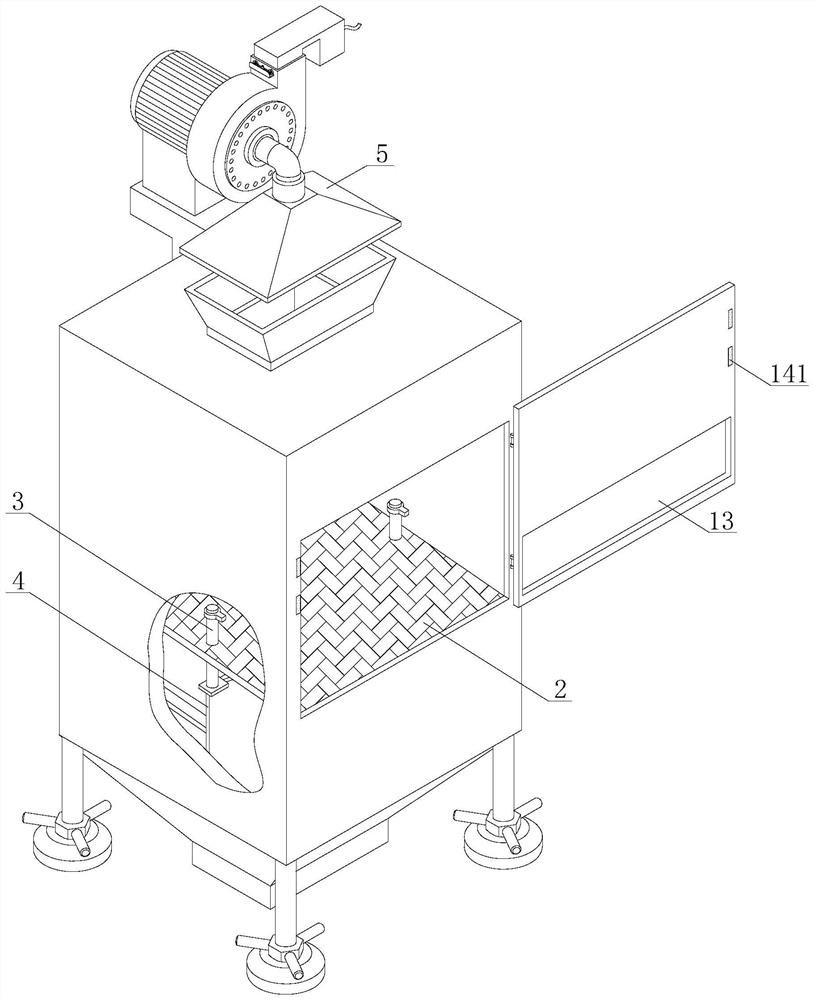

[0047] In order to better demonstrate the implementation process of the ore impurity dust filter device for mine construction, this embodiment now proposes an implementation method of the ore impurity dust filter device for mine construction, including the following steps:

[0048] S10: The ore is put into the dust filter box 1 through the feed port 11 and falls onto the dust filter net 2 under the action of the ore's own gravity;

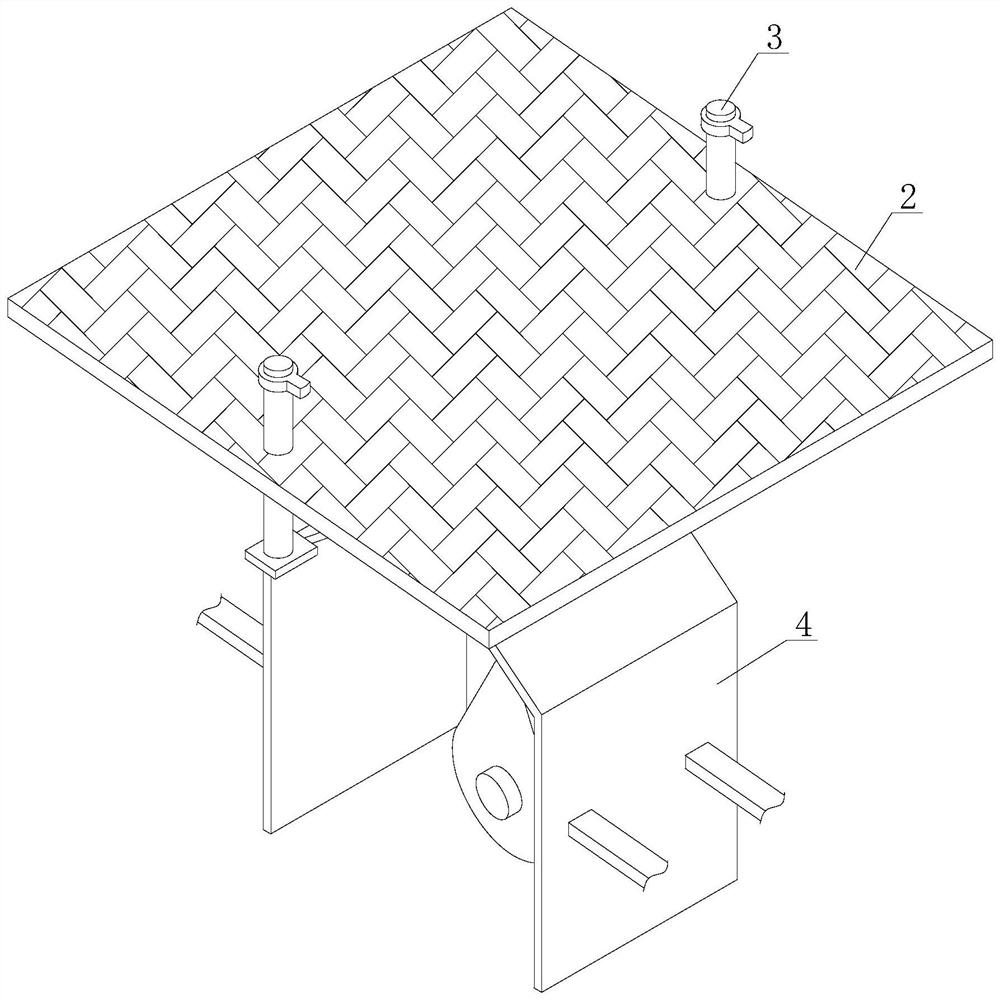

[0049] S20: The driving motor 42 drives the eccentric wheel 43 to rotate, so that the dust filter 2 is continuously raised and lowered under the guidance of the strip guide rod 32 and the ore on the dust filter 2 shakes, and the ore can be filtered through the lifted dust filter 2 ;

[0050] S30: The ore does not pass through the dust filter 2 and is discharged through the discharge port 13 under the drainage of the dust filter 2;

[0051] S40: The ore impurities can pass through the dust filter 2 and be discharged through the discharge port 12 un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com