Roller type conveying equipment used for plate machining

A technology for conveying equipment and sheet metal processing, applied in conveyors, conveyor objects, roller tables, etc., can solve problems such as inability to achieve sheet lift, and achieve the effects of not easy to wear, flexible and adjustable position, and accurate and stable conveying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

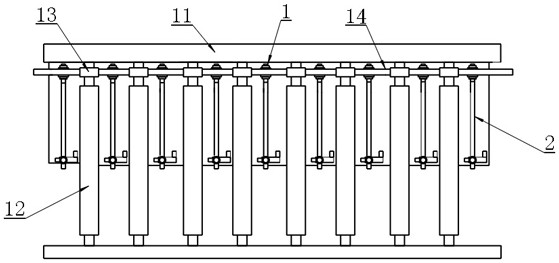

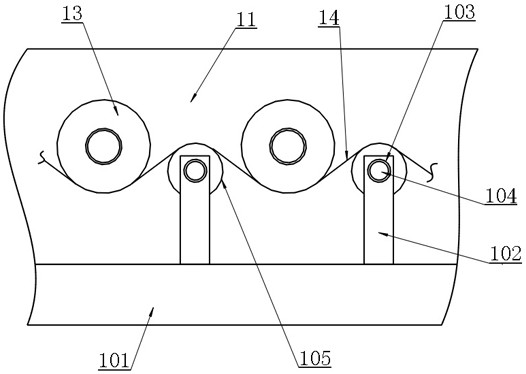

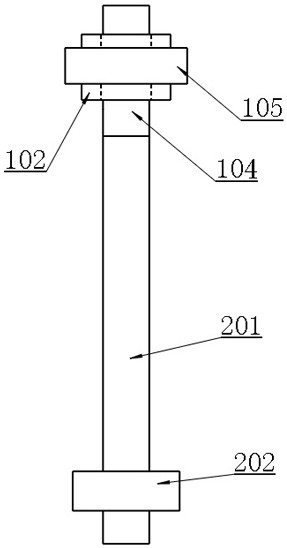

[0026] Example: as attached figure 1 , 2 , 3, 4 and attached Figure 5 As shown, a roller conveying equipment for plate processing includes a stand 11, a roller 12 arranged on the stand 11 and used for conveying the plate a, arranged at the side end of the roller 12 and driving The gear 13 that the roller 12 rotates is arranged at the lower end of the gear 13 and meshes with the chain 14 for power transmission, and also includes a chain 14 that is arranged on the stand 11 and meshes with the chain 14. The transmission unit 1 is arranged at the lower end of the gap between two adjacent rollers 12 and the eccentric wheel unit 2 connected with the transmission unit 1 is arranged at the upper end of the eccentric wheel unit 2 and passed by the eccentric wheel unit 2 The periodic lifting method is used to periodically lift the first li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com