Automatic discharging system and method for saggars of roller kiln

A technology of automatic unloading and roller kiln, which is applied to the types of furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of inability to realize the limit and inaccurate bead limit, and improve production efficiency and sagger loss rate Low, the effect of reducing impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

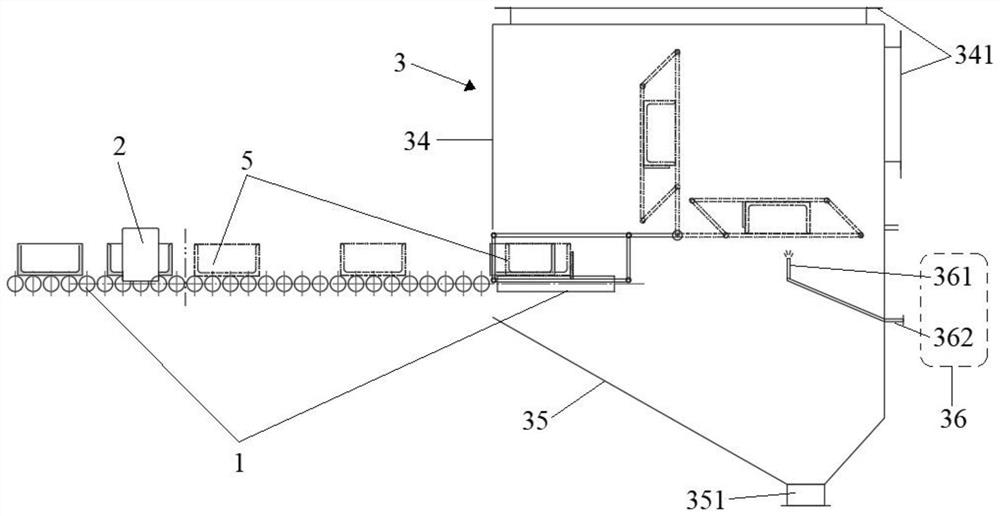

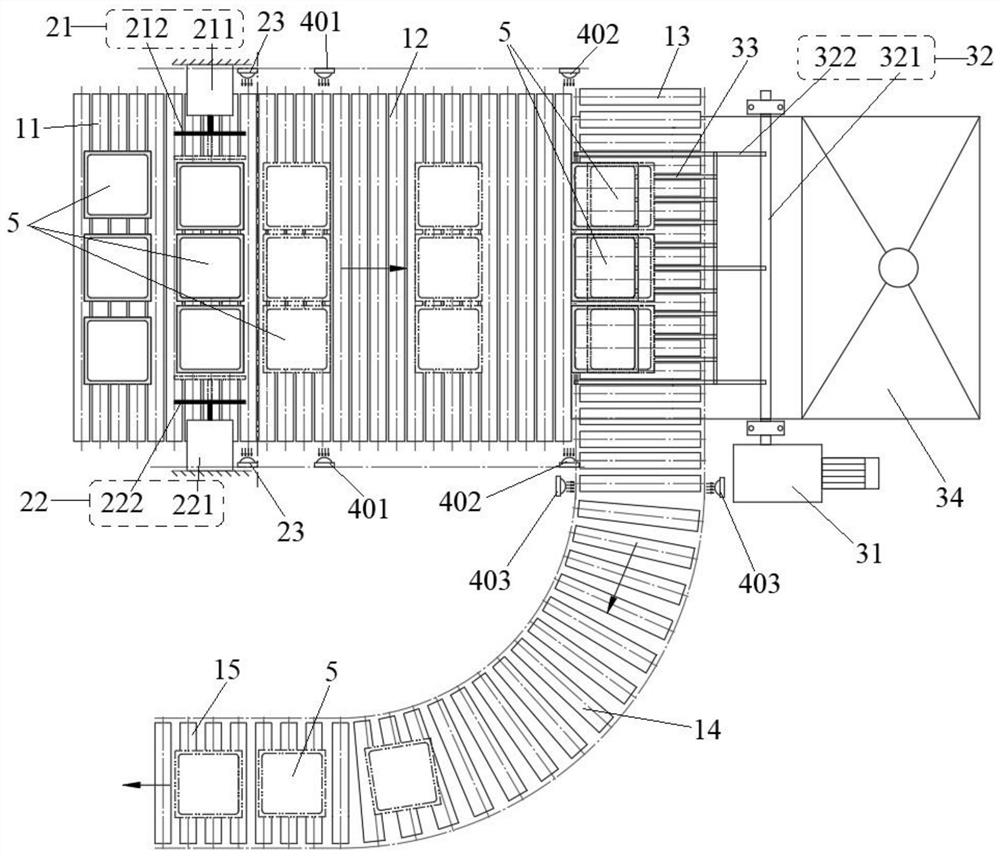

[0119] Such as figure 1 As shown, an automatic unloading system for roller kiln saggers, the system includes: a conveying device 1 , an automatic leveling device 2 and an automatic rotary unloading device 3 . The conveying device 1 includes a first longitudinal conveying roller table 11 , a second longitudinal conveying roller table 12 and a transverse conveying roller table 13 . The second longitudinal conveying roller table 12 is arranged downstream of the first longitudinal conveying roller table 11 , and the front end of the second longitudinal conveying roller table 12 is connected with the end of the first longitudinal conveying roller table 11 . The horizontal conveying roller table 13 is arranged downstream of the second longitudinal conveying roller table 12 , and the end of the second longitudinal conveying roller table 12 is connected to the inner front end of the lateral conveying roller table 13 . The automatic leveling device 2 is arranged on the side of the fi...

Embodiment 2

[0121] Repeat Example 1, such as figure 2 As shown, only the automatic leveling device 2 includes a first leveling mechanism 21 , a second leveling mechanism 22 and a leveling photoelectric switch 23 . The first flattening mechanism 21 and the second flattening mechanism 22 are symmetrically arranged on both sides of the first longitudinal conveying roller table 11 . The leveling photoelectric switch 23 is arranged on the side of the first longitudinal conveying roller table 11 and above the first longitudinal conveying roller table 11 .

Embodiment 3

[0123] Repeat Example 2, except that the first flattening mechanism 21 includes a first cylinder 211 and a first push rod 212; the cylinder body of the first cylinder 211 is fixed on the beam on one side of the first longitudinal conveying roller table 11; The piston rod of the first air cylinder 211 is vertically connected with the first push rod 212 ; the axial direction of the first push rod 212 is perpendicular to the roller table axis direction of the first longitudinal conveying roller table 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com