Closed-loop dynamic matrix control method for continuous stirring reaction kettle

A technology of stirring reaction kettle and closed-loop dynamic, which is applied in the direction of electric controller, controller with specific characteristics, etc., can solve the problem of unable to achieve dynamic characteristics, and achieve the effect of improving closed-loop dynamic, suppressing reverse response, and simple parameter adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

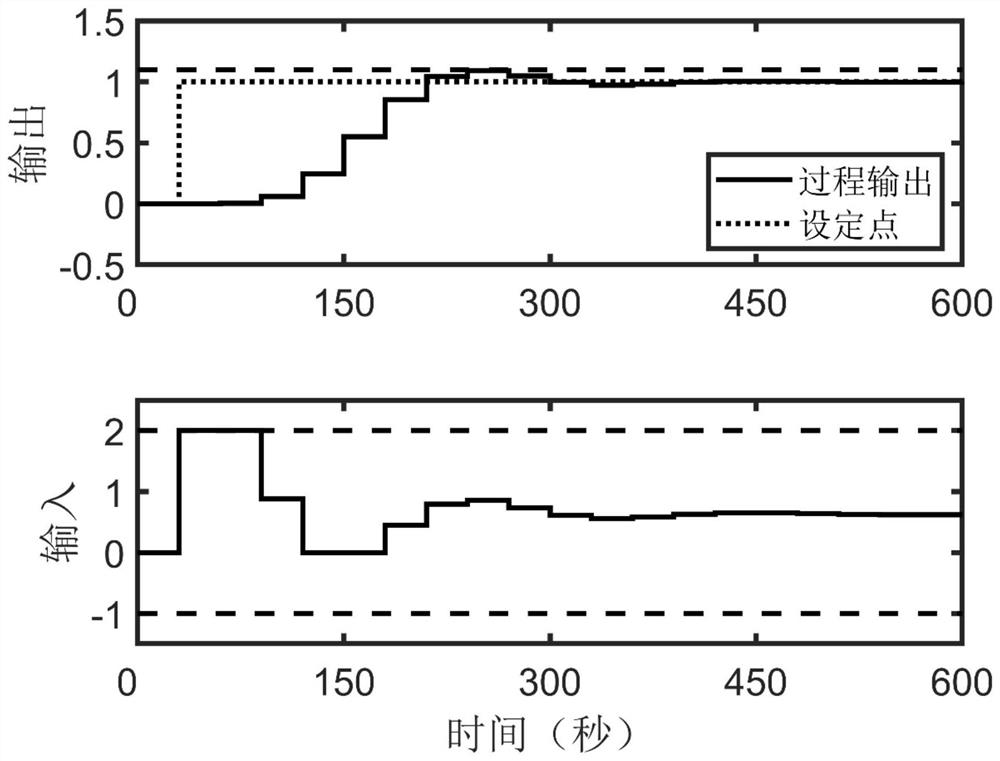

Examples

specific Embodiment approach

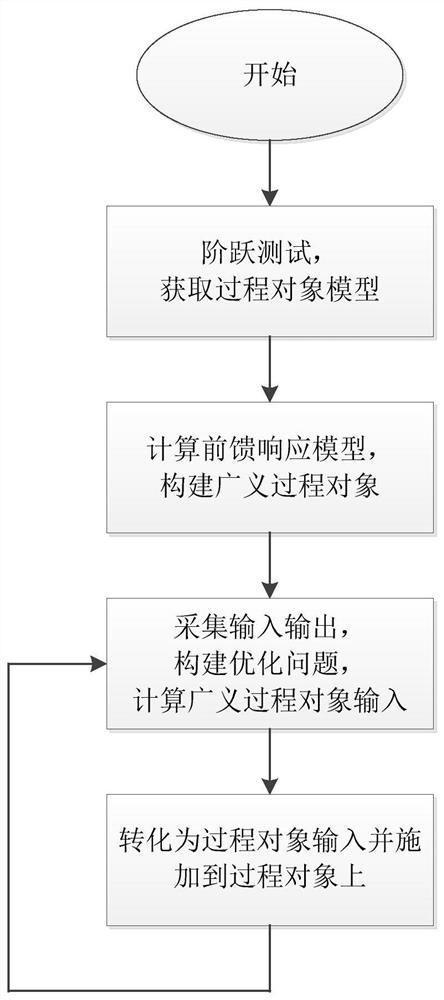

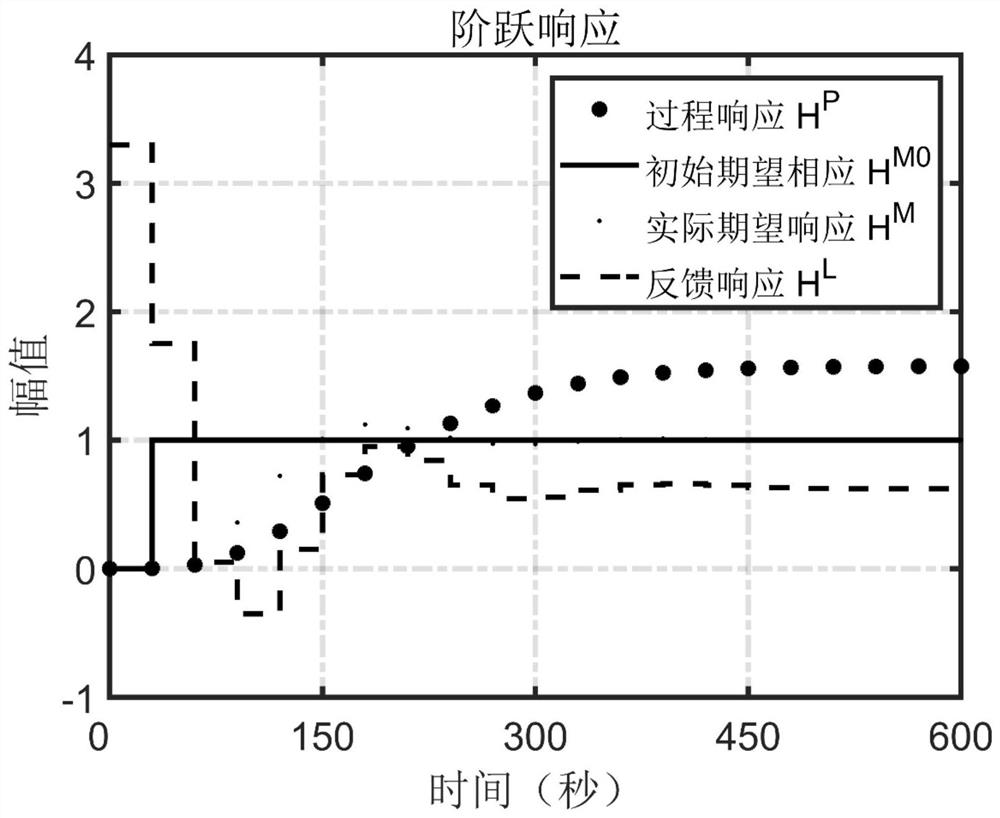

[0052] Step 2, calculate the feed-forward response model offline. Its specific implementation is as follows:

[0053] Step 2-1, firstly determine the desired closed-loop response model, which is set as a step process in this example so as to demonstrate the closed-loop tracking characteristics of the present invention.

[0054] Step 2-2, Solve the optimization problem

[0055]

[0056] s.t.

[0057]

[0058]

[0059] in Represents the feed-forward response model that needs to be optimized, Σ represents the summation, Indicates the jth parameter of the step response model of the process object, Indicates the i-th parameter of the expected closed-loop response model, N m Indicates the model length, which is set to 21 in this example, and β indicates the stability coefficient, which is set to 0.05 in this example.

[0060] Step 2-3, according to the feed-forward response model obtained in step 2-2, determine the actual closed-loop response model in, Indicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com