An integrated demolition and backfill device suitable for underground flexible pipelines and its working method

A technology of flexible pipes and pipes, which is applied in sewer pipe systems, water supply devices, waterway systems, etc., can solve problems such as air shock wave building damage, surrounding environmental pollution, and complicated construction, achieving significant social and economic benefits and wide engineering applications The effects of the foreground and the surrounding environment are small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make those skilled in the art better understand the solutions of the present invention, the technical solutions of the present invention are further described below with reference to specific embodiments.

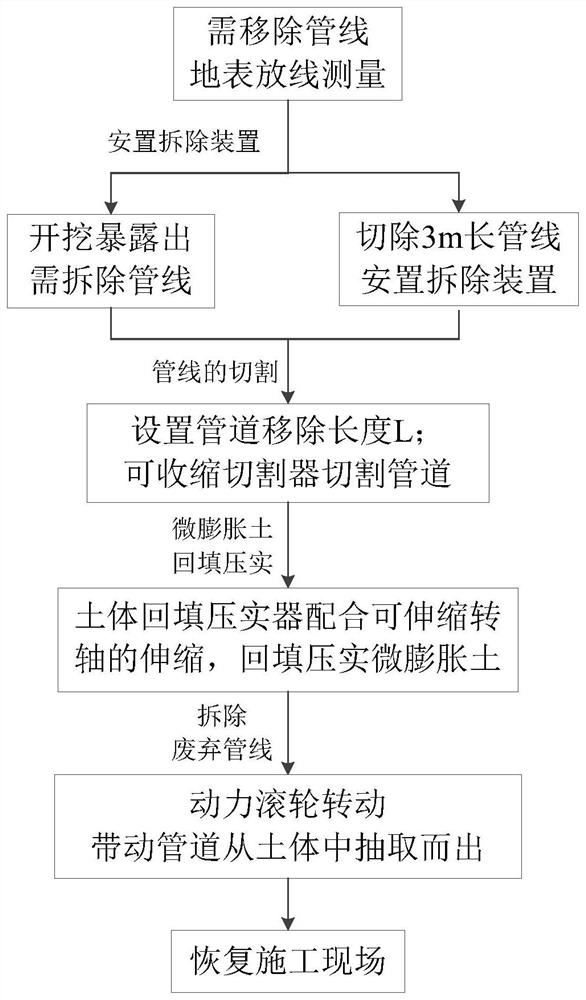

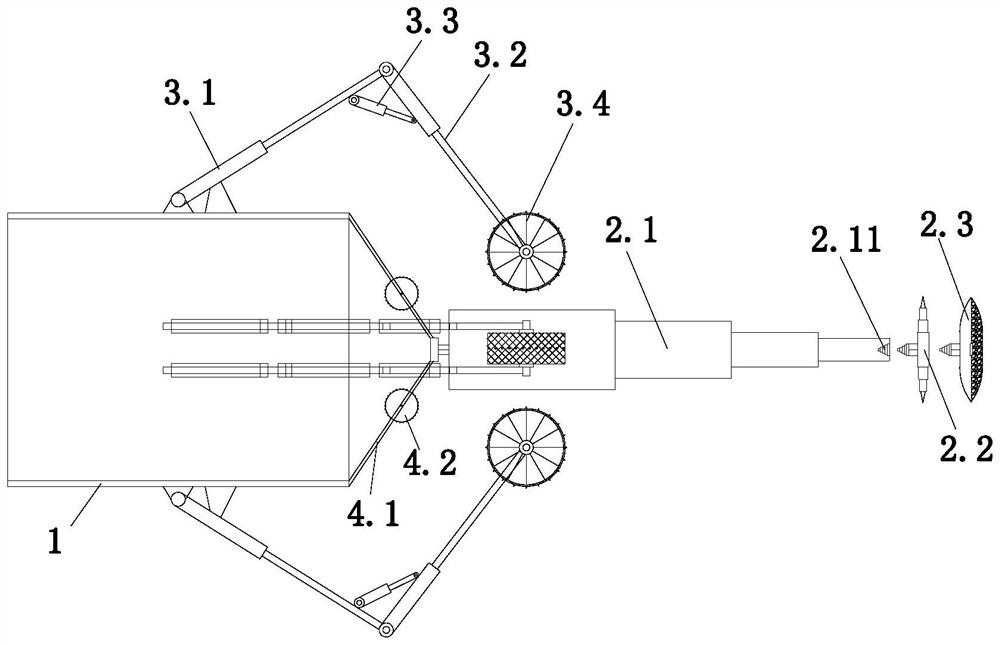

[0044] An integrated demolition and backfilling device suitable for underground flexible pipelines includes a body 1, and a telescopic pipeline cutting and backfilling mechanism, a pipeline withdrawal mechanism and a pipeline decomposition mechanism are arranged on the body 1.

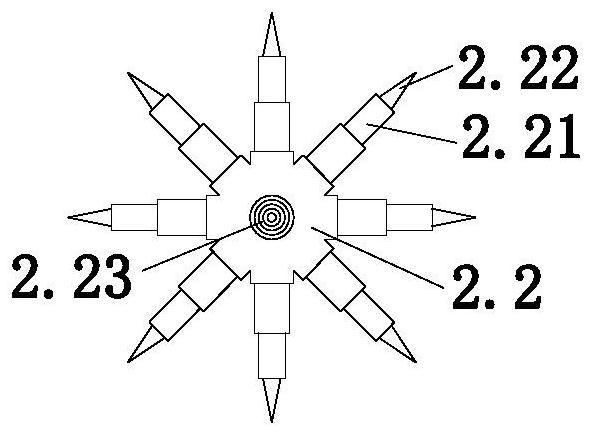

[0045] The telescopic pipe cutting and backfilling mechanism is arranged on one side of the fuselage 1 and includes a telescopic shaft 2.1, a retractable pipe cutter 2.2 and a soil backfilling compactor 2.3, wherein the rear end of the telescopic shaft 2.1 Installed on the fuselage 1, the front end can be installed with the retractable pipe cutter 2.2 or the soil backfill compactor 2.3 according to actual use requirements. see attached Figure 3-4 , the retractable pipe cutter 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com