Submerged-arc welding flux recycling and sorting mechanism

A sorting and hopper technology, applied in the field of submerged arc welding flux recovery and sorting mechanism, can solve the problems of cumbersome flux recovery and reuse process, complex and laborious flux classification and screening, and high time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

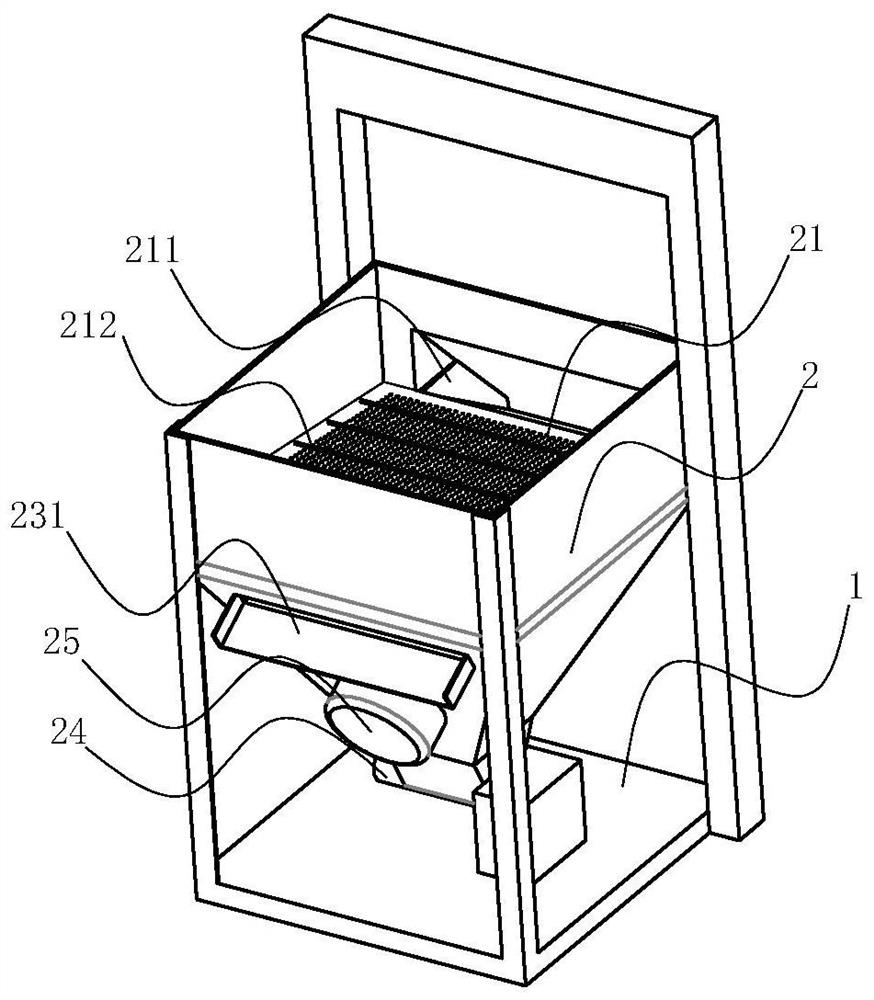

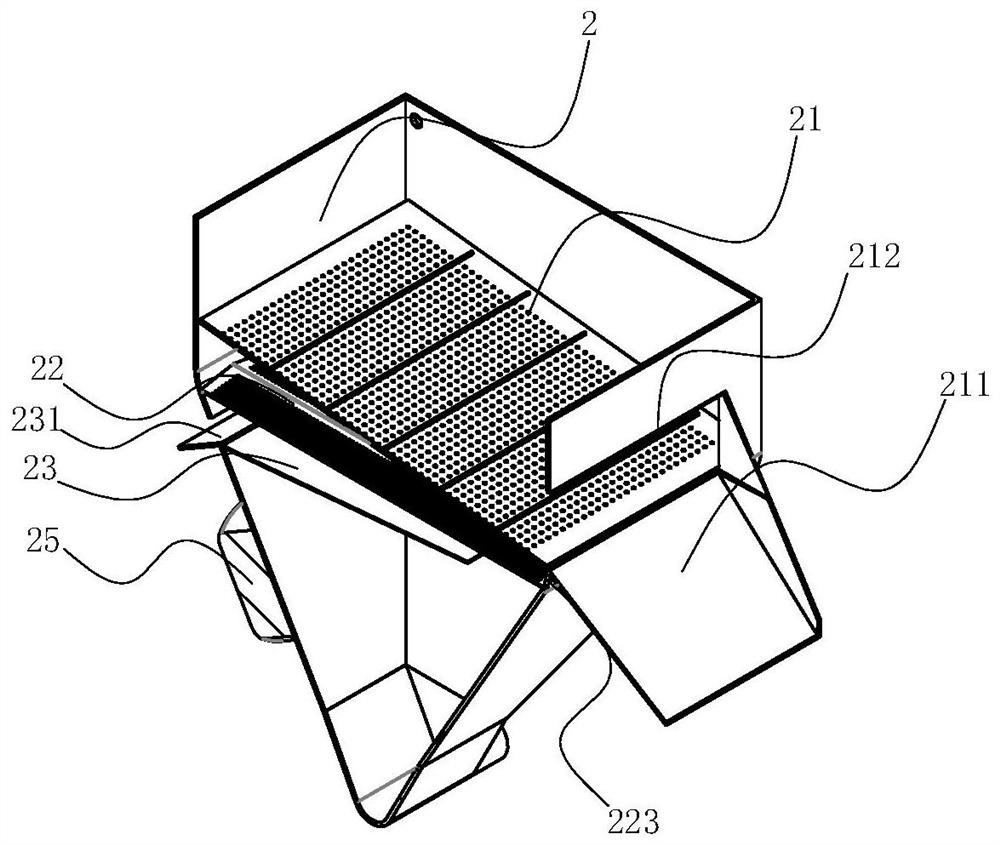

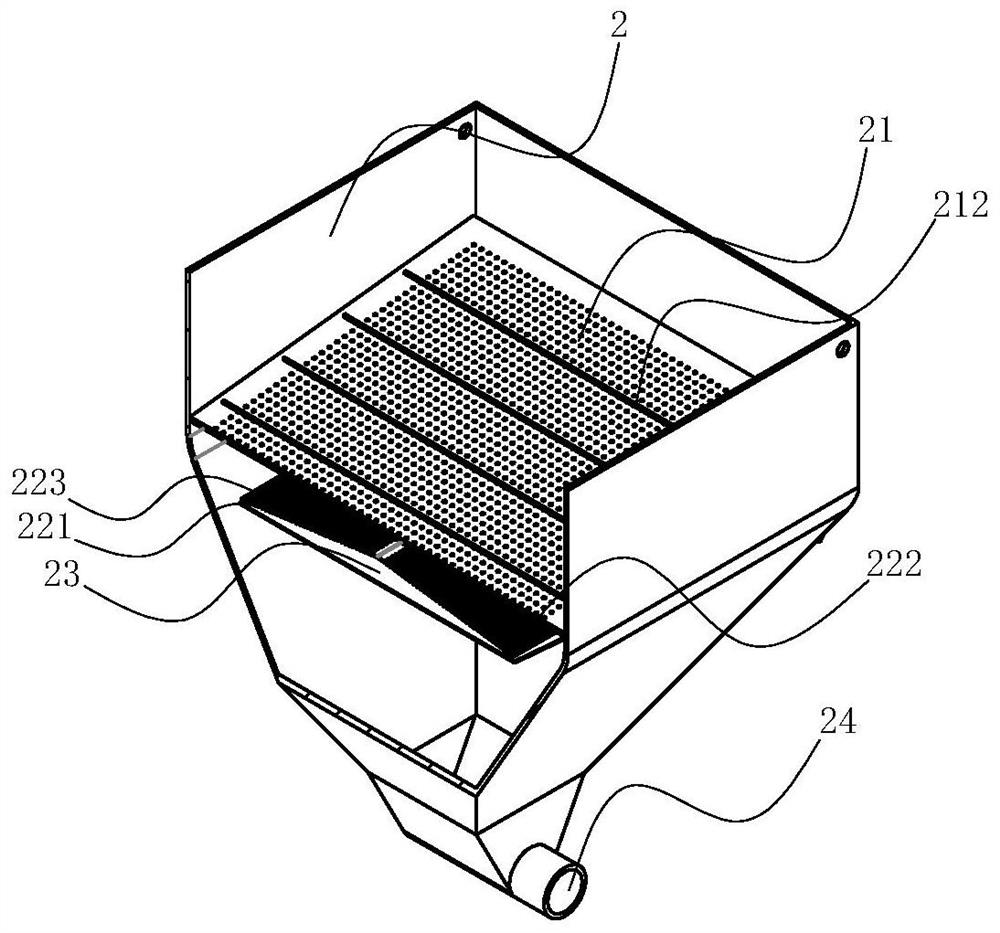

[0016] Such as Figure 1-3 As shown, a submerged arc welding flux recovery and sorting mechanism includes a support frame 1, a hopper 2 is arranged on the support frame 1, and a primary filter screen 21 and a secondary filter screen 22 are sequentially provided in the hopper 2 from top to bottom. A receiving plate 23 is provided below the primary filter screen 22, and the secondary filter screen 22 includes a first inclined portion 221 and a second inclined portion 222 that are respectively arranged symmetrically and slope downward toward both sides. A gap is provided between the inner walls of the hopper 2, and a gap is provided between the lowest point of the second inclined part 222 and the inner wall of the hopper 2. The above-mentioned primary filter screen and secondary filter screen are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com